Abstract

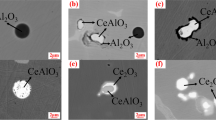

Rare earth element treatment is one of the most promising methods to solve problems in the metallurgical process of high-Al steel. 6.3 pct Al ferritic steel was prepared and treated with 0.04 pct Ce under laboratory conditions. The inclusions in the steel before and after Ce-treatment were observed by SEM-EDS. After Ce addition, CeS and Ce2O2S inclusions were produced in the steel. The modification mechanism of Ce on inclusions was studied by thermodynamic analysis and mismatch calculation. The Al2O3 inclusions were modified into CeS–CeAlO3–Al2O3 and CeS–CeAlO3, in which the CeAlO3 is generated by the reaction of Al2O3 and dissolved Ce, and the CeS precipitates on the surface of Al2O3 and CeAlO3 by heterogeneous nucleation. The AlN inclusions were modified into single-particle and aggregated CeS–AlN by heterogeneous precipitation on the surface of CeS. Furthermore, the aggregation of AlN was analyzed based on the cavity bridge theory, and the relationship between the critical aggregation distance and the particle radius of AlN is \({d}_{\text{C, AlN}}\text{ = 0.134}{\left({r}_{{\text{P}}_{1}}{r}_{{\text{P}}_{2}}\right)}^{0.5}\text{ - 0.02}\left({r}_{{\text{P}}_{1}}\text{ + }{r}_{{\text{P}}_{2}}\right)\). The promoting effects of CeS on the AlN aggregated process are as follows: I. increasing the amount of nucleation point and precipitation temperature of AlN; II. increasing the initial equivalent radius of AlN particles; and III. CeS–AlN acts as the core during multiple aggregation processes with AlN.

Similar content being viewed by others

References

S. Khaple, B.R. Golla, and V.V.S. Prasad: Def. Technol., 2023, vol. 26, pp. 1–22.

P.C. Liu, J.H. Cong, Z.X. Wang, X.L. Shang, X.Y. Xu, R.D.K. Misra, C.J. Shang, and X.M. Wang: Mater. Lett., 2021, vol. 302, 130388.

Y. Guo, L. Cao, G. Wang, and C. Liu: Metall. Mater. Trans. B, 2023, vol. 54B, pp. 275–86.

M. Alba, M. Nabeel, and N. Dogan: Steel Res. Int., 2020, vol. 91, p. 1900477.

M. Nabeel, M. Alba, A. Karasev, P.G. Jönsson, and N. Dogan: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1674–85.

S. He, G. Chen, Y. Guo, B. Shen, and Q. Wang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 585–94.

H. Liu, J. Liu, S. Michelic, F. Wei, C. Zhuang, Z. Han, and S. Li: Ironmak. Steelmak., 2016, vol. 43, pp. 171–79.

B. Li, H. Zhu, J. Zhao, M. Song, J. Li, and Z. Xue: Steel Res. Int., 2022, vol. 93, p. 2100347.

X. Wang, G. Li, Y. Liu, F. Wang, and Q. Wang: ISIJ Int., 2021, vol. 61, pp. 1850–59.

Y. Wang and C. Liu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2585–95.

Y. Li, G. Yang, Z. Jiang, C. Chen, S. Sun, and P. Du: Ironmak. Steelmak., 2020, vol. 47, pp. 67–76.

R. Geng, J. Li, and C. Shi: ISIJ Int., 2021, vol. 61, pp. 1506–13.

H. Wang, Y. Niu, H. Ling, J. Qiao, Y. Zhang, W. Zhong, and S. Qiu: Metals, 2023, vol. 13, p. 453.

C.Y. Zhu, X.H. Chen, L.F. Zhang, X.Y. Liang, and F. Zhang: Mater. Sci. Forum, 2016, vol. 852, pp. 38–48.

Y. Wang and C. Liu: ISIJ Int., 2022, vol. 62, pp. 1852–61.

H. Duan, Y. Ren, and L. Zhang: Chem. Eng. Sci., 2019, vol. 196, pp. 14–24.

J. Wang, L. Zhang, Y. Zhang, Q. Ren, and H. Duan: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2831–36.

Q. Long, W. Wang, and X. Gao: Metall. Mater. Trans. B, 2023, vol. 54B, pp. 2552–63.

X. Zang, C. Liu, J. Qiu, and Y. Wang: J. Mater. Res. Technol., 2023, vol. 25, pp. 2251–60.

W. Wang, H. Zhu, Y. Han, J. Li, and Z. Xue: Ironmak. Steelmak., 2021, vol. 48, pp. 1038–47.

K. Chen, D. Wang, D. Hou, T. Qu, J. Tian, and H. Wang: ISIJ Int., 2019, vol. 59, pp. 1735–43.

K. Sasai: ISIJ Int., 2014, vol. 54, pp. 2780–89.

K. Sasai: ISIJ Int., 2016, vol. 56, pp. 1013–22.

L. Cao, G. Wang, X. Yuan, P. Jin, and S. Sridhar: Metals, 2019, vol. 9, p. 900.

H. Duan, Y. Ren, B.G. Thomas, and L. Zhang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 36–41.

D. Liu, Z. Xue, and S. Song: Steel Res. Int., 2023, vol. 94, p. 2200551.

J. Wang, S. Song, Z. Xue, D. Tang, G. Tong, and D. Liu: J. Iron Steel Res. Int., 2023, vol. 30, pp. 350–62.

D.-H. Kim, M.-S. Jung, H. Nam, M.-K. Paek, and J.-J. Pak: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1106–12.

G.K. Sigworth and J.F. Elliott: Met. Sci., 1974, vol. 8, pp. 298–310.

Q. Ren, L. Zhang, Z. Hu, and L. Cheng: Ironmak. Steelmak., 2021, vol. 48, pp. 191–99.

B.L. Bramfitt: Metall. Trans., 1970, vol. 1, pp. 1987–95.

W.M. Yim and R.J. Paff: J. Appl. Phys., 1974, vol. 45, pp. 1456–57.

W.T. Fu and D.J.W. Ijdo: J. Solid State Chem., 2006, vol. 179, pp. 2732–38.

Y.P. Ji, Y.M. Li, M.X. Zhang, W. Qu, T.X. Zhao, and H.P. Ren: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 1707–18.

Y. Luo, M. Li, P.R. Scheller, S. Sridhar, and L. Zhang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2459–70.

J. Wang, L. Wang, C. Li, and Y. Zhai: J. Rare Earths, 2022.

S.K. Michelic and C. Bernhard: Steel Res. Int., 2022, vol. 93, p. 2200086.

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (Grant No. U1860106), and the Fundamental Research Funds for the Central Universities (No. FRF-BD-23-01) for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Guo, S., Wang, R. et al. Modification Mechanism of Ce-Treatment on Inclusions in High-Al Ferritic Steel. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03045-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03045-x