Abstract

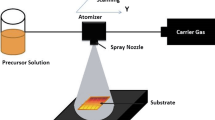

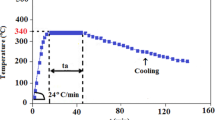

In this work, nanostructured In2O3 thin films with thickness in the range of 40–160 nm were deposited on glass substrates by the chemical spray pyrolysis technique. The microstructural, surface morphology and optical properties were investigated as a function of film thickness through x-ray diffraction, scanning electron microscopy equipped with energy dispersive spectroscopy, atomic force microscopy, Raman spectroscopy, UV–visible spectroscopy and photoluminescence measurements. The x-ray diffraction analysis showed that the deposited films were polycrystalline in nature with a cubic structure having (222) as preferred orientation. The morphological analyses of the samples exhibited uniform and smooth surface of the films with systematical increments in the surface roughness with increasing film thickness. The grain size increased from 9 nm to 13 nm with increasing film thickness. Raman spectroscopy has been employed to study the crystalline quality and the structural disorder of the films. A blue-shift in the energy band gap (E g) from 3.74 eV to 3.98 eV was observed with the increase of film thickness. Moreover, photoluminescence peaks of the In2O3 films appeared at 443 nm and 527 nm for all films. The thickness had a substantial influence on the microstructural and optical properties as well as on the luminescence intensity of the films. The strategy presented here indicates that the prepared films could be suitable candidates for optoelectronic device applications.

Similar content being viewed by others

References

H. Zeng, J.P. Liu, Z.L. Wang, and S. Sun, Nature 420, 395 (2002).

Z. Wang, B. Huang, Y. Dai, X. Qin, X. Zhang, P. Wang, H. Liu, and J. Yu, J. Phys. Chem. C 113, 4612 (2009).

K. Hara, Sol. Energy Mater. Sol. Cells 64, 115 (2000).

R. Katoh, A. Furube, T. Yoshihara, K. Hara, G. Fujihashi, S. Takano, S. Murata, H. Arakawa, and M. Tachiya, J. Phys. Chem. B 108, 4818 (2004).

M.A.M. Khan, W. Khan, M. Ahamed, and M. Alhoshan, Mater. Lett. 79, 119 (2012).

C.W. Dhananjay and C.-W. Chu, Appl. Phys. Lett. 91, 132111 (2007).

D. Zhang, C. Li, X. Liu, S. Han, T. Tang, and C. Zhou, Appl. Phys. Lett. 83, 1845 (2003).

D. Zhang, Z. Liu, C. Li, T. Tang, X. Liu, S. Han, B. Lei, and C. Zhou, Nano Lett. 41, 919 (2004).

J. Ni, H. Yan, A. Wang, Y. Yang, C.L. Stem, A.W. Metz, S. Jim, L. Wang, T.J. Marks, J.R. Ireland, and C. Kannewurf, J. Am. Chem. Soc. 127, 5613 (2005).

S.-E. Lin and W.-C.J. Wei, J. Am. Ceram. Soc. 91, 1121 (2008).

A. Murali, A. Barve, V.J. Leppert, and S.H. Risbud, Nano Lett. 1, 287 (2001).

S. Avivi, Y. Mastai, and A. Gedanken, Chem. Mater. 12, 1229 (2002).

D.P. Dutta, V. Sudarsan, P. Srinivasan, A. Vinu, and A.K. Tyagi, J. Phys. Chem. C 112, 6781 (2008).

W.S. Seo, H.H. Jo, K. Lee, and J.T. Park, Adv. Mater. 15, 795 (2003).

G. Cheng, E. Stern, S. Guthrie, M.A. Reed, R. Klie, Y. Hao, G. Meng, and L. Zhang, Appl. Phys. A 85, 233 (2006).

G. Kiriakidis and N.J. Katsarakis, J. Phys. Condens. Matter 16, S3757 (2004).

D. Chu, Y.-P. Zeng, D. Jiang, and J. Xu, Nanotechnology 18, 435605 (2007).

Y. Zhao, A. Zhang, Z. Wu, and H. Dang, Langmuir 20, 27 (2004).

W.H. Ho, C.F. Li, H.C. Liu, and S.K. Yen, J. Power Sources 175, 897 (2008).

A. Bourlang, D.J. Payne, R.G. Egdell, J.S. Foord, P.P. Edwards, M.O. Jones, A. Schertel, P.J. Dobson, and J.L. Hutchison, Appl. Phys. Lett. 92, 092117 (2008).

