Abstract

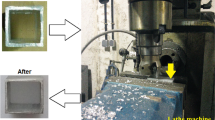

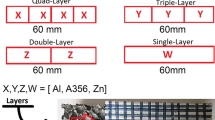

This article investigates the low-velocity impact behavior and crashworthiness of metallic foams and functionally graded foam-filled tubes (FGFTs). Closed cell Zn, Al, and A356 alloy foams fabricated by the direct foaming method are used as axial grading fillers for the manufacture of single-, double-, triple-, and quad-layer structures. The microstructural examinations are implemented by an optical microscope and a field emission scanning electron microscope. The drop-weight impact testing is performed on the metallic foams and FGFTs with a free fall velocity of 5.42 m/s and energy of 294.3 J. The influence of material, density, number, and arrangement of foam layers on the deformation behavior and specific energy absorption (SEA) is studied. The results indicate the multiple crushing response and stepwise increment of stress through distinct plateau regions in the FGFTs. The A356 foam with low density and great inherent strength provides the highest SEA, whereas high density and brittle matrix of the Zn foam deteriorate the SEA of FGFTs. The maximum SEA of 261 J/(g cm−3) is achieved in the double-layer A356-Al foam-filled tube. The best crashworthiness is fulfilled in multilayer A356-Al structures owing to a combination of high SEA and low peak crushing strength (σpeak).

Similar content being viewed by others

References

1.Z. Li, R. Chen, and F. Lu: Thin Walled Struct., 2018, vol. 124, pp. 343-49.

2.I. Duarte, L.K. Opara, and M. Vesenjak: Compos. Struct., 2018, vol. 192, pp. 184-92.

Y. Hangai, R. Yamaguchi, S. Takahashi, T. Utsunomiya. O. Kuwazuru, and N. Yoshikawa (2013) Metall. Mater. Trans. A, vol. 44A, pp. 1880-86.

4.W. Zhao, S.Y. He, Y. Zhang, C. Zhang, G.Y. Tang, and G. Dai: Mater. Lett., 2020, vol. 266, pp. 1-4.

5.M.A. Islam, M.A. Kader, O.J. Hazell, J.P. Escobedo, A.D. Brown, and M. Saadatfar: Mater. Des., 2020, vol. 191, pp. 1-8.

6.B.H.G. Jigh, H.H. Toudeshky, and M.A. Farsi: J. Alloys Compd., 2017, vol. 695, pp. 133-41.

7.M.A. Islam, A.D. Brown, P.J. Hazell, M.A. Kader, J.P. Escobedo, M. Saadatfar, S. Xu, D. Ruan, and M. Turner: Int. J. Impact Eng., 2018, vol. 114, pp. 111-22.

8.M. Vesenjak, M.A. Sulong, L.K. Opara, M. Borovinsek, V. Mathier, and T. Fiedler: Mech. Mater., 2016, vol. 93, pp. 96-108.

9.B.Y. Su, C.M. Huang, H. Sheng, and W.Y. Jang: Mater. Charact., 2018, 135, pp. 203-13.

10.X. Lijun, and S. Weidong: Int. J. Impact Eng., 2018, vol. 111, pp. 255-72.

11.S. Sahu, D.P. Mondal, J.U. Cho, M.D. Goel, and M.Z. Ansari: Composites Part B, 2019, vol. 160, pp. 394-401.

12.Y. Sun, and Q.M. Li: Int. J. Impact Eng., 2018, vol. 112, pp. 74-115.

13.M.A. Kader, A.D. Brown, P.J. Hazell, V. Robins, J.P. Escobedo, and M. Saadatfar: Int. J. Impact Eng., 2020, vol. 139, pp. 1-17.

14.J. Fang, Y. Gao, X. An, G. Sun, J. Chena, and Q. Li: Composites Part B, 2016, vol. 92, pp. 338-49.

15.F. Xiong, D. Wang, and S. Yin: Mater. Des., 2018, vol. 156, pp. 198-214.

