Abstract

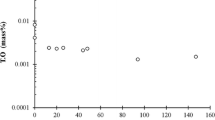

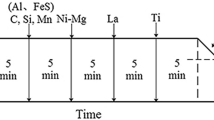

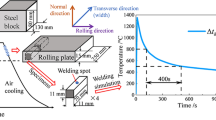

By sampling the important nodes in the smelting process of oxide metallurgical steel, the evolution of number density, size and type of complex oxide inclusions, and the effect of inclusions on prior austenite grain size and acicular ferrite (AF) nucleation were studied. The sampling nodes are before ladle furnace (LF) refining, add Ti, add Al, add Mg, add Ca, after Ruhrstahl-Heraeus (RH) refining, respectively. The results show that with the addition of Ti\Al\Mg\Ca, the core of inclusion gradually becomes Al2O3, Al–Ti–O, Al–Ti–Mg–O, Al–Ti–Mg–Ca–O, and a small amount of MnS is wrapped in the outer layer. After RH refining, the core of inclusion is Al–Mg–Ca–O, and a small amount of Ti–O–N and Al–Mg–O are enriched in the outer layer. These inclusions effectively induced AF nucleation. As the smelting process progresses, the average size of inclusions gradually decreases from 0.55 to 0.2 μm, and the number density and percentage of small size inclusions (0.1 to 0.2 μm) gradually increase. After RH refining, the nucleation probability of AF (NAF) of small size inclusions is 7.8 pct, and the NAF of inclusions in the range of 0.4 to 0.8 μm is greater than 70 pct. The small size inclusions are an important part of inducing AF nucleation, which can also effectively pin the prior austenite grain boundaries, and the larger the proportion of small size inclusions, the finer the prior austenite grains.

Similar content being viewed by others

References

X. Luo, G. Xu, X. Chen, and Z. Wang: Mater. Sci. Eng. A, 2022, vol. 833, p. 142571 https://doi.org/10.1016/j.msea.2021.142571.

H. Deng, Z. Liu, X. Wang, J. Ma, F. Han, and Z. Wang: Mater. Today Commun., 2022, vol. 33, p. 104407 https://doi.org/10.1016/j.mtcomm.2022.104407.

W. Guo, Y. Cai, B. Wang, W. Mu, and D. Xin: Mater. Sci. Eng. A, 2022, vol. 830, p. 142240 https://doi.org/10.1016/j.msea.2021.142240.

X. Li, X. Ma, S.V. Subramanian, C. Shang, and R.D.K. Misra: Mater. Sci. Eng. A, 2014, vol. 616, pp. 141–47. https://doi.org/10.1016/j.msea.2014.07.100.

W.-H. Choi, S.-K. Cho, K.W.-K. Choi, and J.-M. Han: J. Korean Weld. Join. Soc., 2012, vol. 30, pp. 64–71. https://doi.org/10.5781/kwjs.2012.30.1.64.

Z. Xiong, S. Liu, X. Wang, C. Shang, and R.D.K. Misra: Mater Charact, 2015, vol. 106, pp. 232–39. https://doi.org/10.1016/j.matchar.2015.06.001.

S.J. Lv, H.H. Wu, K.Y. Wang, S.Z. Wang, G.L. Wu, J.H. Gao, X.S. Yang, J.M. Zhu, and X.P. Mao: Comput. Mater. Sci., 2023, vol. 218, p. 111989 https://doi.org/10.1016/j.commatsci.2022.111989.

W.L. Costin, O. Lavigne, and A. Kotousov: Mater. Sci. Eng. A, 2016, vol. 663, pp. 193–203. https://doi.org/10.1016/j.msea.2016.03.103.

H. Zhao, B.P. Wynne, and E.J. Palmiere: J. Mater. Sci., 2018, vol. 53, pp. 3785–3804. https://doi.org/10.1007/s10853-017-1781-3.

