Abstract

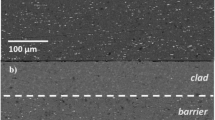

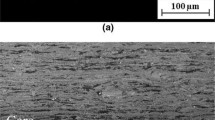

A high-strength aluminum brazing sheet product has been developed for automotive heat exchangers. It consists of commercial Al-Si clad, newly designed Al-Mn-Cu-Mg core, and pure aluminum barrier between the clad and core. The microstructure, mechanical properties, corrosion resistance, and braze-ability were investigated and compared with regular brazing sheets without barrier. The newly designed Al-Mn-Cu-Mg alloys are much stronger than commercial Al-Mn-Cu core alloys and the high strength is maintained up to 573.15 K (300 °C). However, liquid–solid interaction occurs extensively during brazing when the Al-Si clad contacts the Al-Mn-Cu-Mg core directly, resulting in degrading of mechanical properties and corrosion resistance. The barrier provides a physical separation between the clad and core, preventing not only the liquid–solid interaction, but also the solid diffusion of Si from clad to core and Mg from core to sheet surface. The accumulation of Si and Mg in the barrier leads to a high population density of Mg2Si precipitates, acting as a sacrificial band to delay the through-thickness corrosion. Meanwhile, the low Mg level in the sheet surface ensures high braze-ability for commercial flux brazing processes. The new sheet product is therefore suitable to high-performance automotive heat exchangers, especially the ones that may serve at temperatures above 473.15 K (200 °C).

Similar content being viewed by others

References

[1] M.M. Schwartz: Brazing, ASM International, Materials Park, 1987.

[2] G. Humpston and D.M. Jacobson: Principle of Soldering and Brazing, ASM international, Materials Park, 1991.

[3] R. Woods: CAB Brazing Metallurgy, 12th Annual International Invitational Aluminum Brazing Seminar, AFC Holcroft, Novi, 2007.

[4] M.P. Groover: Fundamentals of Modern Manufacturing: Materials Processes and Systems, Wiley, Hoboken, 2007.

J. Liu: NOCOLOK Flux and Aluminum Brazing, SAE Technical Paper 960244, 1996.

[6] H. Jin, J. Liang, Y. Zeng and M. S. Kozdras: SAE Int. J. Mater. Manf., 2015, vol. 8(3), pp. 736-43.

[7] H. Jin, M.S. Kozdras, B. Shalchi-Amirkhiz and S.L. Winkler: Metall. Mater. Trans., 2018, vol. 49A, pp. 3091-3108.

[8] F.P. Incropera, D.P. DeWitt, T.L. Bergman and A.S. Lavine: Introduction to Heat Transfer, Wiley, Hoboken, 2007.

[9] E.A.D. Saunders: Heat Exchanges: Selection, Design and Construction, Wiley, New York, 1988.

[10] J.B. Heywood: Internal Combustion Engine Fundamentals, McGraw-Hill, New York, 1988.

[11] B. Hu, J.W.G. Turner, S. Akehurst, C. Brace and C. Copeland: J. Auto. Eng., 2017, vol. 231(4), pp. 435-56.

[12] H. Jin: Metall. Mater. Trans., 2019, vol. 49A, pp. 3091-3108.

[13] M. Nylén, U. Gustavsson, B. Hutchinson and A. Örtnäs: Mater. Sci. Forum, 2000, vol. 331-337, pp. 1737-42.

S.D. Meijers: Corrosion of aluminium brazing sheet, Ph.D. Thesis, Delft University of Technology, 2002.

[15] A.J. Wittebrood, S. Desikan, R. Boom and L. Katgerman: Mater. Sci. Forum, 2006, vol. 519-521, pp. 1151-56.

A. Wittebrood: Microstructural changes in brazing sheet due to sold-liquid interaction, Ph.D. Thesis, Delft University of Technology, 2009.

P.E. Fortin, P.H. Marois and D.G.S. Evans: US Patents 5037707 and 5041343, August 1991.

A. Gray, G.J. Marshall and A.J.E. Flemming: International Patent WO 94/22633, October 1994.

[19] G.J. Marshall, R.K. Bolingbroke and A. Gray: Metall. Trans., 1993, vol. 24A, pp. 1935-42.

G.J. Marshall, A.J.E. Flemming, A. Gray and R. Llewellyn: Proc. 4th Int. Conf. Aluminium and Alloys, Atlanta, USA, 1994, vol. 1, pp. 467-74.

