Abstract

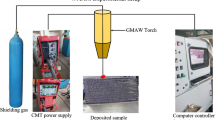

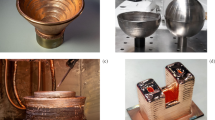

Various additive manufacturing processes are being evaluated to reduce the time and cost for fabrication of low volume, complex, and multifunctional assemblies. This study evaluated two direct energy deposition processes for the fabrication of large bi-metallic structures. The materials evaluated were Inconel 625 and copper alloy C18150, which are used in various high heat flux applications. Inconel was deposited onto the C18150 substrate using blown powder and wire-fed processes. Complete bonding was obtained in both processes and the resulting interfaces were evaluated using microscopy and indentation testing. Differences were observed in the interface region suggesting the kinetic energy of the blown powder process resulted in more residual stress at the interface, promoting recrystallization and enhanced diffusion. This created a broader interface in the blown powder specimens compared to a narrower mechanically mixed interface with the wire-fed process.

Similar content being viewed by others

References

W.E. Frazier: JMEPEG, 2014, vol. 23, pp. 1917-1928. https://doi.org/10.1007/s11665-014-0958-z.

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff and S.S. Babu: Intl. Mat. Reviews, 2016, vol. 61, no. 5, pp. 315-360. https://doi.org/10.1080/09506608.2015.1116649.

A. Bandyopadhyay and K.D. Traxel: JAM, 2018, vol. 22, pp. 758-774.

V.V. Rybin and D.L. Smith: J. Nuclear Matl., 1992, vol. 191-194, pp. 30-36.

J.M. Kazaroff and G.A. Repas: NASA Technical Paper No. 2694, 1987.

P.R. Gradl: 2016, AIAA Conf. Proc. No. 2016–4771. https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20160009709.pdf. Accessed 22 March 2017.

A. Bandyopadhyay and B. Heer: Mat. Sci. & Engr. Review, 2018, vol. 129, pp. 1-16.

B. Onuike, B. Heer and A. Bandyopadhyay: JAM, 2018, vol. 21, pp. 133-140.

NASA-MSFC Press Release, https://www.nasa.gov/centers/marshall/news/news/releases/2017/nasa-tests-first-3-d-printed-rocket-engine-part-made-with-two-different-alloys.html. Accessed 19 September 2017.

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal and P. Colegrove: Mater. Sci. Tech., 2016, vol. 32, no. 7, pp. 641-647.

D.C. Hofmann, J. Kolodziejska, S. Roberts, R. Otis, R.P. Dillon, J.O. Suh, Z.K. Liu and J.P. Borgonia: J. Mater. Res., 2014, vol. 29, no. 17, pp. 1899-1910.

K. Shah, I. Ul Haq, A. Khan, S.A. Shah, M. Khan and A.J Pinkerton: Mater. Des., 2014, vol. 54, pp. 531-538.

H. Sahasrabudhe, R. Harrison, C. Carpenter and A. Bandyopadhyay: JAM, 2015, vol. 5, pp. 1-8.

A. Hinojos, J. Mireles, A. Reichardt, P. Frigola, P. Hosemann, L.E. Murr and R.B. Wicker: Mat. & Design, 2016, vol. 94, pp. 17-27.

B.E. Carroll, R.A. Otis, J.P. Borgonia, J-O Suh, R.P. Dillon, A.A. Shapiro, D.C. Hofmann, Z-K Liu and A.M. Beese: Acta Mater., 2016, vol. 108, pp. 46-54.

A. Reichardt, R.P. Dillon, J.P. Borgonia, A.A. Shapiro, B.W. McEnerney, T. Momose and P. Hosemann: Mat. & Design, 2016, vol. 104, pp. 404-413.

W. Li, S. Karnati, C. Kriewall, F. Liou, J. Newkirk, K.M. Brown-Taminger and W.J. Seufzer: JAM, 2017, vol. 14, pp. 95-104.

Phase Diagrams. European Space Agency. http://www.spaceflight.esa.int/impress/text/education/Solidification/Phase_Diagrams.html#Top. Accessed 5 November 2016.

Haynes International Brochure H-3073D, http://mail.haynesintl.com/pdf/h3073.pdf. Accessed August 2018.

https://alloys.copper.org/alloy/C18150. Accessed 5 September 2017.

Special Metals MONEL® Alloy 400. MatWeb: Material Property Data. http://www.matweb.com/search/datasheet.aspx?matguid=1364d8231703476b8c466cdd07be71b7. Accessed 16 October 2017.

H. L. Eiselstein and D. J. Tillack: TMS pub., 1991, https://doi.org/10.7449/1991/superalloys 1991, pp. 1–14.

A.K. Jena and M.C. Chaturvedi: J. Mat. Sci., 1984, vol. 19, pp. 3121-3139.

American Welding Society C3 Committee on Brazing and Soldering: Brazing Handbook, 5th ed., American Welding Society, Miami, FL, 2007, pp. 169–78.

S. Yin, P. Cavaliere, B. Aldwell, R. Jenkins, H. Liao, W. Li and R. Lupoi: JAM, 2018, vol. 21, pp. 628-650.

S.M. Schwarz, B.W. Kempshall and L.A. Giannuzzi: Acta Mater., 2002, Vol. 51, no. 10, pp. 2765-2776. https://doi.org/10.1016/s1359-6454(03)00082-x.

H.L. Wang, Z.B. Wang and K. Lu: Acta Mater., 2011, vol. 59, pp. 1818-1828.

S.M. Eich, M. Kasprzak, A. Gusak and G. Schmitz: Acta Mater., 2012, vol. 60, pp. 3469-3479.

I. Kaur, Y. Mishin and W. Gust: Fundamentals of grain and interphase boundary diffusion, 3rd ed., Wiley publishers, New York, 1995, pp. 343-349.

B. Wierzba and W. Skibinski: J. Alloys & Comp., 2016, vol. 687, pp. 104-108.

Acknowledgments

This work was supported in part from NASA STTR Phase I with Keystone Synergistic Enterprises, Inc. Grant No. NNX16CM41P, “Advancing Metal Direct Digital Manufacturing (MDDM) Processes for Reduced Cost Fabrication of Bi-Metallic Cooled Rocket Engines,” and Aetos Systems Grant No. NNM14AA15C/Subcontract No. 2019. A52, “Additive/subtractive manufacturing of combustion devices.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 14, 2018.

Rights and permissions

About this article

Cite this article

Anderson, R., Terrell, J., Schneider, J. et al. Characteristics of Bi-metallic Interfaces Formed During Direct Energy Deposition Additive Manufacturing Processing. Metall Mater Trans B 50, 1921–1930 (2019). https://doi.org/10.1007/s11663-019-01612-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01612-1