Abstract

The influence of texture on strength was investigated by altering the amount of cobalt in Ni-Co alloys. The purpose of incorporating Co was to reduce the stacking fault energy (SFE) of the alloy. A decrease in the SFE reduces the ease of cross-slip and enhances planar slip, leading to changes in texture during cold working. Three Ni-Co alloys (33, 50, and 60 wt pctCo) were wire drawn at room temperature in a specially designed setup to wire diameters of 500, 200, and 100 μm, corresponding to a drawing strain of 2.67, 4.05, and 5.88. EBSD analysis revealed a refinement in grain size with drawing strain as well as a transition from elongated to equiaxed grains in Ni-50 and Ni-60 Co alloys. Line profile analysis and bulk texture analysis showed that increasing drawing strain leads to a higher defect density, an increased <100> fiber fraction and a decreased <111> fiber fraction, with the trends increasing with an increase in Co content. Tensile tests on the drawn wires show that Ni-60 Co alloy has higher strength with superior ductility for all wire diameters. The HP coefficients for the annealed conditions, calculated by annealing Ni-Co wires of 100 μm diameter, was found to be independent of SFE. The HP coefficients in drawn conditions were found to be higher than in the annealed conditions. The activation volume measured from the multiple stress relaxations in the drawn wires ranged from 20 to 5.5 b3, suggesting that dislocation interactions remained the underlying operating deformation mechanism.

Similar content being viewed by others

References

E.O. Hall: Proc. Phys. Soc. Sect. B, 1951, vol. 64, pp. 747–53.

N.J. Petch: J. Iron Steel Inst., 1953, vol. 174, pp. 25–28.

S. Floreen and J.H. Westbrook: Acta Met., 1969, vol. 17, pp. 1175–81.

R.Z. Valiev, N.A. Enikeev, M.Y. Murashkin, S.E. Aleksandrov, and R.V. Goldshtein: Dokl. Phys., 2010, vol. 55, pp. 267–70.

N. Hansen: Acta Met., 1977, vol. 25, pp. 863–69.

R. Kamel and T.H. Youssef: Acta Met., 1967, vol. 15, pp. 965–70.

F. Emeis, M. Peterlechner, and G. Wilde: Adv. Eng. Mater., 2020, vol. 22, pp. 1–10.

R. Armstrong, I. Codd, R.M. Douthwaite, and N.J. Petch: Philos. Mag., 1962, vol. 7, pp. 45–58.

J. Nuttall and J. Nutting: Met. Sci., 1978, vol. 12, pp. 430–37.

D.A. Hughes and N. Hansen: Acta Mater., 2000, vol. 48, pp. 2985–3004.

A. Arya, S. Suwas, C. Gérard, L. Signor, L. Thilly, and A.H. Chokshi: Acta Mater., 2021, vol. 221, pp. 1–10.

G. Sambasiva Rao and Y.V.R.K. Prasad: Metall. Trans. A, 1982, vol. 13A, pp. 2219–26.

L. Feng, Y.Y. Ren, Y.H. Zhang, S. Wang, and L. Li: Metals (Basel), 2019, vol. 9, pp. 1–8.

S. Suwas and S. Mondal: Mater. Trans., 2019, vol. 60, pp. 1457–71.

D.A. Hughes and W.D. Nix: Mater. Sci. Eng. A, 1989, vol. 122, pp. 153–72.

Y.H. Zhao, Y.T. Zhu, X.Z. Liao, Z. Horita, and T.G. Langdon: Appl. Phys. Lett., 2006, vol. 89, pp. 2004–07.

R.K. Ray: Acta Metall. Mater., 1995, vol. 43, pp. 3861–82.

N. Hansen: Metall. Trans. A, 1985, vol. 16, pp. 2167–90.

R.Z. Valiev, K. Islamgaliev, and I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103–89.

Y. Cao, S. Ni, Liao, M. Song, and Y. Zhu: Mater. Sci. Eng. R, 2018, vol. 133, pp. 1–59.

G.V. Nurislamova, R.K. Islamgaliev, and R.Z. Valiev: Mater. Sci. Forum, 2006, vol. 503–504, pp. 579–84.

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, and Y.T. Zhu: J. Miner. Mater. Mater. Soc., 2006, vol. 1, pp. 33–39.

V.M. Segal: Mater. Sci. Eng. A, 2002, vol. 338, pp. 331–44.

K. Neishi, Z. Horita, and T.G. Langdon: Mater. Sci. Eng. A, 2002, vol. 325, pp. 54–58.

K. Edalati, A. Bachmaier, V.A. Beloshenko, Y. Beygelzimer, V.D. Blank, W.J. Botta, K. Bryła, J. Čížek, S. Divinski, N.A. Enikeev, Y. Estrin, G. Faraji, R.B. Figueiredo, M. Fuji, T. Furuta, T. Grosdidier, J. Gubicza, A. Hohenwarter, Z. Horita, J. Huot, Y. Ikoma, M. Janeček, M. Kawasaki, P. Král, S. Kuramoto, T.G. Langdon, D.R. Leiva, V.I. Levitas, A. Mazilkin, M. Mito, H. Miyamoto, T. Nishizaki, R. Pippan, V.V. Popov, E.N. Popova, G. Purcek, O. Renk, Á. Révész, Sauvage, V. Sklenicka, W. Skrotzki, B.B. Straumal, S. Suwas, L.S. Toth, N. Tsuji, R.Z. Valiev, G. Wilde, M.J. Zehetbauer, and Zhu: Mater. Res. Lett., 2022, vol. 10, pp. 163–256.

