Abstract

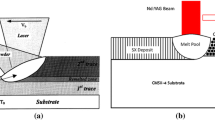

Part I [Metall. Mater. Trans. B, 2014, DOI:10.1007/s11663-014-0117-9] presented a comprehensive thermal, fluid flow, and solidification model that can predict the temperature distribution and flow characteristics for the processing of CMSX-4 alloy powder through scanning laser epitaxy (SLE). SLE is an additive manufacturing technology aimed at the creation of equiaxed, directionally solidified and single-crystal (SX) deposits of nickel-based superalloys using a fast-scanning laser beam. Part II here further explores the Marangoni convection-based model to predict the solidification microstructure as a function of the conditions at the trailing edge of the melt pool formed during the SLE process. Empirical values for several microstructural characteristics such as the primary dendrite arm spacing (PDAS), the columnar-to-equiaxed transition (CET) criterion and the oriented-to-misoriented transition (OMT) criterion are obtained. Optical microscopy provides visual information on the various microstructural characteristics of the deposited material such as melt depth, CET location, OMT location, PDAS, etc. A quantitative and consistent investigation of this complex set of characteristics is both challenging and unprecedented. A customized image-analysis technique based on active contouring is developed to automatically extract these data from experimental micrographs. Quantitative metallography verifies that even for the raster scan pattern in SLE and the corresponding line heat source assumption, the PDAS follows the growth relation w ~G −0.5 V −0.25 (w = PDAS, G = temperature gradient and V = solidification velocity) developed for marginal stability under constrained growth. Models for the CET and OMT are experimentally validated, thereby providing powerful predictive capabilities for controlling the microstructure of SX alloys processed through SLE.

Similar content being viewed by others

Abbreviations

- SLE:

-

Scanning laser epitaxy

- PDAS/w:

-

Primary dendrite arm spacing

- CET:

-

Columnar-to-equiaxed transition

- OMT:

-

Oriented-to-misoriented transition

- SX:

-

Single-crystal

- G :

-

Temperature gradient

- V :

-

Solidification velocity

- E snake :

-

Total energy of the snake line

- E int :

-

Internal force of the spline

- E image :

-

Image force

- E con :

-

Constraints force

- E line :

-

Intensity of the filtered Canny output

- E term :

-

Termination force

- E edge :

-

edge force

- ei :

-

Coefficient of the force terms

- I:

-

Image intensity

- S:

-

Displacement

- N 0 :

-

Nucleation density

- \( \Delta T_{\text{tip}}^{{}} \) :

-

Tip undercooling

- \( \Delta T_{n}^{{}} \) :

-

Nucleation undercooling

- x,y :

-

Co-ordinates

- D:

-

Diffusion coefficient in the liquid

- Γ:

-

Gibbs–Thomson coefficient

- ΔT 0 :

-

Liquidus-solidus range in initial alloy

- K:

-

Equilibrium distribution coefficient

- [ijk]:

-

Direction

- C:

-

Polynomial fit constant

- a, n :

-

Material constant

- Φ :

-

Equiaxed fraction

- G hkl :

-

Temperature gradient in [hkl] direction

References

R. Acharya, R. Bansal, J.J. Gambone, and S. Das: Metall. Mater. Trans. B, 2014, DOI:10.1007/s11663-014-0117-9.

J. Canny: IEEE Trans. Pattern Anal. Mach. Intell., 1986, pp. 679–98.

D. Marr and E. Hildreth: Proc. R. Soc. Lond. Ser. B. Biol. Sci. 1980, vol. 207, pp. 187–217.

Andrew Blake, Michael Isard and David Reynard: Artificial Intelligence 1995, vol. 78, pp. 179-212.

Michael Kass, Andrew Witkin and Demetri Terzopoulos: International journal of computer vision 1988, vol. 1, pp. 321-31.

S. Kichenassamy, A. Kumar, P. Olver, A. Tannenbaum, and A. Yezzi: in Computer Vision, 1995. Proc. Conf. Fifth Int., IEEE, 1995, pp 810–15.

W Kurz and DJ Fisher: Fundamentals of Solidification. 3rd ed., Trans Tech Publications, Aedermannsdorf, Switzerland, 1992.

W Kurz and DJ Fisher: Acta Metallurgica 1981, vol. 29, pp. 11-20.

JS Langer and J Müller-Krumbhaar: Journal of Crystal Growth 1977, vol. 42, pp. 11-14.

Pollock TM, Tin S (2006) Journal of propulsion and power 22:361-74.

AJ Elliott and TM Pollock: Metallurgical and Materials Transactions A 2007, vol. 38, pp. 871-82.

M. Gaumann: PhD Thesis, EPFL Lausanne, Lausanne, 1999.

M. Gäumann, C. Bezençon, P. Canalis and W. Kurz: Acta Materialia 2001, vol. 49, pp. 1051-62.

JD Hunt: Materials Science and Engineering 1984, vol. 65, pp. 75-83.

M Rappaz, SA David, JM Vitek and LA Boatner: Metallurgical Transactions A 1989, vol. 20, pp. 1125-38.

M Gäumann, R Trivedi and W Kurz: Materials Science and Engineering: A 1997, vol. 226, pp. 763-69.

M. Rappaz and Ch A. Gandin: Acta Metall. et Mater. 1993, vol. 41, pp. 345–60.

JM Vitek: Acta Materialia 2005, vol. 53, pp. 53-67.

T. D. Anderson, J. N. DuPont and T. DebRoy: Acta Materialia 2010, vol. 58, pp. 1441-1454.

S. Mokadem, C. Bezençon, A. Hauert, A. Jacot and W. Kurz: Metallurgical and Materials Transactions A 2007, vol. 38, pp. 1500-10.

Weiping Liu and J. N. DuPont: Acta Materialia 2005, vol. 53, pp. 1545-58.

J Safari and S Nategh: Journal of materials processing technology 2006, vol. 176, pp. 240-50.

C. Flanagan: The Bresenham line-drawing algorithm (2009), http://www.cs.helsinki.fi/group/goa/mallinnus/lines/bresenh.html, 2012.

Michael LV Pitteway: The Computer Journal 1967, vol. 10, pp. 282-89.

W Wang, PD Lee and M McLean: Acta Materialia 2003, vol. 51, pp. 2971-87.

R. Trivedi: Metallurgical Transactions A 1984, vol. 15, pp. 977-982.

H. Esaka, W. Kurz, and R. Trivedi: in Solidification Processing, The Institute of Metals, London, 1988, pp 168–71.

C. L. Chan, J. Mazumder and M. M. Chen: Journal of Applied Physics 1988, vol. 64, p. 6166.

L. X. Yang, X. F. Peng and B. X. Wang: International Journal of Heat and Mass Transfer 2001, vol. 44, pp. 4465-73.

W. Liu and J. N. DuPont: Acta Mater. 2004, vol. 52, pp. 4833–47.

M Rappaz, SA David, JM Vitek and LA Boatner: Metallurgical Transactions A 1990, vol. 21, pp. 1767-82.

Acknowledgements

The authors gratefully acknowledge the financial support for this work by the Office of Naval Research through grant N00014-11-1-0670 as part of the Cyber enabled Manufacturing Systems (CeMS) program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 21, 2014.

Rights and permissions

About this article

Cite this article

Acharya, R., Bansal, R., Gambone, J.J. et al. A Microstructure Evolution Model for the Processing of Single-Crystal Alloy CMSX-4 Through Scanning Laser Epitaxy for Turbine Engine Hot-Section Component Repair (Part II). Metall Mater Trans B 45, 2279–2290 (2014). https://doi.org/10.1007/s11663-014-0183-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0183-z