H.S. Kim, M. Jo, J.Y. Park, B.J. Kim, H.C. Kim, D. Nam, B. Kim, and Y.S. Ahn: Mater. Sci. Eng. A, 2022, vol. 857, p. 144125 https://doi.org/10.1016/j.msea.2022.144125.

Y. Shao, C. Liu, Z. Yan, H. Li, and Y. Liu: J. Mater. Sci. Technol., 2018, vol. 34, pp. 737–44. https://doi.org/10.1016/j.jmst.2017.11.020.

Y. Kang, S. Jeong, J.H. Kang, and C. Lee: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 2842–54. https://doi.org/10.1007/s11661-016-3456-0.

J.H. Shim, Y.W. Cho, S.H. Chung, J.D. Shim, and D.N. Lee: Acta Mater., 1999, vol. 47, pp. 2751–60. https://doi.org/10.1016/S1359-6454(99)00114-7.

Z. Zhang and R.A. Farrar: Mater. Sci. Technol., 1996, vol. 12, pp. 237–60. https://doi.org/10.1179/mst.1996.12.3.237.

C. Xuan and W. Mu: Mater. Des., 2022, vol. 221, p. 110892 https://doi.org/10.1016/j.matdes.2022.110892.

J.H. Shim, Y.J. Oh, J.Y. Suh, Y.W. Cho, J.D. Shim, J.S. Byun, and D.N. Lee: Acta Mater., 2001, vol. 49, pp. 2115–22. https://doi.org/10.1016/S1359-6454(01)00134-3.

J.H. Shim, J.S. Byun, Y.W. Cho, Y.J. Oh, J.D. Shim, and D.N. Lee: Scripta Mater., 2001, vol. 44, pp. 49–54. https://doi.org/10.1016/S1359-6462(00)00560-1.

T. Furuhara, T. Shinyoshi, G. Miyamoto, J. Yamaguchi, N. Sugita, N. Kimura, N. Takemura, and T. Maki: ISIJ Int., 2003, vol. 43, pp. 2028–37. https://doi.org/10.2355/isijinternational.43.2028.

Y. Morikage, K. Oi, F. Kawabata, and K. Amano: Tetsu-To-Hagane/J. Iron Steel Inst. Jpn, 1998, vol. 84, pp. 510–15. https://doi.org/10.2355/tetsutohagane1955.84.7_510.

H.H. Jin, J.H. Shim, Y.W. Cho, and H.C. Lee: ISIJ Int., 2003, vol. 43, pp. 1111–13. https://doi.org/10.2355/isijinternational.43.1111.

Ø. Grong, A.O. Kluken, H.K. Nylund, A.L. Dons, and J. Hjelen: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 525–34. https://doi.org/10.1007/BF02663903.

S. Zhang, N. Hattori, M. Enomoto, and T. Tarui: ISIJ Int., 1996, vol. 36, pp. 1301–09. https://doi.org/10.2355/isijinternational.36.1301.

B. Zhou, G. Li, X. Wan, Y. Li, and K. Wu: Met. Mater. Int., 2016, vol. 22, pp. 267–75. https://doi.org/10.1007/s12540-016-5301-9.

F.C. Liu, J.W. Li, Q. Wang, Y.D. Liu, Y. Bai, T. He, and G. Yuan: Mater. Sci. Eng. A, 2021, vol. 824, p. 141795 https://doi.org/10.1016/j.msea.2021.141795.

H.K. Sung, S.S. Sohn, S.Y. Shin, K.S. Oh, and S. Lee: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 3036–50. https://doi.org/10.1007/s11661-014-2240-2.

M.M. Song, B. Song, S.H. Zhang, Z.L. Xue, Z.B. Yang, and R.S. Xu: ISIJ Int., 2017, vol. 57, pp. 1261–67. https://doi.org/10.2355/isijinternational.ISIJINT-2017-037.

C.R. Manuel, M.R. Marcos, A.H.T. Martín, S.M. Rodolfo, C.U. Fabián, and M.E. Arturo: J. Mater. Res. Technol., 2022, vol. 21, pp. 3870–84. https://doi.org/10.1016/j.jmrt.2022.10.105.