K. Edalati and Z. Horita: Acta Mater., 2011, vol. 59, pp. 6831–36.

F.A. Mohamed: Acta Mater., 2003, vol. 51, pp. 4107119.

G. Bojjawar, S. Suwas, and A.H. Chokshi: Philos. Mag. Lett., 2022, vol. 102, pp. 1–4.

D. Caillard and J.L. Martin: Thermally Activated Mechanisms in Crystal Plasticity, 2003, vol. 8, p. 1.

W. Blum: Scripta Mater., 2018, vol. 146, pp. 27–30.

S. Qu, X.H. An, H.J. Yang, C.X. Huang, G. Yang, Q.S. Zang, Z.G. Wang, S.D. Wu, and Z.F. Zhang: Acta Mater., 2009, vol. 57, pp. 1586–1601.

Y.T. Zhu, X.Z. Liao, X.L. Wu, and J. Narayan: J. Mater. Sci., 2013, vol. 48, pp. 4467–75.

A.Y. Chen, H.H. Ruan, J. Wang, H.L. Chan, Q. Wang, Q. Li, and J. Lu: Acta Mater., 2011, vol. 59, pp. 3697–3709.

M.R. Staker and D.L. Holt: Acta Met., 1972, vol. 20, pp. 569–79.

P. Landau, R.Z. Shneck, G. Makov, and A. Venkert: IOP Conf. Ser. Mater. Sci. Eng., 2009, vol. 3, pp. 1–6.

W. Wu, M. Song, S. Ni, J. Wang, Y. Liu, B. Liu, and Liao: Sci. Rep., 2017, vol. 7, pp. 1–3.

N.R. Tao and K. Lu: Scripta Mater., 2009, vol. 60, pp. 1039–43.

Y.T. Zhu, X.Z. Liao, and X.L. Wu: Prog. Mater. Sci., 2012, vol. 57, pp. 1–62.

R. Jamaati and M.R. Toroghinejad: Adv. Mater. Res., 2014, vol. 1064, pp. 131–37.

J.C. Eckert, J. Holzer, I.C.E. Krill, and W.L. Jhonson: J. Mater. Res., 1992, vol. 7, pp. 1751–61.

T.D. Shen and C.C. Koch: Mater. Sci. Forum, 1995, vol. 179–181, pp. 17–24.

I.L. Dillamore and W.T. Roberts: Metall. Rev., 1965, vol. 10, pp. 271–380.

H. Ahlborn, J. Grewen, and G. Wassermann: ZEITSCHRIFT FUR Met., 1963, vol. 55, pp. 588–99.

B.D. Cullity: Metall. Rev., 1958, vol. 10, pp. 271–371.

Y.H. Zhao, J.F. Bingert, Y.T. Zhu, X.Z. Liao, R.Z. Valiev, Z. Horita, T.G. Langdon, Y.Z. Zhou, and E.J. Lavernia: Appl. Phys. Lett., 2008, vol. 92, pp. 23–25.

U.F. Kocks and H. Mecking: Prog. Mater. Sci., 2003, vol. 48, pp. 171–273.

C.A. Schuh, T.G. Nieh, and H. Iwasaki: Acta Mater., 2003, vol. 51, pp. 431–43.

N. Hansen: Scripta Mater., 2004, vol. 51, pp. 801–06.

A. Godon, J. Creus, S. Cohendoz, E. Conforto, Feaugas, P. Girault, and C. Savall: Scripta Mater., 2010, vol. 62, pp. 403–06.

P. Ghosh, S. Van Petegem, H. Van Swygenhoven, and A.H. Chokshi: Mater. Sci. Eng. A, 2017, vol. 701, pp. 101–10.

Z.H. Cao, L. Wang, K. Hu, Y.L. Huang, and X.K. Meng: Acta Mater., 2012, vol. 60, pp. 6742–54.

Acknowledgment

The work was supported by science and engineering research board (SERB), department of science and technology, Government of India.

Competing interest

The authors declare that they have no known financial competing interests or personal relationships that could have influenced the work reported in the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix

See Figure A1.

Microstructure of annealed Ni-Co wires

See Figures A2, A3, A4, and Table AI.

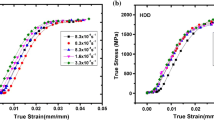

Tensile Test Data of Ni-Co Annealed Wires

See Figure A5.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bojjawar, G., Suwas, S. & Chokshi, A.H. The Effect of Texture on the Hall-Petch Relationship in Severely Drawn Ni-Co Microwires. Metall Mater Trans A 55, 232–246 (2024). https://doi.org/10.1007/s11661-023-07245-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07245-z