Abstract

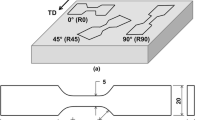

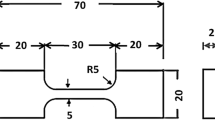

In this study, the effect of plastic deformation on strength, work hardening behavior, fracture toughness (FT, JIc), and fatigue crack growth rate (FCGR) of Ti–6Al–4V alloy in annealed condition was studied. Ti–6Al–4V was subjected to uniaxial pre-strain of 0.5, 1, 2, 3, 4, and 5 pct and tensile, JIc and FCGR specimens were extracted from the pre-strained material. X-ray diffraction analysis revealed peak broadening with increasing strain. Both the ultimate tensile strength (UTS) and yield strength (YS) were found to significantly increase with increasing pre-strain, whereas the ductility was retained up to 4 pct pre-strain. Beyond 4 pct pre-strain, the ductility decreased drastically. Strain hardening exponent, work hardening rate, and maximum work hardening decreased with increasing uniaxial pre-strain. This study revealed that, up to 1 pct pre-strain, the JIc values get slightly affected, beyond which they get significantly reduced. Resistance to fatigue crack propagation was significantly lowered for pre-strained specimens. No significant FCGR variations were observed among specimens subjected to different levels of pre-strains. Pre-strain increases misorientation accumulation, average misorientation and dislocation density, which resulted in an increase in both YS and UTS and a decrease in the ductility significantly. Increase in deformation heterogeneity was observed at higher pre-strains due to the evolution of deformation texture. Textured region increases plastic strain heterogeneities and alters the mechanism of crack initiation and crack propagation. Pre-strain significantly influences FT and FCGR properties of this alloy.

Similar content being viewed by others

References

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill Book Company, London, 2011.

M.J. Donachie: Titanium, ASM International, Novelty, 2000.

I. Polmear: Light Alloys, 4th ed. Elsevier, New York, 2005.

D. Banerjee and J.C. Williams: Acta Mater., 2013, vol. 61, pp. 844–79.

D. Dawicke and J. Lewis: in 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, American Institute of Aeronautics and Astronautics, Reston, VA, 2009.

Y. Yang, L. Zhan, and C. Liu: Int. J. Light Mater. Manuf., 2020, vol. 3, pp. 73–76.

H. Li, L. Zhan, M. Huang, X. Zhao, C. Zhou, and Z. Qiang: J. Alloys Compd., 2021, vol. 851, p. 156829.

J. Li, S. Kim, T.M. Lee, P.E. Krajewski, H. Wang, and S.J. Hu: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3905–14.

G.K. Quainoo and S. Yannacopoulos: J. Mater. Sci., 2004, vol. 39, pp. 4841–47.

N. Han, X. Zhang, S. Liu, B. Ke, and X. Xin: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3714–21.

S. Kilic, I. Kacar, M. Sahin, F. Ozturk, and O. Erdem: Mater. Res., 2019, https://doi.org/10.1590/1980-5373-mr-2019-0006.

K. Alrubaie, E. Barroso, and L. Godefroid: Int. J. Fatigue, 2006, vol. 28, pp. 934–42.

S. Sivaprasad, S. Tarafder, V.R. Ranganath, and K.K. Ray: Mater. Sci. Eng. A, 2000, vol. 284, pp. 195–201.

K. Amouzouvi and M. Bassim: Mater. Sci. Eng., 1983, vol. 60, pp. 1–5.

Z. Yang and Z. Wang: Mater. Sci. Eng. A, 1996, vol. 210, pp. 83–93.

H. Ni and Z. Wang: Mater. Sci. Eng. A, 2001, vol. 314, pp. 12–23.

P.S. De, A. Kundu, and P.C. Chakraborti: Mater. Des., 2014, vol. 57, pp. 87–97.

Y. Madi, Y. Shinohara, and J. Besson: Int. J. Fract., 2020, vol. 224, pp. 15–29.

J. Peng, K. Li, J. Peng, J. Pei, and C. Zhou: Mater. Sci. Technol., 2018, vol. 34, pp. 547–60.

H. Wu, H. Hamada, and S. Noguchi: in 19th European Conference on Fracture: Fracture Mechanics for Durability, Reliability and Safety, ECF 2012, European Conference on Fracture, ECF, 2012.

J.K. Mahato, P.S. De, A. Sarkar, A. Kundu, and P.C. Chakraborti: Procedia Eng., 2014, vol. 74, pp. 368–75.

J.D. Parker and B. Wilshire: Mater. Sci. Eng., 1980, vol. 43, pp. 271–80.

J. Li, P. Zhang, L. Lu, F. Lv, X.-T. Miao, L. Chang, B.-B. Zhou, X.-H. He, and C.-Y. Zhou: Int. J. Fatigue, 2018, vol. 117, pp. 27–38.

