Abstract

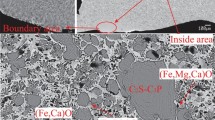

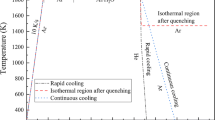

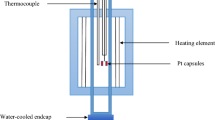

The underutilization of steelmaking slags is primarily ascribed to instability, predominantly influenced by their intricate phase structure. The presence of MgO, a key constituent in steelmaking slag, contributes to the challenges faced in steelmaking slag recycling and sustainable steel production practices. There are currently uncertainties surrounding the impact of fluctuations in MgO content on the mineral phase of steelmaking slag, as well as ongoing controversy regarding the influence of the RO phase on slag stability. This study investigates the phase evolution and microstructures of steelmaking slag with varying MgO contents during the cooling process through high-temperature experiments and FactSage thermodynamic equilibrium calculations. The principal phases in steelmaking slag, namely α′-Ca2SiO4 (C2S), RO (MgO–FeO solid solution), Ca2Fe2O5 (C2F) and Ca3SiO5 (C3S), were identified using XRD and SEM-EDS analyses. As the MgO content increases, the MgO content within the RO continued to increase. With a MgO content of 10 mass pct in steelmaking slag, the precipitation of C3S commences during the cooling of the steelmaking slag. The average size of C3S reaches up to 400 μm, markedly higher than the 35 μm size of C2S. This disparity is attributed to the higher nucleation rate of C2S compared to C3S, coupled with a lower growth rate. The augmentation of MgO content in steelmaking slag induces changes in the C3S formation, facilitated by the substitution of Ca2+ in C3S by Fe2+ and Mg2+.The significance of this work lies in unraveling the intricacies of steelmaking slag behavior, providing crucial insights for optimizing recycling processes. This research sheds light on the factors that influence the phase composition and stability of steelmaking slag, contributing to the utilization of steelmaking slags, promoting environmental sustainability, and bolstering the overall efficiency of metallurgical processes in the current industrial landscape.

Similar content being viewed by others

References

J.L. Guo, Y.P. Bao, and M. Wang: Waste Manag., 2018, vol. 78, pp. 318–30.

Z.J. Wang and I. Sohn: J. Sustain. Metall., 2019, vol. 5, pp. 127–40.

C. Du, X. Gao, and S. Kitamura: J. Sustain. Metall., 2019, vol. 5, pp. 141–53.

M. Oge, D. Ozkan, M.B. Celik, M.S. Gok, and A.C. Karaoglanli: Mater. Today Proc., 2019, vol. 11, pp. 516–25.

A.I. Al-Negheimish, F.H. Al-Sugair, and R.Z. Al-Zaid: J. King Saud. Univ., 1997, vol. 9, pp. 39–54.

M.Y. Benarchid, A. Diouri, A. Boukhari, J. Aride, and I. Elkhadiri: Mater. Chem. Phys., 2005, vol. 94, pp. 190–94.

G. Wang, Y.H. Wang, and Z.L. Gao: J. Hazard. Mater., 2010, vol. 184, pp. 555–60.

A.S. Brand and J.R. Roesler: Cem. Concr. Compos., 2018, vol. 86, pp. 117–29.

F. Wachsmuth, J. Geiseler, W. Fix, K. Koch, and K. Schwerdtfeger: Can. Metall. Q., 1981, vol. 20, pp. 279–84.

K. Nakase, A. Matsui, N. Kikuchi, and Y. Miki: ISIJ Int., 2017, vol. 57, pp. 1197–204.

I. Akinwumi: Period. Polytech Civ. Eng., 2014, vol. 58, pp. 371–77.

C.J. Shi: J. Mater. Civ. Eng., 2004, vol. 16, pp. 230–36.

H.F. Yu, X. Lu, T. Miki, K. Matsubae, Y. Sasaki, and T. Nagasaka: Resour. Conserv. Recycl., 2022, vol. 180, 106203.

M.A. Tayeb, A.N. Assis, S. Sridhar, and R.J. Fruehan: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1112–14.

I.Z. Yildirim and M. Prezzi: Adv. Civ. Eng., 2011, vol. 2011, pp. 1–3.

