Abstract

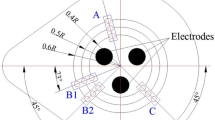

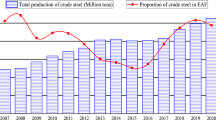

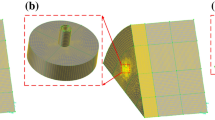

Bottom-blowing technology is widely adopted in electric arc furnace (EAF) steelmaking to promote the molten bath fluid flow, accelerate the metallurgical reaction, and improve the quality of molten steel. In this study, a water model experiment and a computational fluid dynamics model were established to investigate the effects of bottom-blowing gas flow rate on the fluid flow characteristics in the EAF molten bath. The results show that the interaction among the bottom-blowing gas streams influences the molten bath flow field, and increasing the bottom-blowing gas flow rate can accelerate the fluid flow and decrease the volume of the dead zone. Based on industrial application research, the physical and chemical properties of the molten bath with bottom-blowing were analyzed. Compared with traditional melting conditions without bottom-blowing, bottom-blowing technology demonstrates obvious advantages in promoting the heat transfer and metallurgical reactions in the molten bath. With the bottom-blowing arrangement, the dephosphorization and decarburization rates are accelerated, the contents of FeO and T. Fe in endpoint slag are decreased, and the endpoint carbon-oxygen equilibrium of molten steel is improved.

Similar content being viewed by others

REFERENCES

C. W. Du, M. Y. Zhu, L. N. Sun, S. Z. Shi: Developments in Chemical Engineering and Mineral Processing, 2006, vol. 14, pp. 353-62.

B. Lee and I. Sohn: JOM, 2014, vol. 66, no. 9, pp. 1581-1594.

H.D. Goodfellow, P. and Marcello: MPT International, 2006, vol. 29, no. 6, pp. 24-30.

L. F. Li, M. F. Jiang and Z. Y. Duan: Steelmaking, 1996, vol.12, no. 2, pp. 49-52.

L. F. Li, C. J. Jin, M. F. Jiang and W. Z. Wang: Iron & Steel, 1997, vol.32, no.6, pp. 617-619.

F. H. Liu, R. Zhu, K. Dong, X. Bao, S. L. Fan: ISIJ Int., 2015, vol. 55, no. 11, pp. 2365-2373.

B. K. Li: ISIJ Int., 2009, vol. 40, no.9, pp. 863-869.

P. He: Journal of Iron and Steel Research, 1995, vol.7, no. 3, pp. 16-21.

G. Cafeery, D. Warnica, N. Molloy and M. Lee: Int Conf on CFD in Minaral & Metal Processing and Power Generation, CSIRO, 1977, pp. 87–100.

L. Gu and G. A. Irons: Iron & Steelmaker, 2001, vol. 28, no.1, pp. 57-68.

M. Ramirez, J. Alexis, G. Trapaga, P. Jonsson and J. Mckelliget: ISIJ Int., 2001, vol. 41, no. 10, pp. 1146-1155.

C. T. Schade and R. Schmitt: Iron & Steelmaker, 1991, vol.18, pp. 23-28.

Cipolla J., Chan A. H., Pawliska V.: Iron & Steelmaker, 1991, vol. 18, pp. 27-33.

A. Lazcano, G. Vargaz and E. Reja: Iron & Steelmaker, 1990, vol. 17, no.1, pp. 58-67.

K. Dong, R. Zhu, W. J. Liu: Advanced Materials Research, 2011, vol. 36, pp. 639-643.

C. W. Hirt and B. D. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201-205.

Q. Li, M. Li, S. Kuang and Z. Zou: Metall. Trans. B, 2015, vol. 46B, pp. 1494-1509.

B. E. Launder and D. B. Spalding: Lectures in Mathematical Model of Turbulence, Academic Press, London, 1972, p. 124.

M. Lv, R. Zhu, Y. Guo and Y. Wang: Metall. Trans. B, 2013, vol. 44, pp. 1560-1571.

F. H. Liu, R. Zhu, Q. Wang and R. G. Bai: ISIJ Int., 2015, vol. 55, no. 8, pp. 1633-1641.

M. Y. Zhu, T. Inomoto, I. Sawada and T. C. Hsiao: ISIJ Int., 1995, vol. 35, no. 5, pp. 472-479.

Vikas Singh, Jyoti Kumar, C. Bhanu, S. K. Ajmani and S. K. Dash: ISIJ Int., 2007, vol. 47, no. 11, pp. 1605-1612.

X. B. Zhou, M. Ersson, L. C. Zhong, J. K. Yu and P. Jönsson: Steel Research Int., 2014, vol. 85, no. 2, pp. 273-281.

M. J. Luomala, M. J. Fabritius and J. J. Härkki: ISIJ Int., 2004, vol. 44, no. 5, pp. 809-816.

M. J. Luomala, T. M. J. Fabritius, E. O. Virtanen, T. P. Siivola and J. J. Harkki: ISIJ Int., 2002, vol. 42, no. 9, pp. 944-949.

J.K. Brimacombe, A.A. Bustos, D. Jorgensen and G.G. Richards: Physical Chemistry of Extractive Metallurgy: Proceedings of an international symposium, Metall. Society/AIME, Warrendale, PA, 1985. p. 327.

M. Hiroyuki, H. Tasuku, M. Zhong, X. Gao, X. Yang and T. Fumitaka: JOM, 2014, vol. 66, no. 9, pp. 1572-1580.

J. P. Duan, Y. L. Zhang and X. M. Yang: International Journal of Minerals, Metallurgy and Materials, 2009, vol. 16, no. 4, pp. 375-382.

S. H. Choi, B. J. Min, Y. G. Kim, J. Y. Chung and K. K. Lee, SEAISI Quarterly, 1995, vol. 24, no. 1, pp. 29-33.

C .L. He, R. Zhu, K. Dong, Y. Q. Qiu, K. M. Sun and G. L. Jiang: Ironmaking and Steelmaking, 2011, vol. 38, no. 4, pp. 291-296.

Acknowledgments

The authors would like to express their thanks for the support by the National Nature Science Foundation of China (Nos. 51474024 and 51334001) and the National Key Technology R&D Program of the 12th Five-Year Plan (12FYP 2015BAF03B01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 16, 2016.

Rights and permissions

About this article

Cite this article

WEI, G., ZHU, R., DONG, K. et al. Research and Analysis on the Physical and Chemical Properties of Molten Bath with Bottom-Blowing in EAF Steelmaking Process. Metall Mater Trans B 47, 3066–3079 (2016). https://doi.org/10.1007/s11663-016-0737-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0737-3