16.D.K. Rajak, N.N. Mahajan, E. Linul: J. Alloys Compd., 2019, vol. 775, pp. 675-89.

17.X. Yang, T, An, Z. Wu, T. Zou, H. Song, J. Sha, C. He, and N. Zhao: Compos. Struct., 2020, vol. 245, 112357.

Y. Zhang, X.Y. Zang, K. Wang, S.Y He, J.G Liu, W. Zhao, X.L. Gong, and J. Yu (2020) Mater. Lett. vol. 264, 127292.

S.Y. He, Y.N. Lv, S.T. Chen, G. Dai, J.G. Liu, and M.K. Huo (2020) Mater. Sci. Eng. A, vol. 772, pp. 1-12.

20.Y. Duan, X. Zhao, Z. Liu, N. Hou, H. Liu, B. Du, B. Hou, and Y. Li: Composites Part B, 2020, vol. 183, 107630.

21.Y. Duan, X. Zhao, B. Du, X. Shi, H. Zhao, B. Hou, and Y. Li: Int. J. Mech. Sci., 2020, vol. 177, pp. 1-14.

Y. Hangai, N. Kubota, T. Utsunomiya, H. Kawashima, O. Kuwazuru, and N. Yoshikawa: Mater. Sci. Eng. A, 2015, vol. 639, pp. 597-603.

J. Zhang, L. Chen, H. Wu, Q. Fang, and Y. Zhang (2020) Compos. Struct., vol. 241, pp. 1-12.

24.M.S. Attia, S.A. Meguid, and H. Nouraei: Finite Elem. Anal. Des., 2012, vol. 61, pp. 50-59.

25.H. Yin, G. Wen, S. Hou, and Q. Qing: Mater. Des., 2013, vol. 44, pp. 414-28.

Y. Zhang, S.Y. He, J.G Liu, W. Zhao, X.L Gong, and J. Yu (2019) Compos. Struct. vol. 220, pp. 451-59.

27.X. Yu, Q. Qin, J. Zhang, S. He, C. Xiang, M. Wang, and T.J. Wang: Compos. Struct., 2018, vol. 201, pp. 423-33.

28.G. Li, Z. Zhang, G. Sun, F. Xu, and X. Huang: Int. J. Mech. Sci., 2014, 89, pp. 439-52.

29.O. Mohammadiha, and H. Ghariblu: Thin Walled Struct., 2016, vol. 98, pp. 627-39.

30.M. Salehi, S.M.H. Mirbagheri, and M. Arabkohi: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 5494-5509.

31.N. Movahedi, S.M.H. Mirbagheri, and S.R. Hosseini: Met. Mater. Int., 2014, vol. 20, pp. 757-63.

32.A. Baroutaji, M. Sajjia, and A.G. Olabi: Thin Walled Struct., 2017, vol. 118, pp. 137-63.

33.M. Li, J. Li, S. Barbat, R. Baccouche, and W. Lu: Compos. Struct., 2018, vol. 200, pp. 120-26.

34.M. Li, S. Barbat, R. Baccouche, J. Belwafa, W. Lu: Composites Part B, 2020. vol. 193, pp. 1-10.

35.G. Sun, T. Liu, X. Huang, G. Zheng, and Q. Li: Eng. Struct., 2018, vol. 155, pp. 235-50.

36.M.J. Rezvani, and H. Souzangarzadeh: J. Storage Mater., 2020, vol. 27, 101071.

37.G. Zhu, S. Li, G. Sun, G. Li, and Q. Li: Thin Walled Struct., 2016, vol. 109, pp. 377-89.

J. Fan, J. Zhang, Z. Wang, Z. Li, and L. Zhao: Mater. Sci. Eng. A, 2013, vol. 561, pp. 352-61.

39.L.J. Gibson, and M.F. Ashby: Cellular Solids: Structure and Properties, 2nd ed., Cambridge Solid State Science Series, London, 1997, pp. 175-231.

40.X. Zhou, Y. Li, and X. Chen: J. Mater. Process. Technol., 2020, vol. 283, pp. 1-11.