Z.M. Chen, R. Li, X.M. Zheng, and J.X. Liu: Cem. Concr. Res., 2021, vol. 139, 106271.

M.S. Tang, M.Q. Yuan, S.F. Han, and X. Shen: J. Chin. Ceram. Soc., 1979, vol. 7, pp. 35–46.

Q. Wang and P.Y. Yan: Constr. Build. Mater., 2010, vol. 24, pp. 1134–40.

X. Liu, D.Z. Wang, Z.W. Li, W. Ouyang, Y.P. Bao, and C. Gu: J. Mater. Res. Technol., 2023, vol. 23, pp. 2362–70.

G.R. Qian, D.D. Sun, J.H. Tay, and Z.Y. Lai: Br. Ceram. Trans., 2002, vol. 101, pp. 159–64.

C. Li, J.T. Gao, Z.C. Guo: 7th International Symposium on High-Temperature Metallurgical Processing, TMS, 2016, pp. 85–86

W. Fix, H. Heymann, and R. Heinke: J. Am. Ceram. Soc., 1969, vol. 52, pp. 346–47.

S.H. Ma, W.Q. Zhou, S.P. Wang, W.F. Li, and X.D. Shen: Phase Transit., 2015, vol. 88, pp. 888–96.

A. Merchant, S. Batzner, S.S. Schoenholz, M. Aykol, G. Cheon, and E.D. Cubuk: Nature, 2023, vol. 624, pp. 80–85.

D. Turnbull: Contemp. Phys., 1969, vol. 10, pp. 473–88.

X. Zhang, B. Xie, J. Diao, and X.J. Li: Ironmak. Steelmak., 2012, vol. 39, pp. 147–54.

K.A. Jackson, The Interface Kinetics of Crystal Growth Processes, Kluwer Academic Publishers. Netherlands, 2002, pp. 175–99.

J.C. Li, G.X. Li, F. Qiu, R. Wang, J.S. Liang, Y. Zhong, D. Guan, J.W. Li, S. Sridhar, and Z.S. Li: Int. J. Miner. Metall. Mater., 2023, vol. 30, pp. 378–87.

K.C. Mills and S. Sridhar: Ironmak. Steelmak., 1999, vol. 26, pp. 262–68.

W.W. Xuan, S. Guhl, Y.Q. Zhang, J.S. Zhang, and B. Meyer: Ceram. Int., 2022, vol. 48, pp. 28291–98.

S.A. D’Souza, S. Banik, H.B. Vuthaluru, and S.V. Pisupati: Fuels, 2021, vol. 2, pp. 37–47.

W. Huang and Y. Liu: ISIJ Int., 2020, vol. 60, pp. 2183–90.

J. Diao, W. Zhou, P. Gu, Z.Q. Ke, Y. Qiao, and B. Xie: CrystEngComm, 2016, vol. 18, pp. 6272–81.

D.L. Ye and J.H. Hu: Practical Inorganic Thermodynamic Data Handbook, 2nd ed. Metallurgical Industry Press, Beijing, 2002, pp. 217–21.

M.C. Weinberg, D.P. Birnie, and V.A. Shneidman: J. Non-Cryst. Solids, 1997, vol. 219, pp. 89–99.

G. Ruitenberg, E. Woldt, and A.K. Petford-Long: Thermochim. Acta, 2001, vol. 378, pp. 97–105.

M. Fanfoni and M. Tomellini: Il Nuovo Cimento D, 1998, vol. 20, pp. 1171–82.

Acknowledgments

This work was supported by the Natural Science Foundation of Chongqing, China (cstc2022ycjh-bgzxm0003). The China Scholarship Council (CSC) is gratefully acknowledged for providing one of the authors (Wen-Feng Gu) with a scholarship as a visiting PhD student (Registered Number: 202206050118).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

In this model, the steelmaking slag compositions are classified into three categories: glass formers (XG); modifiers (XM), and amphoterics (XA).

The model assumes Weymann–Frenkel relation

where A and B are composition dependent parameters. The parameter B can be expressed by the third-order polynomial equation (A6), where B0, B1, B2 and B3 can be obtained by equations (A7) through (A10).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, WF., Diao, J., Lai, ZQ. et al. Effect of MgO on Phase Structure and Evolution of Steelmaking Slag During Cooling. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03116-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03116-z