Abstract

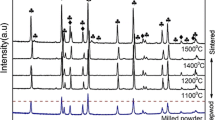

Al2O3-ZrO2-TiC composites with different proportions of TiC were prepared by ball milling and spark plasma sintering. Structural characterization revealed that the composites exhibited fine and homogeneous microstructures. No other phases except α-Al2O3, t-ZrO2 and c-TiC were detected by XRD in all Al2O3-ZrO2-TiC composites. The internal stress induced by the mismatch of the thermal expansion coefficients result in a shift of t-ZrO2 diffraction peak. SEM and TEM observations showed that the Al2O3 grain size was inversely proportional to the TiC content, while the grain sizes of ZrO2 and TiC stayed nearly constant. HRTEM micrograph presented that there are glassy phase boundaries with thickness of several nanometers around the TiC grains. As the TiC content increases, the relative density and hardness decreased from 99.2 to 97.7 pct and from 21.0 to 15.8 GPa, respectively. Compared with Al2O3-ZrO2 matrix, composites with TiC exhibited lower flexural strength but enhanced fracture toughness. Composite with TiC of 10 vol pct possessed the best friction property. The increased porosity was mainly responsible for the deterioration of mechanical and friction properties except for the fracture toughness. The improvement in fracture toughness with increasing TiC content was attribute to the crack deflection and pinning effects induced by the TiC particles.

Similar content being viewed by others

References

1. Y.H. Fang, N. Chen, G.P. Du, M.X. Zhang, X.R. Zhao and J. Wu: Ceram. Int. 2019, vol. 45, pp. 16504-11.

2. O.L. Ighodaro and O.I. Okoli: Int. J. Appl. Ceram. Technol. 2008, vol. 5, pp. 313-23.

S.F. Shi, T. Sekino, S. Cho and T. Goto: Mater. Sci. Eng., A 2020, vol. 777, p. 139066

4. J. Zhang, T.B. Zhu, Y. Cheng, S. Sang, Y. Li, D. An and Z. Xie: Ceram. Int. 2020, vol. 46, pp 25719-25

5. R.H.J. Hannink, P.M. Kelly and B.C. Muddle: J. Am. Ceram. Soc. 2000, vol. 83, pp. 461-87.

6. W. H. Tuan, R.Z. Chen, T.C. Wang, C.H. Cheng and P.S. Kuo: J. Eur. Ceram. Soc. 2002, vol. 22, pp. 2827-33.

7. A.Z.A. Azhar, M.M. Ratnam and Z.A. Ahmad: J. Alloys Compd. 2009, vol. 478, pp. 608-14.

8. S. Meir, S. Kalabukhov and S. Hayun: Ceram. Int. 2014, vol. 40, pp. 12187-92.

J.L. Chai, Y.B. Zhu, Z.G. Wang, T.L. Shen, Y.W. Liu, L.J. Niu, S.F. Li, C.F. Yao, M.H. Cui and C. Liu: Mater. Sci. Eng., A 2020, vol. 781, p. 139197.

10. B. Zhong, G. L. Zhao, X. X. Huang, L. Xia, X. H. Tang, S. C. Zhang and G. W. Wen: J. Eur. Ceram. Soc. 2015, vol. 35, pp. 641-49.

11. J. Gong, H. Miao and Z. Zhao, J. Eur. Ceram. Soc. 2001, vol. 21, pp. 2377-81.

12. K.F. Cai, D. S. McLachlan, N. Axen and R. Manyatsa: Ceram. Int. 2002, vol. 28, pp. 217-22.

M. Cheng, H. Liu, Bin Zhao, C. Huang, P. Yao and B. Wang, Ceram. Int. 2017, vol. 43, pp. 13869-74.

14. P.S. Art and W. Oungkulsolmongkol: J. Met. Mater. Miner. 2010, vol. 20, pp. 71-78.

15. I. Ahmad, S. Ahmed, T. Subhani, K. Saeed, M. Islam, N. Wang and Y. Zhu: Curr. Appl. Phys. 2016, vol. 16, pp. 1649-58.

16. C.F. Gutiérrez-González, M. Suarez, S. Pozhidaev, S. Rivera, P. Peretyagin, W. Solís, L.A. Díaz, A. Fernandez and R. Torrecillas: J. Eur. Ceram. Soc. 2016, vol. 36, pp. 2149-52.

