Abstract

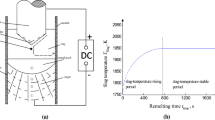

Experimental and theoretical studies have been carried out to investigate the effects of the slag on desulfurization during the electroslag remelting (ESR) process with a focus of developing a mass transfer model to understand the mechanism of desulfurization. Stainless steel 1Cr21Ni5Ti was used as the electrode and remelted with two different kinds of slags using a 50-kg ESR furnace. The contents of sulfur along the axial direction of product ingots were analyzed. It was found that the sulfur content of 350 ppm in the electrode is reduced to 71 to 95 ppm in the ingot by remelting with the slag containing 5 wt pct of CaO, and lowered more to 47 to 59 ppm with another slag having 20 wt pct CaO. On the basis of the penetration and film theories, the theoretical model developed in this work well elucidates the kinetics of desulfurization revealing the mechanism of sulfur transfer during the ESR process. The calculation results obtained from the model agree well with the experimental results. The model indicates that when sulfur content in electrode is given, there is a corresponding minimum value of sulfur content in the ingot due to the kinetics limit. This lowest sulfur content cannot be further reduced even with increasing L S (sulfur distribution coefficient between metal and slag phases) or decreasing sulfur content in the slag. Constant addition of extra amount of CaO to the molten slag with the increase of sulfur content in the slag during the remelting process can improve the macrosegregation of sulfur distributed along the axial direction of ESR ingots. Since the rate-determining steps of the sulfur mass transfer lie in the metal phase, adding calcium as deoxidizer can change mass transfer of sulfur and thus promote desulfurization further during the ESR process.

Similar content being viewed by others

References

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Ryberon, V. Schmitt, S. Hans, and H. Poisson: Metall. Mater. Trans. B, 2009, vol.40B, no.3, pp. 271-280.

S.K. Matity, N.B. Ballal, G. Goldhahn, and R. Kwaalla: ISIJ Int., 2009, vol.49, no.6, pp. 902-910.

C.B. Shi, X.C. Chen, H.J. Guo, Z.J. Zhu, and H. Ren: Steel Research Int., 2012, vol.83, no.5, pp. 472-486.

Y.W. Dong, Z.H. Jiang, Y.L. Cao, A. Yu, and D. Hou: Metall. Mater. Trans. B, 2014, vol.45B, no.4, pp. 1315-1324.

X.Z. Zhang: Fundamentals of transport phenomena and reaction engineering in process metallurgy, Metallurgical Industry Press, Beijing, China, 2010, pp. 391-393.

M.E. Fraser, and A. Mitchell: Ironmaking Steelmaking, 1976, vol.3, no.5, pp. 279-287.

D. Hou, Z.H. Jiang, Y.W. Dong, Y.L. Cao, H.B. Cao and W. Gong: Ironmaking & Steelmaking, 2016, vol.43, no.7, pp.517-525.

X.M. Yang, J.S. Jiao, R.C. Ding, C.B. Shi, and H.J. Guo: ISIJ Int., 2009, vol.49, no.12, pp. 1828-1837.

X.M. Yang, C.B. Shi, M. Zhang, and G.M. Chai: Metall. Mater. Trans. B, 2011, vol.42B, no.12, pp. 1150-1180.

X.M. Yang, C.B. Shi, M. Zhang, J.P. Duan, and J. Zhang: Metall. Mater. Trans. B, 2011, vol.42B, no.10, pp. 951-2011.

X.M. Yang, J.P. Duan, C.B. Shi, M. Zhang, Y.L. Zhang, and J.C. Wang: Metall. Mater. Trans. B, 2011, vol.42B, no.8, pp.738-770.

Z.H. Jiang, D. Hou, Y.W. Dong, Y.L. Cao, H.B. Cao, and W. Gong: Metall. Mater. Trans. B, 2016, vol.47B, no.2, pp. 1465-1474.

C.B. Shi, X.M. Yang, J.S. Jiao, C. Li, and H.J. Guo: ISIJ Int., 2010, vol.50, no.10, pp. 1362-1372.

J.H. Park, S.B. Lee, D.S. Kim and J.J. Pak: ISIJ Int., 2009, vol.49, no.3, pp.337-342.

The Japan Society for the Promotion of Science: The 19th Committee on Steelmaking: Steelmaking Data Sourcebook, Gordon and Breach Science Publishers, New York, NY, 1988.

A. Karasev, H. Suito: Metall. Mater. Trans. B, 1999, vol.30, no.4, 257-249.

J.H. Wei, and A. Mitchell: Acta Metallurgica Sinica, 1984, vol.20, no.5, pp. 261-279.

C.J. Xiang. Chart data manual for steelmaking, Metallurgical Industry Press, Beijing, China, 1984, pp. 662.

A. Mitchell: Doctor’s Thesis, The University of British Columbia, 1974, pp.103.

M. Choudhary and J. Szekely: Metall. Mater. Trans. B, 1980, vol.11, no.9, pp.439-452.

Q. Wang, Z. He, B.K. Li and F. Tsukihashi: Metall. Mater. Trans. B, 2014, vol.45, no.12, pp.2014-2425.

G. Okuyama, K. Yamaguchi, S. Takeuchi, and K. Sorimachi: ISIJ Int., 2000, vol.40, no.2, pp. 121-128.

X.C. Chen, F. Wang, C.B. Shi, H. Ren, and D. Feng: Journal of Iron and Steel Research, 2012, vol.24, no.12, pp. 11-16.

Acknowledgments

This project was supported by the National Nature Science Foundation of China with the Grant No. 51274266 and supported by Joint Research Fund of National Nature Science Foundation of China and Baosteel Group Corporation with the Grant No. U1360103 and No. U1560203. Also, this project was supported by Fundamental Research Funds for Central University of China with the Grant No. 150202003.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 27, 2016.

Rights and permissions

About this article

Cite this article

Hou, D., Jiang, ZH., Dong, YW. et al. Mass Transfer Model of Desulfurization in the Electroslag Remelting Process. Metall Mater Trans B 48, 1885–1897 (2017). https://doi.org/10.1007/s11663-017-0921-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0921-0