Abstract

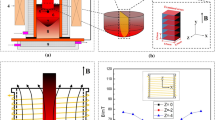

The current study focuses on the influences of magnetic flux density (MFD) on liquid melt film (LMF) morphology and inclusion removal during magnetic controlled electroslag remelting (MC-ESR) process (GCr15 bearing steel). The average thickness of LMF was reduced by 21.0, 33.0 and 41.3 pct, respectively, after applying a 35, 65 and 95 mT transverse static magnetic field (TSMF). This phenomenon can be attributed to the accelerated dynamic process (LMF aggregating to form droplet and droplet dripping) under TSMF condition, which was more obvious as larger MFD was applied. In addition, the kinetic conditions for inclusion removal in LMF were also enhanced with the increase of the MFD (0 to 95 mT), leading to a gradual decrease in the number and size of inclusions in LMF. This work highlights the LMF morphology tailoring and inclusions removal enhancement by regulating the MFD of applied TSMF as well as guides the industrial application of MC-ESR technology.

Similar content being viewed by others

References

[1] L. Zhang, B.G. Thomas: Metall. Mater. Trans. B, 2006, vol. 37, pp. 733-61.

[2] H.B. Xue, Y.F. Cheng: Corros. Sci., 2011, vol. 53, pp. 1201-08.

[3] T. Atkins: J. Mater. Process. Technol., 2018, vol. 261, pp. 280-94.

[4] J. Fu: Acta Metall. Sin., 1979, vol. 15, pp. 526-39.

[5] Z.B. Li, W.H. Zhou, and Y.D. Li: Iron Steel, 1980, vol. 01, pp. 20-26.

[6] D. Zhan, Z. Yangpeng, R.J. Liu, Z.H. Jiang, and H.S. Zhang: Iron. Steel., 2016, vol. 44, pp. 1-9.

[7] Y. Liu, X. Wang, G. Li, Q. Wang, Z. Zhang, and B. Li: Vacuum, 2018, vol. 154, pp. 351-58.

[8] Z.H. Jiang, D. Hou, Y. Dong, Y. Cao, H.B. Cao, and W. Gong: Metall. Mater. Trans. B, 2016, vol. 47, pp. 1465-74.

[9] D. Hou, Z.H. Jiang, Y. Dong, W. Gong, Y. Cao, and H.B. Cao: ISIJ Int., 2017, vol. 57, pp. 1400-09.

[10] G. Du, J. Li, and Z.B. Wang: ISIJ Int., 2018, vol. 58, pp. 78-87.

[11] C. Shi, W.T. Yu, H. Wang, J. Li, and M. Jiang: Metall. Mater. Trans. B, 2016, vol. 48, pp. 146-61.

[12] X.F. Shi, L.Z. Chang, and J.J. Wang: Int. J. Miner. Metall. Mater., 2015, vol. 22, pp. 1033-42.

[13] I.V. Chumanov, M.A. Matveeva, and D.V. Sergeev: Steel in Translation, 2019, vol. 49, pp. 77-81.

[14] H.B. Cao, Z.H. Jiang, Y.W. Dong, F.B. Liu, Z.W. Hou, K. Yao, and J. Yu: ISIJ Int., 2020, vol. 60, pp. 247-57.

[15] Y.F. Qi, J. Li, C.B. Shi, Y. Zhang, Q.T. Zhu, and H. Wang: J. Mater. Process. Technol., 2017, vol. 249, pp. 32-38.

[16] X. Shi, S.C. Duan, W.S. Yang, M.T. Mao, H.J. Guo, and J. Guo: Metall. Mater. Trans. B, 2019, vol. 50, pp. 3072-87.

[17] Y.Y. Kompan, I.V. Protokovilov: Metallic Materials with High Structural Efficiency, Springer, Dayton, 2004, pp. 413-18.

[18] Y. Kompan, I. Protokovilov, Y. Fautrelle, Y. Gelfgat, and A. Bojarevics: Magnetohydrodynamics, 2010, vol. 46, pp. 317-24.

