Abstract

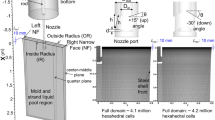

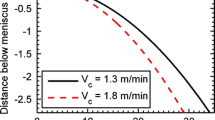

Transient mold flow could produce undesirable surface instabilities and slag entrainments, leading to the formation of defects during continuous slab casting of steel. In this work, two Large Eddy Simulations coupled with Discrete Phase Model are run, with and without MagnetoHydroDynamic model, to gain new insights into the surface variations of molten steel-argon gas flow with anisotropic turbulence in the slide-gate nozzle and the mold, with and without double-ruler Electro-Magnetic Braking (EMBr). The model calculations are validated with plant measurements, and applied to investigate the flow variations related to the slide gate on nozzle swirl, jet wobbling, and surface flow variations by quantifying the variations of velocity, horizontal angle, and vertical angle of the transient flow. Transient flow in the slide-gate nozzle bottom is almost always swirling, alternating chaotically between clockwise and counter-clockwise rotation. The clockwise swirl, caused by stronger flow down the same side of the nozzle as the open area near the Outside Radius side of the slide-gate middle plate, produces faster jet flow and higher velocity flow across the top surface of the mold. Counter-clockwise swirl produces slower jet and surface flow, but with more variations. The double-ruler EMBr decreases the asymmetry and duration of velocity variations during nozzle swirl flipping, resulting in less flow variations in the jet and across the surface in the mold.

Similar content being viewed by others

References

C. Ojeda, B.G. Thomas, J. Barco and J.L. Arana: Proc. of AISTech 2007, Assoc. Iron Steel Technology, Warrendale, PA, 2007, pp. 269–83

J. Sengupta, C. Ojeda and B. G. Thomas: Int. J. Cast Metal. Res., 2009, vol. 22, pp. 8-14

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno: ISIJ Int., 2000, vol. 40, pp. 685-691

L.C. Hibbeler, R. Liu, and B.G. Thomas: Proc. of 7th ECCC, Steel Institute VDEh, Germany, 2011, pp. 1–10

R. Hagemann, R. Schwarze, H.P. Heller, and P.R. Scheller: Metall. Mater. Trans B, 2013, vol. 44B, pp. 80-90

S-M. Cho, G-G. Lee, S.-H. Kim, R. Chaudhary, O.-D. Kwon, and B. Thomas: Proc. of TMS 2010, TMS, Warrendale, PA, USA, 2010, pp. 71–77

S-M. Cho, S-H. Kim, R. Chaudhary, B. G. Thomas, H-J. Shin, W-R. Choi, S-K. Kim: Iron and Steel Technology, 2012, vol.9, pp. 85-95

H. Bai and B. G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269-284

T. Shi: Master degree thesis, University of Illinois at Urbana-Champaign, 2001.

H. Bai and B. G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269-284

Y. Miki and S. Takeuchi: ISIJ Int., 2003, vol.43, pp. 1548-1555

Z-Q. Liu, B-K. Li, M-F. Jiang, and F. Tsukihashi: ISIJ Int, 2013, vol. 53, pp. 484-492

