Abstract

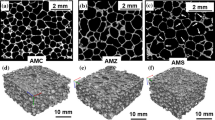

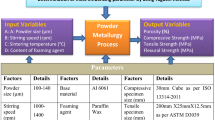

In this study, the effectiveness of three different types of Mg-based blowing agents on the structure and properties of aluminum alloy foam was compared. AlMg15Cu10 alloy foams were produced by the powder metallurgy route using pure Mg, Al50Mg50 and Al60Mg40 powders as blowing agents. Al50Mg50 and Al60Mg40 powders were synthesized by ball milling and melt milling, and were characterized by particle size analysis, XRD and SEM. Foams were characterized by using X-ray tomography, SEM and XRD. Mechanical properties were obtained through quasi-static compression tests. It was observed that the foams produced by Mg possess spherical cells whereas more polyhedral cells were obtained in the foams produced by Al50Mg50 and Al60Mg40. The finest cells were produced by Al60Mg40 powder. Variation in the cell size is attributed to the different hydrogen contents of these blowing agents. All foams resulted in a good porous structure and possess high compressive strength compared with conventional foams.

Graphical Abstract

Similar content being viewed by others

References

1. J. Banhart, Progress in Materials Science 2001, vol. 46, pp. 559-632.

2. F. García-Moreno, Materials 2016, vol. 9, pp. 85-111.

3. J. Banhart and H.W. Seeliger, Advanced Engineering Materials 2008, vol. 10, pp. 793-802.

L.J. Gibson and M.F. Ashby: Cellular solids: structure and properties. Cambridge : Cambridge University Press, 1999).

5. S. Kim and C.-W. Lee, Procedia Materials Science 2014, vol. 4, pp. 305-309.

6. M. Mukherjee, U. Ramamurty, F. Garcia-Moreno and J. Banhart, Acta Materialia 2010, vol. 58, pp. 5031-5042.

7. B. Matijasevic-Lux, J. Banhart, S.. Fiechter, O.. Görke and N. Wanderka, Acta Materialia 2006, vol. 54, pp. 1887-1900.

8. P.H. Kamm, F. García-Moreno, C. Jiménez and J. Banhart, Journal of Materials Research 2013, vol. 28, pp. 2436-2443.

9. T. Koizumi, K. Kido, K. Kita, K. Mikado, S. Gnyloskurenko and T. Nakamura, Materials Transactions 2011, vol. 52, pp. 728-733.

B. Matijasevic, O. Görke, H. Schubert and J. Banhart: Proceedings of JIMIC-4 MetFoam2005, Porous Metals and Metal Foaming Technology. 2006.

11. C. Jiménez, F. Garcia-Moreno, B. Pfretzschner, M. Klaus, M. Wollgarten, I.. Zizak, G. Schumacher, M. Tovar and J. Banhart, Acta Materialia 2011, vol. 59, pp. 6318-6330.

12. L. Helfen, T. Baumbach, H. Stanzick, J. Banhart, A. Elmoutaouakkil and P. Cloetens, Advanced Engineering Materials 2002, vol. 4, pp. 808-813.

13. M. Mukherjee, F.. Garcia-Moreno and J. Banhart, Scripta Materialia 2010, vol. 63, pp. 235-238.

14. A. Andreasen, International Journal of Hydrogen Energy 2008, vol. 33, pp. 7489-7497.

15. C. Jiménez, F. Garcia-Moreno, J. Banhart, G. Zehl, L.P. Lefebvre and D. Dunand, Porous Metals and Metallic Foams: Metfoam 2007 2008, pp. 59-62.

16. M. Mukherjee, F. Garcia-Moreno, C. Jiménez and J.. Banhart, Advanced Engineering Materials 2010, vol. 12, pp. 472-477.

17. S. Bouaricha, J.P. Dodelet, D. Guay, J. Huot, S. Boily and R. Schulz, Journal of Alloys and Compounds 2000, vol. 297, pp. 282-293.

18. E.W. Andrews, G. Gioux, P. Onck and L.J. Gibson, International Journal of Mechanical Sciences 2001, vol. 43, pp. 701-713.

19. I. Jeon and T. Asahina, Acta Materialia 2005, vol. 53, pp. 3415-3423.

20. H. Okamoto, Journal of Phase Equilibria and Diffusion 1998, vol. 19, p. 598.

A.K. Chaubey, S. Scudino, M. SamadiKhoshkhoo, K.G. Prashanth, N.K. Mukhopadhyay, B.K. Mishra and J. Eckert, J. Alloys Compd. 2014, vol. 610, pp. 456-461.