C. Matsumoto, J. Suzuki, M. Ohnuma, Y. Kanemitsu, and Y. Matsumoto, Phys. Rev. B 63, 195322 (2001).

M.A.M. Khan, W. Khan, M. Ahamed, M.S. Alsalhi, and T. Ahmed, Electron. Mater. Lett. 9, 53 (2013).

C.Y. Wang, V. Cimalla, H. Romanus, T. Kups, G. Ecke, T. Stauden, M. Ali, V. Lebedev, J. Pezoldt, and O. Ambacher, Appl. Phys. Lett. 89, 011904 (2006).

B.D. Cullity, Elements of X-ray Diffraction, 2nd ed. (Reading, MA: Addison-Wesley, 1978).

G. Yildirim, S. Bal, M. Gulen, A. Varilci, E. Budak, and M. Akdogan, Cryst. Res. Technol. 47, 195 (2012).

G. Yildirim, M. Akdogan, A. Varilci, and C. Terzioglu, Cryst. Res. Technol. 45, 1161 (2010).

W.B. White and V.G. Keramidas, Spectrochim. Acta A 28, 501 (1972).

S. Sahoo, A.P.S. Gaur, A.K. Arora, and R.S. Katiyar, Chem. Phys. Lett. 510, 242 (2011).

A. Singhal, S.N. Achary, J. Manjanna, O.D. Jayakumar, R.M. Kadam, and A.K. Tyagi, J. Phys. Chem. C 113, 3600 (2006).

R. Caracas and R.E. Cohen, Phys. Rev. B 76, 184101 (2007).

O.M. Berengure, A.D. Rodrigues, C.J. Dalmaschio, A.J.C. Lanfredi, E.R. Leite, and A.J. Chiquito, J. Phys. D Appl. Phys. 43, 045401 (2010).

J. Du, M. Yang, S.N. Cha, D. Rhen, M. Kang, and D.J. Kang, Cryst. Growth Des. 8, 2312 (2008).

M.A.M. Khan, S. Kumar, and M.S. AlSalhi, Mater. Res. Bull. 48, 4277 (2013).

M.A.M. Khan, M.W. Khan, M. Husain, and M. Zulfequar, J. Alloys Compd. 486, 876 (2009).

E. Burstein, Phys. Rev. 93, 632 (1954).

S.M. Park, T. Ikegami, K. Ebihara, and P.K. Shin, Appl. Surf. Sci. 253, 1522 (2006).

F. Lai, M. Li, H. Wang, H. Hu, X. Wang, J.G. Hou, Y. Song, and Y. Jiang, Thin Solid Films 488, 314 (2005).

K. Soulantica, L. Erades, M. Sauvan, F. Senooq, A. Maisonnat, and B. Chaudret, Adv. Funct. Mater. 13, 553 (2003).

Y.H. Ng, S. Ikeda, T. Harada, S. Higashida, T. Sakat, H. Mori, and M. Matsumura, Adv. Mater. 19, 597 (2007).

Y. Ohhata, F. Shinoki, and S. Yoshida, Thin Solid Films 59, 255 (1979).

C.-J. Chen, W.-L. Xu, and M.-Y. Chern, Adv. Mater. 19, 3012 (2007).

F. Zeng, X. Zhang, J. Wang, L. Wang, and L. Zhang, Nanotechnology 15, 596 (2004).

C. Liang, G. Meng, Y. Lei, F. Phillipp, and L. Zhang, Adv. Mater. 13, 1330 (2001).

D.A. Magdas, A. Cremades, and J. Piqueras, Appl. Phys. Lett. 88, 113107 (2006).

Y. Li, Y. Bando, and D. Golberg, Adv. Mater. 15, 581 (2003).

C.H. Liang, G.W. Meng, Y. Lei, F. Phillipp, and L.D. Zhang, Adv. Mater. (Weinheim, Ger.) 13, 1330 (2001).

M.J. Zheng, L.D. Zhang, G.H. Li, X.Y. Zhang, and X.F. Wang, Appl. Phys. Lett. 79, 839 (2001).

H.Q. Cao, X.Q. Qiu, Y. Liang, Q.M. Zhu, and M.J. Zhao, Appl. Phys. Lett. 83, 761 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.A.M., Khan, W. Thickness-Dependent Structural and Optoelectronic Properties of In2O3 Films Prepared by Spray Pyrolysis Technique. J. Electron. Mater. 45, 4453–4459 (2016). https://doi.org/10.1007/s11664-016-4618-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4618-y