G. Xu: J. Steel, 2006, vol. 2, pp. 12–15. https://doi.org/10.3969/j.issn.1002-1043.2006.01.005.

F.J. Li, H.G. Li, D. Huang, S.B. Zheng, and J.L. You: Met. Mater. Int., 2018, vol. 24, pp. 1394–1402. https://doi.org/10.1007/s12540-018-0141-4.

J.S. Seo, K.H. Kim, H.J. Kim, and C. Lee: Weld. World, 2013, vol. 57, pp. 65–72. https://doi.org/10.1007/s40194-012-0009-z.

W. Liu, M. Li, S. Yang, Z. Xu, C. Huang, T. Liu, and J. Li: J. Mater. Res. Technol., 2022, vol. 18, pp. 990–97. https://doi.org/10.1016/j.jmrt.2022.03.014.

P.J. Chen, C.Y. Zhu, G.Q. Li, Y.W. Dong, and Z.C. Zhang: ISIJ Int., 2017, vol. 57, pp. 1019–28. https://doi.org/10.2355/isijinternational.ISIJINT-2017-007.

T.K. Lee, H.J. Kim, B.Y. Kang, and S.K. Hwang: ISIJ Int., 2000, vol. 40, pp. 1260–68. https://doi.org/10.2355/isijinternational.40.1260.

F. Liu, Q. Wang, J. Li, Y. Liu, T. He, and G. Yuan: Mater Charact, 2021, vol. 181, p. 111503 https://doi.org/10.1016/j.matchar.2021.111503.

O. Grong, L. Kolbeinsen, C. van der Eijk, and G. Tranell: ISIJ Int., 2006, vol. 46, pp. 824–31. https://doi.org/10.2355/isijinternational.46.824.

J.L. Lee: Acta Metall. Mater., 1994, vol. 42, pp. 3291–98. https://doi.org/10.1016/0956-7151(94)90461-8.

F.J. Barbaro, P. Krauklis, and K.E. Easterling: Mater. Sci. Technol., 1989, vol. 5, pp. 1057–68. https://doi.org/10.1179/mst.1989.5.11.1057.

D.S. Sarma, A.V. Karasev, and P.G. Jonsson: ISIJ Int., 2009, vol. 49, pp. 1063–74. https://doi.org/10.2355/isijinternational.49.1063.

T. Pan, Z. Yang, B. Bai, and H. Fang: Acta Metall. Sin., 2003, vol. 39, pp. 1037–42. https://www.ams.org.cn/CN/Y2003/V39/I10/1037.

M. Lee, N. Kang, S. Liu, and K. Cho: Sci. Technol. Weld. Join., 2016, vol. 21, pp. 711–19. https://doi.org/10.1080/13621718.2016.1178833.

L. Lan, C. Qiu, and L. Du: Theor. Appl. Fract. Mech., 2023, vol. 124, p. 103762 https://doi.org/10.1016/j.tafmec.2023.103762.

H. Zhao and E.J. Palmiere: Mater Charact, 2018, vol. 145, pp. 479–89. https://doi.org/10.1016/j.matchar.2018.09.013.

C.K. Lin, Y.H. Su, W.S. Hwang, G.R. Lin, and J.C. Kuo: Mater. Sci. Technol., 2018, vol. 34, pp. 596–606. https://doi.org/10.1080/02670836.2017.1421037.

Acknowledgments

The authors are grateful for the financial support from the Key R&D Program of Shandong Province, China (No. 2023CXGC010310).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Contributions

Yansen Hao helped us to obtain the samples in smelting process in the factory, which is the basis for the experiment in this paper.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jia, X., Li, H., Yang, Y. et al. Evolution of Complex Oxide Inclusions During the Smelting Process of Oxide Metallurgical Steel and Their Effect on Acicular Ferrite Nucleation. Metall Mater Trans A 55, 724–735 (2024). https://doi.org/10.1007/s11661-023-07266-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07266-8