22. A.R. Cooper Jr and L.E. Eaton, Journal of the American Ceramic Society 1962, vol. 45, pp. 97-101.

23. C. Suryanarayana, Progress in Materials Science 2001, vol. 46, pp. 1-184.

24. K.A. Nazari, A. Nouri and T. Hilditch, Materials Letters 2015, vol. 140, pp. 55-58.

25. A. Azimi, A. Shokuhfar and A. Zolriasatein, Materials Science and Engineering: A 2014, vol. 595, pp. 124-130.

J. Baumeister and H. Schrader: U.S. Patent 5151246 A, 1992.

27. C. Jiménez, F. Garcia-Moreno, M. Mukherjee, O. Goerke and J.. Banhart, Scripta Materialia 2009, vol. 61, pp. 552-555.

28. J. Karch, R. Birringer and H. Gleiter, Nature 1987, vol. 330, pp. 556-558.

29. M.J. Mayo, R.W. Siegel, Y.X. Liao and W.D. Nix, Journal of Materials Research 1992, vol. 7, pp. 973-979.

30. R.N. Lumley, T.B. Sercombe and G.M. Schaffer, Metallurgical and Materials Transactions A 1999, vol. 30, pp. 457-463.

31. K. Kondoh, A. Kimura and R. Watanabe, Powder Metallurgy 2001, vol. 44, pp. 161-164.

A. Andreasen: Report No. 8755034594, Risø National Laboratory, Denmark, 2005.

33. C. Körner, M. Thies and R. F Singer, Advanced Engineering Materials 2002, vol. 4, pp. 765-769.

B. Vigeholm, K. Jensen, B. Larsen and A. SchrøderPedersen, Journal of the Less Common Metals 1987, vol. 131, pp. 133-141.

35. P. Selvam, B. Viswanathan, C.S. Swamy and V. Srinivasan, International Journal of Hydrogen Energy 1986, vol. 11, pp. 169-192.

36. P.S. Rudman, Journal of Applied Physics 1979, vol. 50, pp. 7195-7199.

W.E. Wallace, R.S. Craig, and V.U.S. Rao: Department of Chemistry, University of Pittsburgh, 1978.

38. L. Schlapbach, A. Seiler and F. Stucki, Materials Research Bulletin 1979, vol. 14, pp. 785-790.

39. L. Helfen, T. Baumbach, P.. Pernot, P.. Cloetens, H. Stanzick, K.. Schladitz and J.. Banhart, Applied Physics Letters 2005, vol. 86, p. 231907.

40. A.. Rack, H.-M. Helwig, A.. Bütow, A. Rueda, B. Matijašević-Lux, L. Helfen, J. Goebbels and J. Banhart, Acta Materialia 2009, vol. 57, pp. 4809-4821.

D.L. Weaire and S. Hutzler: The Physics of Foams. Oxford: Oxford University Press, 2001.

42. L.J. Gibson, Annual Review of Materials Science 2000, vol. 30, pp. 191-227.

43. M. Kolluri, M. Mukherjee, F.. Garcia-Moreno, J. Banhart and U. Ramamurty, Acta Materialia 2008, vol. 56, pp. 1114-1125.

44. Y. Sugimura, A.. Rabiei, A.G. Evans, A.M. Harte and N.A. Fleck, Materials Science and Engineering: A 1999, vol. 269, pp. 38-48.

T. Miyoshi, M. Itoh, T. Mukai, H. Kanahashi, H. Kohzu, S. Tanabe, and K. Higashi: Scripta Mater., 1999, vol. 41, pp. 1055–60.

46. L.J. Gibson, M.F. Ashby, J. Zhang and T.C. Triantafillou, International Journal of Mechanical Sciences 1989, vol. 31, pp. 635-663.

47. S. Lee, F. Barthelat, N. Moldovan, H. D. Espinosa and H.N.G. Wadley, International Journal of Solids and Structures 2006, vol. 43, pp. 53-73.

48. C.E. Wen, Y. Yamada, K. Shimojima, Y. Chino, H. Hosokawa and M. Mabuchi, Materials Letters 2004, vol. 58, pp. 357-360.

Acknowledgment

The authors thank the Naval Research Board of Defence Research and Development Organization, India, for funding this study through project number NRB-371/MAT/15-16.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 15, 2020. Accepted October 10, 2020.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Barode, J., Aravind, U., Bhogi, S. et al. Mg and Mg-Based Blowing Agents for Aluminum Foam. Metall Mater Trans B 52, 292–304 (2021). https://doi.org/10.1007/s11663-020-02008-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-02008-2