Abstract

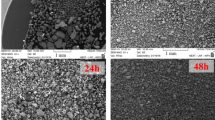

Tribaloys are Laves phases-hardened cobalt alloys usually produced by casting. In order to obtain a finer and more homogeneous microstructure, powder metallurgy was used by gas atomization of T400 Tribaloy powders followed by either spark plasma sintering (SPS) or hot isostatic pressing (HIP). Quantitative characterization of the microstructure was performed with X-ray diffraction, electron microscopy combined with energy-dispersive X-ray spectroscopy, at all stages of the processes. The gas atomized powder presents a fine composite microstructure composed of eutectic Laves phases and cobalt solid solution. The fraction of Laves phases increases upon consolidation time and temperature, with a composition tending to Co3Mo2(Si + Cr). This results in a hardness between 60 and 62 HRC for Spark Plasma Sintered and Hot Isostatic Pressed parts, depending on the consolidation parameters. The high solidification rates of atomization combined with powder consolidation lead to a fine-grained alloy, more homogeneous than cast alloys for the same grades.

Similar content being viewed by others

References

I. Hutching, P. Shipway, Tribology : Friction and Wear of Engineering Materials, 2nd Edition, Butterworth-Heinemann, Oxford, 2016

Bolellia, V. Cannilloa, L. Lusvarghia, M. Montorsia, F. P. Mantinia, M. Barletta, Wear, 2007, vol. 263, pp. 1397–1416,

T. Sahraoui, H.I. Feraoun, N. Fenineche, G. Montavon, H. Aourag, and C. Coddet, Materials Letters, 2004, vol. 58(19), pp. 2433 – 2436

J. Y. Cho, S. H. Zhang, T. Y. Cho, J. H. Yoon, Y. K. Joo, S. K. Hur, J Mater Sci, 2009, vol. 44, pp. 6348–6355

Hoganas. https://www.hoganas.com/globalassets/media/sharepoint-documents/brochuresanddatasheetsalldocuments/powder_choice_with_ease.pdf, 2018.

Kennametal. https://www.kennametal.com/en/products/powdered-materials-and-equipment/thermal-spray-powders.html, 2018.

K. Jiang, R. Liu, K. Chen, and M. Liang, Wear, 2013, vol. 307, pp. 22 – 27.

A. Frenk and W. Kurz. Microstructural effects on the sliding wear resistance of a cobalt-based alloy. Wear, 1994, vol. 174, pp. 81–91.

C.D. Opris, R. Liu, M.X. Yao, and X.J. Wu, Materials and Design, 2007, vol. 28, pp. 581-591.

M.A. Ashworth, J. Bryar, M.H. Jacobs, and S. Davies, Powder Metallurgy, 1999, vol. 42, pp. 243–249.

A. Halstead and R. D. Rawlings, Journal of Materials Science, 1985, vol. 20, pp. 1248–1256.

E. Ström, J. Zhang, S. Eriksson, C. Li, and D. Feng, Materials Science and Engineering: A, 2002, vol. 329-331, pp. 289 – 294.

R. Liu, W. Xu, M.X. Yao, P.C. Patnaik, and X.J. Wu, Scripta Materialia, 2005, vol. 53, pp.1351 – 1355.

W. Xu, Master’s thesis, Carleton Universtiy, 2005.

F. S. Georgette and J. A. Davidson, Journal of Biomedical Materials Research, 1986, vol. 20, pp. 1229–1248.

T. J. J. Jacobs, R. M. Latanision, T. R. M. Rose, and S. J. Veeck, Journal of Orthopaedic Research, 1990, vol. 8, pp. 874–882.

J. Haan, M. Asseln, M. Zivcec, J. Eschweiler, R. Radermacher, and C. Broeckmann, Powder Metallurgy, 2015, vol. 58, pp. 161.

B Patel, F Inam, M Reece, M Edirisinghe, W Bonfield, J Huang, and A Angadji, Journal of the Royal Society Interface, 2010, vol. 7, pp. 1641–1645.

Q. Meng, S. Guo, X. Zhao, S.Veintemillas-Verdaguer, Journal of Alloys and Compounds, 2013, vol. 580, pp. 187–190

W. Xu, R. Liua, P.C. Patnaik, M.X. Yao, and X.J. Wu, Materials Science and Engineering A, 2007, vol 452, pp. 427–436.

Acknowledgments

X. Boulnat thanks S. Cottrino and F. Mercier for their help in performing high-temperature consolidations of the powders.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 26, 2019.

Rights and permissions

About this article

Cite this article

Boulnat, X., Lafont, C., Coudert, JB. et al. Microstructure Evolution of Fine-Grained Cobalt T400 Tribaloy Processed by Spark Plasma Sintering or Hot Isostatic Pressing of Gas-Atomized Powders. Metall Mater Trans A 51, 5318–5327 (2020). https://doi.org/10.1007/s11661-020-05962-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05962-3