Abstract

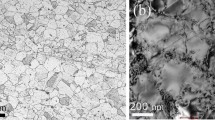

A mechanism is established by which interstitial impurity content increases the high-temperature strength of niobium. A Type 2 niobium sheet material (ASTM B393-18) was mechanically tested in tension from 1473 K to 1773 K (1200 °C to 1500 °C) at constant true strain rates of 10−3 and 10−4 s−1. This material is compared to a Type 1 niobium with lower interstitial impurity levels. The microstructures of both materials are characterized using backscatter electron imaging (BSE) and electron backscatter diffraction (EBSD). The deformation of both materials at these temperatures is dominated by five-power creep and the associated development of subgrains that control strength. Compared to the Type 1 material, the higher interstitial impurity content of the Type 2 niobium produces: 1. higher strength at elevated temperatures, 2. delayed recrystallization, 3. slower grain growth, 4. more inhomogeneous microstructures, and 5. slower recovery that produces smaller subgrains. These result from the fine dispersoids expected from interstitial impurities in the Type 2 niobium, with carbon identified as the most important interstitial element. The finer subgrain size of the Type 2 niobium produces, through five-power creep, a higher strength than the Type 1 niobium at these high temperatures.

Similar content being viewed by others

References

T.H. Schofield: J. Inst. Met., 1956, vol. 85, pp. 372–74.

J.B. Lambert and J.J. Rausch: Prop. Sel. Nonferrous Alloy. Spec. Mater., 2018, vol. 2, pp. 557–85.

ASTM: ASTM B393-18, 2015, vol. 03, pp. 14–17.

W. Chang: in Refract. Met. Alloy., J.J. Semchyshen, M. and Harwood, ed., Metallurgical Society of AIME, 1958, pp. 83–117.

E. Orowan: in Symp. Intern. Stress. Met. Alloy., Institue of Metals, London, 1948, pp. 47-58.

J.C. Fisher, E.W. Hart, and R.H. Pry: Acta Metall., 1953, vol. 1, pp. 336–39.

M.J. Klein and A.G. Metcalfe: Metall. Trans., 1973, vol. 4, pp. 2441–48.

J. Weertman: Nav. Res. Lab Report 5123, 1958.

E.A.D. Brady and E.M. Taleff: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 1095–1105.

A.N. Behera, R. Kapoor, A. Sarkar, and J.K. Chakravartty: Energy Mater. Mater. Sci. Eng. Energy Syst., 2014, vol. 9, pp. 637–44.

G. Brinson and B.B. Argent: J. Inst. Met., n.d., vol. 91, pp. 293–98.

M.J. Klein and M.E. Gulden: Metall. Trans., 1973, vol. 4, pp. 2175–80.

J.D.W. Rawson and B.B. Argent: J. Inst. Met., 1967, vol. 95, pp. 212–16.

Plansee: https://www.Plansee.Com/En/Materi%0Aals/Niobium.html. n.d.

Ralph Hielscher: MTEX Github, https://www.Github.Com/Mtex-Toolbox/Mtex/Blob/Develop/EBSDAnalysis/@EBSD/Fill.M. n.d.

ASTM International: ASTM, 2010, vol. E112–10, pp. 1–27.

T. R. McNelley, K. Oh-Ishi, A. P. Zhilyaev, S. Swaminathan, P.E. Krajewski, and E.M. Taleff: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 50–64.

J. Stoop and P. Shahinian: Rep. No. NRL-6095, 1964, pp. 407–32.

J. Stoop and P. Shahinian: Rep. No. NRL-6464, 1966, pp. 1–15.

C. J. Smithells: Smithells Metals Reference Book, 2004.

S.R. Shatynski: Oxid. Met., 1979, vol. 13, pp. 105–18.

O.D. Sherby, R.H. Klundt, and A.K. Miller: Metall. Mater. Trans. A, 1977, vol. 8, pp. 843–50.

C. Zener and J.H. Hollomon: J. Appl. Phys., 1944, vol. 15, pp. 22–32.

O.D. Sherby and P.M. Burke: Prog. Mater. Sci., 1968, vol. 13, pp. 325–90.

O.A. Ruano and O.D. Sherby: Rev. Phys. Appl., 1988, vol. 23, pp. 625–37.

M.E. Kassner: Fundamentals of Creep in Metals and Alloys, Butterworth Heinemann, Wal Tham, MA, 2015.

Ya. S. Malakhov and G. V. Samsonov: Poroshkovaya Metall., 1966, pp. 84–91.

F.A. Mohamed and T.G. Langdon: Acta Metall., 1974, vol. 22, pp. 779–88.

W.R. Cannon and O.D. Sherby: Metall. Mater. Trans. A, 1970, vol. 1A, pp. 1030–32.

Acknowledgments

The authors thank the National Science Foundation for sponsoring this work under Grants DMR-1507417 and DMR-2003312 and equipment under Grant DMR-9974476. The authors also thank the Center for Integrated Nanotechnologies (CINT), an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Los Alamos National Laboratory (Contract 89233218CNA000001) and Sandia National Laboratories (Contract DE-NA-0003525), where some data were collected.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Brady, E.A.D., Taleff, E.M. The Effects of Impurity Content on Plastic Deformation and Microstructure Evolution in Niobium at Temperatures from 1473 K to 1773 K. Metall Mater Trans A 53, 3057–3072 (2022). https://doi.org/10.1007/s11661-022-06726-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06726-x