[19] Q. Wang, H. Yan, F. Wang, and B. Li: JOM, 2015, vol. 67, pp. 1821-29.

[20] Y.B. Zhong, L.I. Qiang, Y.P. Fang, H. Wang, M.H. Peng, L.C. Dong, T.X. Zheng, Z.S. Lei, W.L. Ren, and Z.M. Ren: Mater. Sci. Eng. A, 2016, vol. 660, pp. 118-26.

[21] Q. Li, Y.B. Zhong, C.X. Sun, H. Wang, T.X. Zheng, W.L. Ren, and Z.M. Ren: Acta Metall. Sin. (English Letters), 2018, vol. 31, pp. 1311-16.

[22] Q. Li, Z.B. Xia, Y.F. Guo, Z. Shen, T.X. Zheng, and Y.B. Zhong: ISIJ Int., 2020, vol. 60, pp. 2462-70.

[23] Y.F. Guo, Z.B. Xia, Z. Shen, Q. Li, C.X. Sun, T.X. Zheng, W.L. Ren, Z.S. Lei, and Y.B. Zhong: J. Mater. Process. Technol., 2021, vol. 290, pp. 116962.

[24] C.X. Sun, Y.F. Guo, Q. Li, Z. Shen, T.X. Zheng, H. Wang, W.L. Ren, Z.S. Lei, and Y.B. Zhong: Metals, 2020, vol. 10, pp. 647.

[25] Q. Wang, Z. He, G. Li, B. Li, C. Zhu, and P. Chen: Int. J. Heat Mass Transfer, 2017, vol. 104, pp. 943-51.

[26] H. Wang, Y.B. Zhong, Q. Li, W.Q. Li, W.L. Ren, Z.S. Lei, Z.M. Ren, and Q. He: ISIJ Int.,2017, vol. 57, pp. 2157-64.

[27] Y. F. Guo, Z. B. Xia, Z. Shen, Q. Li, C. X. Sun, T. X. Zheng, W. L. Ren, Z. S. Lei, Y. B. Zhong: Metall. Mater. Trans. B, 2021, vol. 52, pp. 282-91.

[28] Q. Ren, Y.X. Zhang, Y. Ren, L.F. Zhang, J.J. Wang, and Y.D. Wang: J. Mater. Sci. Technol., 2021, vol. 61, pp. 147-158.

[29] C. Shi, X. Chen, H. Guo, Z. Zhu, and H. Ren: Steel Res. Int., 2012, vol. 83, pp. 472–86.

[30] S.J. Li, G.G. Cheng, Y. Huang, W.X. Dai, and Z.Q. Miao: Metals, 2019,vol. 09, pp. 467.

[31] H. Wang, J. Li, C.B. Shi, Y.F. Qi, and Y.X. Dai: ISIJ Int., 2019, vol. 59, pp. 828-38.

[32] Z.B. Li: Electroslag Metallurgy Theory and Practice, Metallurgical Industry Press, Beijing, 2010, pp. 22–26.

Q. Wang, G.Q. Li, Z. Hfsse, B.K. Li: Appl. Therm. Eng,, 2017, vol. 114, pp. 874-86.

[34] P. G. Saffman: J. Fluid. Mech., 1965, vol. 22, pp. 385-88.

Acknowledgments

The authors gratefully acknowledged the financial support of the National Key Research and Development Program of China (2016YFB0300401, 2018YFF0109404, 2016YFB0301401), the National Natural Science Foundation of China (U1860202, U1732276, 50134010, 51704193, 51904184, 52004156), Science and Technology Commission of Shanghai Municipality (13JC14025000, 15520711000) and China Postdoctoral Science Foundation (2020M671072).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 16, 2021; accepted June 19, 2021.

Rights and permissions

About this article

Cite this article

Guo, Y., Ma, C., Xia, Z. et al. Morphology Tailoring and Enhanced Inclusion Removal of Liquid Melt Film by Regulating the Magnetic Flux Density During Magnetic Controlled ESR Process. Metall Mater Trans B 52, 3383–3392 (2021). https://doi.org/10.1007/s11663-021-02268-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02268-6