Z. Lincai, D. Xiaoming, Y. Wei, Z. Man, and S. Zhenya: High Temp. Mater. Process., 2018, vol. 37, pp. 487–93.

M. Whittaker, P. Jones, C. Pleydell-Pearce, D. Rugg, and S. Williams: Mater. Sci. Eng. A, 2010, vol. 527, pp. 6683–89.

Z.Y. Song, Q.Y. Sun, L. Xiao, L. Liu, and J. Sun: Mater. Sci. Eng. A, 2010, vol. 527, pp. 691–98.

D.B. Lanning, T. Nicholas, and G.K. Haritos: Mech. Mater., 2002, vol. 34, pp. 127–34.

T. Wu, N. Wang, M. Chen, D. Zuo, L. Xie, and W. Shi: Metals (Basel), 2021, vol. 11, p. 1321.

ASTM: ASTM E8: ASTM Book of Standards, ASTM, West Conshohocken, 2021, pp. 1–30.

K. Thool, A. Patra, D. Fullwood, K.V.M. Krishna, D. Srivastava, and I. Samajdar: Int. J. Plast., 2020, vol. 133, p. 102785.

S.I. Wright, M.M. Nowell, and D.P. Field: Microsc. Microanal., 2011, vol. 17, pp. 316–29.

S.I. Wright, S. Suzuki, and M.M. Nowell: JOM, 2016, vol. 68, pp. 2730–36.

ASTM: E1820: ASTM Book of Standards, vol. 3.01, ASTM, West Conshohocken, 2013, pp. 1–65.

ASTM: E 646: ASTM Book of Standards, vol. 03, ASTM, West Conshohocken, 2016, pp. 1–8.

ASM: Mechanical Testing and Evaluation, ASM International, Novelty, 2000.

S. Ali, R. Karunanithi, M. Prashanth, and M.A. Rahman: Mater. Today Proc., 2020, vol. 27, pp. 2390–93.

T.H. Simm, P.J. Withers, and J. Quinta da Fonseca: J. Appl. Crystallogr., 2014, vol. 47, pp. 1535–51.

G. Williamson and W. Hall: Acta Metall., 1953, vol. 1, pp. 22–31.

A.W. Bowen: Acta Metall., 1978, vol. 26, pp. 1423–33.

A.A. Kaminskii and S.B. Nizhnik: Int. Appl. Mech., 1995, vol. 31, pp. 777–98.

G.I.U.A.A. Kaminsky and S.B. Nizhnik: Met. Adv. Technol., 2001, vol. 23, pp. 1483–99.

R.W.K. Honeycombe: The Plastic Deformation of Metals, Edward Arnold, Maidenhead, 1984.

R.E. Jones: Eng. Fract. Mech., 1973, vol. 5, pp. 585–604.

J. Chesnutt, J.C. Rhodes, and C.G. Williams: Fractography—Microscopic Cracking Processes, ASTM International, West Conshohocken, 1976.

G.R. Yoder, L.A. Cooley, and T.W. Crooker: J. Eng. Mater. Technol., 1977, vol. 99, pp. 313–18.

G.R. Yoder, L.A. Cooley, and T.W. Crooker: Metall. Trans. A, 1977, vol. 8, pp. 1737–43.

G.R. Yoder, L.A. Cooley, and T.W. Crooker: Eng. Fract. Mech., 1979, vol. 11, pp. 805–16.

D. Eylon, J.A. Hall, C.M. Pierce, and D.L. Ruckle: Metall. Trans. A, 1976, vol. 7, pp. 1817–26.

K.S. Ravichandran: Acta Metall. Mater., 1991, vol. 39, pp. 401–10.

S. Shademan, V. Sinha, A.B.O. Soboyejo, and W.O. Soboyejo: Mech. Mater., 2004, vol. 36, pp. 161–75.

T. Akahori, M. Niinomi, K.-I. Fukunaga, and I. Inagaki: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1949–58.

P.A. Eikrem, Z.L. Zhang, and B. Nyhus: Int. J. Press. Vessel Pip., 2007, vol. 84, pp. 708–15.

S. Hémery, P. Villechaise, and D. Banerjee: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 4931–69.

Z. Zheng, D.S. Balint, and F.P.E. Dunne: Acta Mater., 2017, vol. 127, pp. 43–53.

S.K. Mishra, P. Pant, K. Narasimhan, A.D. Rollett, and I. Samajdar: Scripta Mater., 2009, vol. 61, pp. 273–76.

N. Pai, A. Prakash, I. Samajdar, and A. Patra: Int. J. Plast., 2022, vol. 156, p. 103360.

P.M. Souza, P.D. Hodgson, B. Rolfe, R.P. Singh, and H. Beladi: J. Alloys Compd., 2019, vol. 793, pp. 467–79.

Acknowledgments

The authors are also thankful to Director, Vikram Sarabhai Space Centre (Trivandrum, India), for the kind permission to publish this article.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saravanan, K., Manikandan, P., Jalaja, K. et al. Effect of Uniaxial Pre-strain on Tensile, Work Hardening, Fracture Toughness, and Fatigue Crack Growth Rate of Titanium Alloy Ti–6Al–4V. Metall Mater Trans A 54, 3603–3619 (2023). https://doi.org/10.1007/s11661-023-07117-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07117-6