K. Takatani, K. Nakai, T. Watanabe, and H. Nakajima: ISIJ Int, 1989, vol. 29, pp. 1063-1068

H. Harada, T. Toh, T. Ishii, K. Kaneko, and E. Takeuchi: ISIJ Int, 2001, vol. 41, pp. 1236-1244

Z-D. Qian and Y-L. Wu: ISIJ Int, 2004, vol. 44, pp. 100-107

K. Cukierski and B. G. Thomas: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 94-107

K. Timmel, S. Eckert, G. Gerbeth, F. Stefani, and T. Wondrak: ISIJ Int., 2010, vol. 50, pp. 1134-1141

K. Timmel, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 68-80

X. Miao, K. Timmel, D. Lucas, Z. Ren, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 954-972

R. Chaudhary, B. G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 532-553

R. Singh, B.G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1201 – 1221

R. Singh, B.G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1098 - 1115

B. Li, T. Okane, and T. Umeda: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1491-1503

B. Li, T. Okane, and T. Umeda: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 1053-1066

Y. Wang and L. Zhang: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1319-1351

H. Yu and M. Zhu: ISIJ Int., 2008, vol. 48, pp. 584-591

B. Li and F. Tsukihashi: ISIJ Int, 2003, vol. 43, pp. 923-931

K. Moon, H. Shin, B. Kim, J. Chung, Y. Hwang, and J. Yoon: ISIJ Int, 1996, vol. 36, S201-203

Y. Hwang, P. Cha, H. Nam, K. Moon, and J. Yoon: ISIJ Int, 1997, vol. 37, pp. 659-667

S-M. Cho, H-J. Lee, S-H. Kim, R. Chaudhary, B. G. Thomas, D-H. Lee, Y-J. Kim, W-R. Choi, S-K. Kim, and H-S. Kim: Proc. Of. TMS 2011, TMS, Warrendale, PA, 2011, pp. 59–66

S-M. Cho, S-H. Kim, B. G. Thomas: ISIJ Int, 2014, vol. 54, pp. 855-864

S-M. Cho, S-H. Kim, B. G. Thomas: ISIJ Int, 2014, vol. 54, pp. 845-854

ANSYS FLUENT 14.5-Theory Guide, ANSYS. Inc., Canonsburg, PA, USA, 2012

Q. Yuan: Ph. D. Thesis, University of Illinois at Urbana-Champaign, 2004.

Q. Yuan, B.G. Thomas, and S.P. Vanka, Metall. Mater. Trans. B, 2004, vol. 35B, pp. 685-702

R. Liu: Ph. D. Thesis, University of Illinois at Urbana-Champaign, 2015

F. Nicoud and F. Ducros: Flow, Turb. Comb., 1999, vol. 63(3), pp. 183–200

ANSYS FLUENT 14.5-Magnetohydrodynamics (MHD) Module Manual, ANSYS. Inc., Canonburg, PA, USA, 2012

H. Bai and B. G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 1143-1159

G.-G. Lee, B. G. Thomas, and S-H Kim: Met., Mater. Int., 2010, vol. 16, pp. 501

D. E. Hershey, B. G. Thomas, and F. M. Najjar: Int. J. Numer. Metho. Fluids, 1993, vol. 17, pp. 23-47

M. Schmidit and M. Byrne: Bethlehem Steel, Sparrows Point, Baltimore, private communication, 1992.

D. Gupta and A.K. Lahiri: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 757-764

K. Jin, S. P. Vanka, B. G. Thomas, and X. M. Ruan: Proc. Of. TMS 2016, TMS, Nashville, 2016, pp. 159–66

Acknowledgments

The authors thank POSCO for their assistance in collecting plant data and financial support (Grant No. 4.0004977.01), and Mr. Yong-Jin Kim, POSCO for help with the plant measurements. Support from the National Science Foundation (Grant No. CMMI 11-30882) and the Continuous Casting Consortium, University of Illinois at Urbana-Champaign, USA is gratefully acknowledged. This research is also part of the Blue Waters sustained petascale computing project at the National Center for Supercomputing Applications at the University of Illinois, which is supported by the National Science Foundation (Awards OCI-0725070 and ACI-1238993) and the State of Illinois.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 20, 2016.

Rights and permissions

About this article

Cite this article

Cho, SM., Thomas, B.G. & Kim, SH. Transient Two-Phase Flow in Slide-Gate Nozzle and Mold of Continuous Steel Slab Casting with and without Double-Ruler Electro-Magnetic Braking. Metall Mater Trans B 47, 3080–3098 (2016). https://doi.org/10.1007/s11663-016-0752-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0752-4