17. U. Schmitt-Radloff, F. Kern and R. Gadow: J. Eur. Ceram. Soc. 2018, vol. 38, pp. 3585-94.

18. D. Sun, X. Jiang, L. Su, H. Sun, C. Hu, T. Song and Z. Luo: Ceram. Int. 2020, vol. 46, pp. 20068-80.

Z.D.I. Sktani, N.A. Rejab, A.F.Z. Rosli, A. Arab and Z.A. Ahmad: J. Rare Earth. 2020. https://doi.org/10.1016/j.jre.2020.06.005.

20. Z. Yin, J. Yuan, C. Huang, Z. Wang, L. Huang and Y. Cheng: Ceram. Int. 2016, vol. 42, pp. 1982-89.

21. J. Deng, H. Zhang, Z. Wu, Y. Lian, Y. Xing and S. Li: Int. J. Refract. Met. H. 2012, vol. 35, pp. 17-26.

22. Z.K. Huang, A. Rosenflanz and I.W. Chen: J. Am. Ceram. Soc. 1997. vol 80: pp. 1256-1262.

23. T. Uhlířová, and W. Pabst: J. Eur. Ceram. Soc. 2020. 40(8): p. 3181-90.

24. Y. Shinoda, Y. Suzuki and K. Yoshida: J. Asian Ceram. Soc., 2013. vol 1, pp. 267-73.

Rahaman, M.N., Ceramic Processes and Sintering. Second edition, Marcel Dekker, New York, 2003.

26. N. Bamba, Y. Choa, T. Sekino and K. Niihara: J. Eur. Ceram. Soc. 1998. vol 18, pp. 693-699.

27. K. Ahmad and W. Pan: Metall. Trans. A 2014, vol. 45, pp. 6271-6276.

28. A.A. Mahday, M.S. Eskandarany, H.A. Ahmed and A.A. Amer: J. Alloys Compd. 2000, vol. 299, pp. 244-53.

29. D. Hong, Z. Yin, S. Yan and W. Xu: Ceram. Int. 2019, vol. 45, pp. 11826-32.

30. H. Manshor, S.M. Aris, A.Z.A. Azhar, E.C. Abdullah and Z.A. Ahmad: Ceram. Int. 2015, vol. 41, pp. 3961-67.

31. R. Kumar, A.K. Chaubey, S. Bathula, B.B. Jha and A. Dhar: Int. J. Refract. Met. H. 2016, vol. 54, pp. 304-08.

32. F. Qi, Z. Wang, J. Wu, H. Xu, J. Kou and L. Zhang: Ceram. Int. 2017, vol. 43, pp. 10691-97.

33. Yin, Z., et al., Mater. Sci. Eng. A, 2013. 577: pp. 9-15.

Y.T. O, J.B. Koo, K.J. Hong, J.S. Park and D.C. Shin: Mater. Sci. Eng. A 2004, vol. 374, pp. 191–95.

35. Y.F. Zhang, L.J. Wang, W. Jiang, G.Z. Bai and L.D. Chen: Mater. Trans. 2005, vol. 46, pp. 2015-19.

36. I. Hussainova, N. Voltšihhin, E. Cura and S.P. Hannula: Mater. Sci. Eng. A 2014, vol. 597, pp. 75-81.

37. Y.H. Fei, C.Z. Huang, H.L. Liu and B. Zou: Ceram. Int. 2014, vol. 40, pp. 10205-09.

38. X.P.Zhang, J.H. Ouyang, Y.J. Wang, Z.G. Liu and Y.M. Wang: J. Mater. Eng. Perform. 2015, vol. 24, pp. 3615-21.

39. J.X. Deng, T.K. Cao, Z.L. Ding, J.H. Liu, J.L. Sun and J.L. Zhao: J. Eur. Ceram. Soc. 2006, vol. 26, pp. 1317-23.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China under Grant Nos. 11805245 and 11505247, the Strategic Priority Research Program of the Chinese Academy of Sciences under Grant No. XDA21010202, the Joint Funds of the National Natural Science Foundation of China under Grant No. U1832206 and Sichuan Science and Technology Program under Grant No. 2018JZ0014.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 6, 2020; accepted December 3, 2020.

Rights and permissions

About this article

Cite this article

Zhu, Y., Chai, J., Shen, T. et al. Mechanical and Friction Properties of Al2O3-ZrO2-TiC Composite with Varying TiC Contents Fabricated by Spark Plasma Sintering. Metall Mater Trans A 52, 767–775 (2021). https://doi.org/10.1007/s11661-020-06122-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06122-3