Abstract

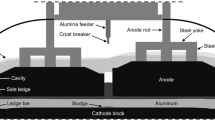

A computational fluid dynamics (CFD) model was developed based on the start-up, operation, and temperature fluctuations of the industrial aluminum electrolysis cell to forecast the shape, thickness, and transient behavior of the whole-cell side ledge. Results indicate a strong correlation between the shape and thickness of the side ledge and melt flow. Driven by electromagnetic force (EMF) and bubble disruption, the side ledge attached to the electrolyte is rough and uneven, whilst the toe adjacent to the metal is flatter. The modeling reliability is validated against autopsy and test data in an industrial cell. During the anode effect (AE), the electrolyte temperature and superheat increase significantly and return to normal after 30 min. The side ledge demonstrates a rapid response to the overheating, with a melting speed of 0.02 m3 K−1 within 30 seconds AE, and the side ledge volume is reduced by 16.9 pct to the minimum value after AE. The side ledge can self-regulate against thermal fluctuation, but it needs a long time to recover. The modeling results also show that during the AE, adjusting the thermal balance by enhancing the external convective heat transfer is insufficient in a short time and that other strategies should be implemented.

Similar content being viewed by others

Change history

14 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11663-023-02831-3

References

R.K. Jain, M.P. Taylor, S.B. Tricklebank, and B.J. Welch: Molten Salt Chem. Technol., 1982, vol. 59, pp. 59–64.

W. Choate and J. Green: Light Metals, TMS, San Diego, CA, 2006, pp. 1070–75.

A. Solheim: Light Metals, TMS, San Diego, CA, 2011, pp. 381–86.

V.A. Khokhlov, E.S. Filatov, A. Solheim, and J. Thonstad: Light Metals, TMS, Warrendale, PA, 1998, pp. 501–06.

D.S. Severe and V. Gusberti: Light Metals, TMS, Warrendale, PA, 2009, pp. 309–14.

M. Dupuis: Light Metals, TMS, Warrendale, PA, 1998, pp. 409–17.

M. Dupuis: Light Metals, TMS, Warrendale, PA, 1994, pp. 339–42.

M. Dupuis: Light Metals, TMS, Nashville, TN, 2000, pp. 297–302.

S. Yang, J. Li, H.L. Zhang, Z. Zou, and Y.Q. Lai: Chin. J. Nonferrous Met., 2017, vol. 27, pp. 162–70. (in Chinese).

M. Dupuis and V. Bojarevics: Light Metals, TMS, San Francisco, CA, 2005, pp. 499–54.

M. Dupuis, V. Bojarevics, and J. Freibergs: Light Metals, TMS, Charlotte, NC, 2004, pp. 453–60.

M.V. Romerio, M. Flueck, J. Rappaz, and Y. Safa: Light Metals, TMS, San Francisco, CA, 2005, pp. 461–68.

Y. Safa, M. Flueck, and J. Rappaz: Appl. Math Model., 2009, vol. 33, pp. 1479–92.

H.L. Zhang, L. Ran, J.D. Liang, T.S. Li, K.N. Sun, and J. Li: Light Metals, TMS, Phoenix, AZ, 2018, pp. 587–96.

V. Bojarevics and K. Pericleous: Light Metals, TMS, Warrendale, PA, 2009, pp. 569–74.

P. Zhou, C. Meiand, and N.J. Zhou: Acta Metall. Sin, 2004, vol. 40, pp. 77–82. (in Chinese).

V.R. Voller and C. Prakash: Int. J. Heat Mass Transfer., 1987, vol. 30, pp. 1709–19.

A. Fallah-Mehrjardi, P.C. Hayes, and E. Jak: Metall Mater. Trans. B, 2014, vol. 45B, pp. 1232–47.

M.P. Taylor, B.J. Welch and M.J. O'Sullivan: Chemeca 83, Proceedings of the Eleventh Australian Chemical Engineering Conference, Brisbane, 1983, pp. 493–500.

M.P. Taylor, B.J. Welch, and J.T. Keniry: J. Electroanal. Chem. Interf. Electrochem., 1984, vol. 168, pp. 179–92.

A. Solheim, H. Gudbrandsen, and S. Rolseth: Light Metals, TMS, Warrendale, PA, 2009, pp. 411–19.

M.M. Ali and H. Kvande: JOM, 2017, vol. 69, pp. 266–80.

J. Liu, M. Taylor, and M. Dorreen: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 238–51.

J. Liu, S. Wei, and M. Taylor: JOM, 2019, vol. 71, pp. 514–21.

P. Lavoie, S. Namboothiri, M. Dorreen, J.J. Chen, D.P. Zeigler, and M.P. Taylor: Light Metals, TMS, Warrendale, PA, 2011, pp. 367–74.

S. Namboothiri, P. Lavoie, D. Cotton, and M.P. Taylor: Light Metals, TMS, Warrendale, PA, 2009, pp. 317–22.

H. Zhang, L. Ran, Z. Zou, G. He, Y. Tang, and J. Li: J. Sustain. Metall., 2018, vol. 4, pp. 359–66.

Acknowledgments

This work was financially supported by the National Key R&D Program of China (No. 2022YFB3304902), the Science and Technology Planning Project of Yunnan Province (No.202202AB080017), the Joint Fund of National Natural Science Foundation of China (No. U2202253), the Strategic Research and Consulting Project of Chinese Academy of Engineering (No. 2022-XY-143), the Frontier Cross Project of Central South University (No. 2023QYJC007), and the Postgraduate Scientific Research Innovation Project of Hunan Province (No. CX20220223).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ran, L., Wang, Q., Li, J. et al. Improved CFD Modeling of the Whole-Cell Side Ledge Behavior in Aluminum Electrolysis Cell. Metall Mater Trans B 54, 1122–1130 (2023). https://doi.org/10.1007/s11663-023-02747-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02747-y