Abstract

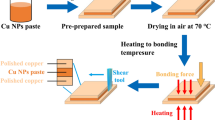

Because of high thermal and electrical conductivity, high melting point, and low cost, bonding by sintering of Cu nanoparticles is promising as a new method to replace the Pb-rich solders currently used in high-temperature applications. However, it is difficult to achieve sufficient strength by using this method because, in the absence of applied pressure, oxidized surfaces inhibit sintering. In this study, we report pressureless bonding of Cu plates with Ni layers by use of Cu and Sn mixed nanoparticles. Bonding was achieved without pressure from 250°C to 350°C in hydrogen by use of pure Cu nanoparticles, and by using mixtures of Cu and Sn nanoparticles in which the amount of Sn varied from 10 to 50 wt.%. The highest strength bonds were obtained by use of Cu–10 wt.% Sn mixed nanoparticles, because the sinterability of the Cu nanoparticles is enhanced by diffusion of Sn into Cu to form an appropriate amount of Cu–Sn intermetallic compounds (IMC) and diminish microvoids. However, when the amount of Sn was greater than 10 wt.%, Cu–Sn IMC were formed to such an extent that the significant reduction of Cu-rich layers led to reduced strength. When the bonding temperature was 350°C, Sn diffused into Cu so much that microvoids were formed in the Sn-rich layer. Because the number of microvoids increased as the amount of Sn was increased, the shear strength could not be enhanced by bonding at higher temperature when the amount of Sn was greater than 30 wt.%.

Similar content being viewed by others

References

K. Suganuma, Curr. Opini. Solid. State Mater. Sci. 5, 55 (2001).

S. Kim, K.-S. Kim, S.-S. Kim, K. Suganuma, and G. Izuta, J. Electron. Mater. 38, 2668 (2009).

S. Kim, K.-S. Kim, S.-S. Kim, K. Suganuma, and G. Izuta, J. Electron. Mater. 38, 873 (2009).

Y. Yamada, Y. Takaku, Y. Yagi, I. Nakagawa, T. Atsumi, M. Shirai, I. Ohmuna, and K. Ishida, Trans. JIEP 2, 79 (2009).

Y. Yamada, Y. Takaku, Y. Yagi, I. Nakagawa, T. Atsumi, M. Shirai, I. Ohmuna, and K. Ishida, Microelectron. Reliab. 47, 2147 (2007).

K. Moon, H. Dong, R. Maric, S. Pothkuchi, A. Hunt, Y. Li, and C.P. Wong, J. Electron. Mater. 34, 168 (2005).

K.S. Siow, J. Electron. Mater. 43, 947 (2014).

K.S. Siow, J. Alloys Comp. 514, 6 (2012).

E. Ide, S. Angata, A. Hirose, and K.F. Kobayashi, Acta Mater. 53, 2385 (2005).

J.G. Bai and G.-Q. Lu, IEEE Trans. Dev. Mater. Reliab. 6, 436 (2006).

P.O. Quintero and F.P. McCluskey, IEEE Trans. Dev. Mater. Reliab. 11, 531 (2011).

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, and C.X. Xu, Appl. Phys. Lett. 97, 153117 (2010).

H. Alarifi, A. Hu, M. Yavuz, and Y.N. Zhou, J. Electron. Mater. 40, 1394 (2011).

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.-S. Kim, and M. Nogi, Microelectron. Reliab. 52, 375 (2012).

Y. Morisada, T. Nagaoka, M. Fukusumi, Y. Kashiwagi, M. Yamamoto, and M. Nakamoto, J. Electron. Mater. 39, 1283 (2010).

Y. Kobayashi, T. Shirochi, Y. Yasuda, and T. Morita, Solid State Sci. 13, 553 (2011).

Y. Kobayashi, T. Shirochi, Y. Yasuda, and T. Morita, Inter. J. Adhes. Adhes. 33, 50 (2012).

J. Yan, G. Zou, A. Hu, and Y.N. Zhou, J. Mater. Chem. 21, 15981 (2011).

T. Ishizaki and R. Watanabe, J. Mater. Chem. 22, 25198 (2012).

H. Nishikawa, T. Hirano, T. Takemoto, and N. Terada, Open Surf. Sci. J. 3, 60 (2011).

T. Yamakawa, T. Takemoto, M. Shimoda, H. Nishikawa, K. Shiokawa, and N. Terada, J. Electron. Mater. 42, 1260 (2013).

G. Q. Lu, J. N. Calata, G. Y. Lei and X. Chen, EuroSimE 2007: 8th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Micro-Electronics and Micro-Systems, 609 (2007).

Y. Morisada, T. Nagaoka, M. Fukusumi, Y. Kashiwagi, M. Yamamoto, M. Nakamoto, H. Kakiuchi, and Y. Yoshida, J. Electron. Mater. 40, 2398 (2011).

R. Durairaj, R. Ashayer, H. R. Kotadia, N. Haria, C. Lorenz, O. Mokhtari and S. H. Mannan, 12th IEEE International Conference on Nanotechnology, 39 (2012).

T. Ishizaki, K. Akedo, T. Satoh, and R. Watanabe, J. Electron. Mater. 43, 774 (2014).

T. Satoh, K. Akedo, and T. Ishizaki, J. Alloy Compd. 582, 403 (2014).

R. Watanabe and T. Ishizaki, Bull. Chem. Soc. Jpn 86, 642 (2013).

T. Ishizaki, T. Satoh, A. Kuno, A. Tane, M. Yanase, F. Osawa, and Y. Yamada, Microelectron. Reliab. 53, 1543 (2013).

J.Y. Kim, J.A. Rodriguez, J.C. Hanson, A.I. Frenkel, and P.L. Lee, J. Am. Chem. Soc. 125, 10684 (2003).

J.T. Richardson, R. Scates, and M.V. Twigg, Appl. Catal. A 246, 137 (2003).

B. Janković, B. Adnađević, and S. Mentus, Chem. Eng. Sci. 63, 567 (2008).

J.A. Rodriguez, J.C. Hanson, A.I. Frenkel, J.Y. Kim, and M. Pérez, J. Am. Chem. Soc. 124, 346 (2002).

U. Tilliander, R.E. Aune, and S. Seetharaman, Z. Metallkd. 97, 72 (2006).

J.F. Li, P.A. Agyakwa, and C.M. Johnson, Acta Mater. 59, 1198 (2011).

T. Fujimoto, T. Ogura and A. Hirose, Mate 2014: 20th Symposium on Microjoining and Assembly Technology in Electronics, 131 (2014) (in Japanese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ishizaki, T., Watanabe, R. Pressureless Bonding by Use of Cu and Sn Mixed Nanoparticles. J. Electron. Mater. 43, 4413–4420 (2014). https://doi.org/10.1007/s11664-014-3368-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3368-y