Abstract

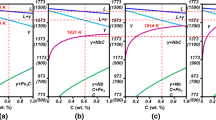

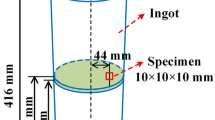

Chemical variation occurring during the solidification process can cause undesirable effects on the material property, especially for alloys with high solute content. The current study investigated the distributions of solute elements in directional solidified Fe–Mn–C–Al TWIP steels and compared the micro-segregation with various pulling rates and C contents using the phase field model and the grid analysis based on the data performed by EPMA, which could provide advice for mitigating micro-segregation in high Mn steel. The results indicated that C and Mn preferentially segregated toward the liquid phase, while Al entered the solid phase. The occurrence of solid-state diffusion was observed, which led to a homogenization effect in the solid phase during solidification. The pulling speed increase made a more severe micro-segregation because the change of pulling speeds had more effect on the SDAS than on the local solidification time; thus, the dimensionless diffusion time decreased with increasing pulling rates, representing a more serious micro-segregation. For a C content increasing from 0.06 to 0.68 wt pct, the micro-segregation level of C and Al reduced first and then increased, which was caused by the change in the solidification mode. The continuous accumulation of solute elements and the slower solute element diffusion in austenite in combination led to the presence of more severe micro-segregation in the case of one-phase solidification. Besides, a C content increase could attract Mn, resulting in more serious Mn micro-segregation.

Similar content being viewed by others

References

H Liu, J Liu, S Michelic, Wei F, C Zhuang, Z Han, S Li: Ironmak. Steelmak., 2016, vol. 43(3), pp. 171-79.

D. Senk, H. Emmerich, J. Rezende, R. Siquieri: Adv Eng Mater, 2007, vol. 9(8), pp. 695-702.

E.T. Turkdogan:Fundamentals of Steelmaking, The Institute of Materials, Cambridge, 1996, pp. 307–14.

O. Kubaschewski, C.B. Alcock, P.J. Spencer: Materials Thermochemistry, 6th ed., Pergamon Press, Tarrytown, NY, 1993, pp. 278.

Y. Shen, S. Yang, J. Liu, R. Zhang, H. Xu, Y. He (2019) Steel Res. Int. 90(5), 1800546.

J. A. Sarreal and G. J. Abbaschian: Metall. Trans. A, 1986, vol. 17A, pp. 2063–73.

J. Lacaze and G. Lesoult: Mater. Sci. Eng. A, 1993, vol. 173, pp. 119–22.

J. Lacaze and G. Lesoult: ISIJ Int., 1995, vol. 35, pp. 658–64.

M. A. Martorano and J. D. T. Capocchi: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 3137–48.

D. Mirkovic and R. Schmid-Fetzer: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 958–73.

C. Alves, J. Rezende, D. Senk: Steel Res. Int., 2016, vol. 87, pp. 1179-89.

J. Rezende, D. Senk, D. Huettenmeister, D. Senk: Steel Res. Int., 2015, vol. 86, pp. 65.

A. Kagawa, K. Iwata, A. A. Nofal,T. Okamoto: Mater. Sci. Technol., 1985, vol. 1, pp. 678–83.

P. M. N. Ocansey and D. R. Pourier: J. Mater. Sci. Eng. A, 1996, vol. A211, pp. 10–14.

A. Tu¨rkeli and D.H. Kirkwood: in Solidif. Process. 1997 Proc. 4th Decenn. Int. Conf. Solidif. Process., J. Beech and H. Jones, eds., The University of Sheffield, 1997, pp. 308–11.

H. Liu, J. Liu, B. Wu, Y. Shen, Y. He, H. Ding, X. Su. Mater. Sci. Eng. A, 2017, vol. 708, pp. 360–74.

P. Lan, H. Tang, J. Zhang: Metall. Mater. Trans. A, 2016, vol. 47(6), pp. 2964–84.

G. Krauss: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 781–92.

Y. Shen, J. Liu, S. Yang, B. Yan, Y. He, H. Liu, H. Xu. J. Cryst. Growth, 2019, vol. 511, pp. 118–26.

Z. Min, J. Shen, Z. Feng, L. Wang, L. Liu, H. Fu: Acta Metall Sin-Eng, 2010, vol. 46(12), pp. 1543–48.

M. N. Gungor: Metall. Trans. A, 1989, vol. 20A, pp. 2529–33.

D.R. Poirier. Microsegregation in Ternary Iron–Carbon–Chromium Alloys. Massachusetts Institute of Technology, 1966.

S. Kobayashi: Trans. Iron Steel Inst. Jpn, 1988, vol. 28, pp. 728–35.

S. K. Choudhary, S. Ganguly: ISIJ Int., 2007, vol. 47(12), pp. 1759–66.

T. Clyne, W. Kurz, Metall. Mater. Trans. A, 1981, vol. 12, pp. 965–71.

B. Steenken, J. Rezende, D. Senk: Mater Sci Tech, 2017, vol. 33(5), pp. 567–73.

A. Ghosh: ISIJ int., 2009, vol. 49(12), pp. 1819–27.

J. S. Kirkaldy, J. von Destinon-Forstmann, R. J. Brigham: Can. Metall. Q., 1962, vol. 1, pp. 59–81.

J. von Appen, R. Dronskowski: Steel Res. Int., 2011, vol. 82(2). pp. 101–07.

Acknowledgments

The authors gratefully acknowledge the financial support of this research provided by the National Nature Science Foundation of China (Grant No. 51574022) and China Scholarship Council (File No. 201906460091). The authors express sincere thanks to Prof. Deter Senk of the Department of Ferrous Metallurgy, RWTH Aachen University, for his kindly help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 31, 2020; accepted September 15, 2020.

Rights and permissions

About this article

Cite this article

Shen, Y., Liu, J., Xu, H. et al. Micro-segregation Study of Directional Solidified Fe–Mn–C–Al TWIP Steels. Metall Mater Trans B 51, 2963–2975 (2020). https://doi.org/10.1007/s11663-020-01982-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01982-x