R. Benedictus, S.D. Meijers, A.J. Wittebrood and J.H.W. de Witt: Proc. 6th Int. Conf. Aluminium and Alloys, The Japan Institute of Light Metals, Toyohashi, Japan, 1998, pp. 1577-82.

J. Liu and T. Worlitz: NOCOLOK brazing aluminum heat exchangers, SAE Technical Paper 950117, 1995.

[23] H. Jin, B. Shalchi-Amirkhiz and D.J. Lloyd: Metall. Mater. Trans., 2018, vol. 49A, pp. 1962-79.

[24] H. Jin: Metall. Mater. Trans., 2019, vol. 50A, pp. 3868-90.

[25] L.F. Mondolfo: Aluminum Alloys: Structure and Properties, Butterworth & Co Ltd., London, UK, 1976.

[26] A.S. Argon: Strengthening Mechanisms in Crystal Plasticity, Oxford University Press, Oxford, UK, 2008.

[27] J.E. Hatch: Aluminum: Properties and Physical Metallurgy, American Society for Metals, Metals Park, 1984.

[28] T.W. Clyne and P.J. Withers: An Introduction to Metal Matrix Composites, Cambridge University Press, Cambridge, UK, 1993.

R. Benedictus, A. Burger and A.J.P. Haszler: US Patent 7226669B2, June 2007.

[30] T. Stenqvist, K. Bång, S. Kahl, A. Contet and O. Karlsson: Mater. Sci. Forum, 2014, vol. 794-796, pp. 1239-44.

[31] S.A. Court, K.M. Gatenby and D.J. Lloyd: Mater. Sci. Eng., 2001, vol. A319-321, pp. 443-47.

[32] D.J. Lloyd and S.A. Court: Mater. Sci. Tech., 2003, vol. 19, pp. 1349-54.

[33] H. Jin: Metall. Mater. Trans., 2018, vol. 49A, pp. 6122-33.

S. Esmaeili, Precipitation hardening behaviour of AA6111, Ph.D. Thesis, University of British Columbia, 2002.

ASTM G69-12, Standard Test Method for Measurement of Corrosion Potentials of Aluminum Alloys, ASTM International, West Conshohocken, PA, 2012.

[36] C. Vargel: Corrosion of Aluminium, Elsevier Science, Amsterdam, 2004.

[37] M. Zamin: Corrosion, 1981, vol. 37, pp. 627-32.

[38] R.G. Buchheit: J. Electrochemical Society, 1995, vol. 142, pp. 3994-96.

[39] J.R. Davis: ASM Specialty Handbook: Aluminium and Aluminium alloys, ASM international, Materials Park, 1994.

[40] S. Fujikawa, K. Hirano and Y. Fukushima: Metall. Trans., 1978, vol. 9A, pp. 1811-15.

[41] J. Verlinden and R. Gijbels: Adv. Mass. Spectrom., 1980, vol. 8A, pp. 485-95.

[42] S. Fujikawa and K. Hirano: Def. Diff. Forum, 1989, vol. 66-69, pp. 447-52.

[43] G. Rummel, T. Zumkley, M. Eggersmann, K. Freitag and H. Mehrer: Z. Metallkd., 1995, vol. 86, pp. 122-30.

[44] M.J. Benoit, M.A. Whitney, M.A. Wells, H. Jin and S. Winkler: Metall. Mater. Trans., 2017, vol. 48A, pp. 4645-654.

[45] M.J. Benoit, R. Kaur, M.A. Wells, H. Jin, B. Shalchi-Amirkhiz and S. Winkler: J. Mater. Proc. Tech., 2018, vol. 254, pp. 353-60.

[46] M.J. Benoit, H. Jin, B. Shalchi-Amirkhiz, S. Kurukuri, S. Winkler, M.J. Worswick and M.A. Wells, J. Mater. Proc. Tech., 2020, vol. 281, 116639.

H. Jin, The role of transition metal solutes in the deformation texture, recrystallization and grain growth in aluminum and its alloys, Ph.D. Thesis, Queen’s University at Kingston, 2001.

Acknowledgment

This work was supported by Natural Resources Canada through P-002605.001. Dr. B. Shalchi Amirkhiz is appreciated for the TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 20 October 2020; accepted 29 January 2021.

Rights and permissions

About this article

Cite this article

Jin, H. Development of an Aluminum Brazing Sheet Product with Barrier Layer for High-Performance Automotive Heat Exchangers. Metall Mater Trans A 52, 1409–1426 (2021). https://doi.org/10.1007/s11661-021-06172-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06172-1