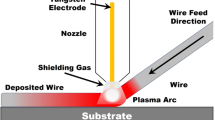

Metal additive manufacturing is one of the new industrial technologies for fast prototyping of the metal components with a complex internal architecture, gradient composition, or functionally gradient properties. Intermetallic alloys are hard-to-work materials, their conventional production and post-production processing are very complex and expensive routine. New production methods, such as an additive manufacturing, are promising for fast and relatively simple fabrication of the intermetallic billets with the desired phase composition and architecture. Multiple-wire electron-beam additive manufacturing is among them. In this work, we fabricated a bimetallic material (plain wall) using the industrial NiCr and Al wires. For the as-built state, we provided the elemental and phase analyses of the NiCr lower part and Al upper part of the billet with the focus on the intermediate gradient layers between two materials. During the additive manufacturing of the NiCr part of the billet, the Ni-based fcc solid solution forms. Scanning electron microscopical analysis, X-ray diffraction analysis, and energy dispersive spectroscopy confirm the formation of NiAl and Ni3Al intermetallic phases in the transition zone under electron beam additive manufacturing of the bimetallic material. This intermetallic zone has high microhardness (up to 10 GPa). The Al3Ni intermetallic phase has been found in the Al-based part of the billet, but the microhardness of the composite material (Al + Al3Ni) is just a bit higher than that in the upper Al-based part of the billet.

Similar content being viewed by others

References

W. E. Frazier, J. Mater. Eng. Perform., 23, 1917–1928 (2014).

C. R. Cunningham, J. M. Flynn, A. Shokrani, et al., Addit. Manuf., 22, 672–686 (2018).

S. Tammas-Williams, H. Zhao, F. Léonard, et al., Mater. Charact., 102, 47–61 (2015).

J. G. Callanan, A. N. Black, S.K. Lawrence, et al., Acta Mater., 246, 118636 (2023).

B. Song, S. Dong, P. Coddet, et al., Mater. Des., 53, 1–7 (2014).

D. Ding, Z. Pan, D. Cuiuri, and H. Li, Int. J. Adv. Manuf. Technol., 81, 1–4 (2015).

B. Utela, D. Storti, R. Anderson, and M. Ganter, J. Manuf. Process., 10, No.2, 96–104 (2008).

D. Wu, J. Shi, F. Niu, et al., J. Eur. Ceram. Soc., 42 (2022); https://doi.org/10.1016/j.jeurceramsoc.2022.12.068.

D. Bourell, J.P. Kruth, M. Leu, et al., CIRP Ann. Manuf. Technol., 66, 659–681 (2017).

K. Osipovich, K. Kalashnikov, A. Chumaevskii, et al., Metals, 13 (2), 279 (2023).

T. DebRoy, H. L. Wei, J. S. Zuback, et al., Prog. Mater. Sci., 92,112–224 (2018).

S. Ma, Y. Li, W. Kan, et al., J. Alloys Compd., 924, 166395 (2022).

S. Astafurov, E. Astafurova, K. Reunova, et al., Mater. Sci. Eng. A, 826 (2), 141951 (2021).

X. Zhang, H. Shi, X. Wang, et al., J. Alloys Compd., 938, 168567 (2023).

N. S. Stoloff, C. T. Liu, and S. C. Deevi, Intermetallics, 8, Nos. 9–11, 1313–1320 (2000).

J. J. S. Dilip, H. Miyaniji, A. Lassel, et al., Defence Technol., 13 (2), 72–76 (2017).

L. Wang, Y. Zhang, X. Hua, et al., Mater. Sci. Eng. A, 812 (10–11), 141056 (2021).

Y. Meng, J. Li, M. Gao, and X. Zeng, J. Manuf. Process. A, 68, 932–939 (2021).

P. Fernandez-Zelaia, M. M. Kirka, A. M. Rossy, et al., Acta Mater., 216 (5), 117133 (2021).

Y. Yu, J. Zhou, J. Chen, et al., Wear, 274, 298–305 (2012).

C. A. Barrett and C. E. Lowell, Oxid. Met., 11, 199–223 (1977).

K. M. Jaansalu, Phase Diagram Modelling: Nickel-Aluminum-Chromium System. Technical Memorandum, Air Vehicle Research Detachment, DCIEM, National Defence Headquarters, Ottawa (1998).

A. V. Kamashev, A. S. Panin, A. L. Petrov, and I. V. Shishkovskii, Appl. Phys. Lett., 27, No. 6, 408–499 (2001).

I. V. Shishkovsky, N. Kakovkina, and F. Missemer, Lasers Eng., 33 (1–3), 1–15 (2016).

S. Sampath, V. P. Ravi, and S. Sundararajan, Crystals, 13 (3), 435 (2023).

E. A. Kolubaev, V. E. Rubtsov, A. V. Chumaevsky, and E. G. Astafurova, Phys. Mesomech., 25, 479–491 (2022).

R. Yamanoglu, E. Karakulak, M. Zeren, and F. G. Koç, Int. J. Cast Met. Res., 26 (5), 289–295 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reunova, K.A., Zagibalova, E.A., Astapov, D.O. et al. Microstructure, Phase Composition, and Microhardness of the NiCr/Al Gradient Material Produced by Wire-Feed Electron-Beam Additive Manufacturing. Russ Phys J 66, 341–349 (2023). https://doi.org/10.1007/s11182-023-02945-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02945-w