I. Cantat, S.C. Addad, F. Elias, F. Graner, R. Hohler, O. Pitois, F, Rouyer, and A. Saint-Jalmes (2013) Foams Structure and dynamics. 1st edn. Oxford University Press, London. pp. 17-30.

42.M. Mukherjee, F.G. Moreno, C. Jimenez, A. Rack, and J. Banhart: Acta Mater., 2017, vol. 131, pp. 156-68.

43.J.Y. Yuan, and Y.X. Li: Trans. Nonferrous Met. Soc. China, 2015, vol. 25, pp. 1619-25.

44.J.W. Ming, F.Z. Tian, and L.D. Jun: Trans. Nonferrous Met. Soc. China, 2012, vol. 22, pp. 7-13.

45.ASM Handbook Committee: Metals Handbook, 2nd ed., vol. 3, Alloy phase diagrams, ASM International, Materials Park, Ohio, 1990.

46.G. E. Dieter, Mechanical Metallurgy, 3rd ed., McGraw-hill Education, New York, 1986, pp. 81-95.

47.U.A. Atturan, S.H. Nandam, B.S. Murty and S. Sankaran: Mater. Sci. Eng. A, 2017, vol. 684, pp. 178-85.

R. Huang, S. Ma, M. Zhang, J. Xu, and Z. Wang: Mater. Sci. Eng. A, 2019, vol. 756, pp. 302-13.

D. Ruan, G. Lu. F.L. Chen, and E. Siores (2002) Compos. Struct., vol. 56, pp. 331-36.

50.J. Shen, G. Lu, and D. Ruan: Composites Part B, 2019, vol. 41, pp. 678-85.

51.T. Dirgantara, A. Jusuf, E.O. Kurniati, L. Gunawan, and I..S. Putra: Thin Walled Struct., 2018, vol. 129, pp. 365-80.

52.Y. Hangai, S. Otazawa, and T. Utsunomiya: Compos. Struct., 2018, vol. 183, pp. 416-22.

53.C. Ge, Q. Gao, L. Wang, and Z. Hong: Thin Walled Struct., 2020, vol. 149, pp. 1-10.

Y. Hangai, H. Ikeda, K. Amagai, R. Suzuki. M. Matsubara, and N. Yoshikawa (2018) Metall. Mater. Trans. A, vol. 49A, pp. 4452-55.

Y. Hangai, T. Morita, and T. Utsunomiya: Mater. Sci. Eng. A, 2017, vol. 696, pp. 544-51.

56.Y. Hangai, Y. Oba, S. Koyama, and T. Utsunomiya: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3585-89.

57.B. Koohbor, and A. Kidane: Int. J. Mech. Sci., 2013, vol. 68, pp. 151-61.

58.L. Maheo, and P. Viot: Int. J. Impact Eng., 2013, vol. 53, pp. 84-93.

59.N. Gardner, E. Wang, and A. Shukla: Compos. Struct., 2012, vol. 94, pp. 1755-70.

60.X. Zhang, and H. Zhang: Mater. Des., 2016, vol. 102, pp. 199-211.

61.X. Liu, J. Zhang, Q. Fang, H. Wu, and Y. Zhang: Int. J. Impact Eng., 2016, vol. 110, pp. 382-94.

62.Q. Fang, J. Zhang, Y. Zhang, J. Liu, and Z. Gong: Compos. Struct., 2015, vol. 124, pp. 409-20.

63.M.J. Nayyeri, and S.M.H. Mirbagheri: Mater. Lett., 2016, vol. 185, pp. 89-91.

Acknowledgments

This work was supported by the Metal Foam Group of Amirkabir University (MFGAU) through Grant No. 110-mir-13980131.The authors are grateful to Rahyaft Advanced Sciences and Technologies, a knowledge-based company, for their support in casting the metal foams.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 29, 2020.

Rights and permissions

About this article

Cite this article

Salehi, M., Mirbagheri, S.M.H. & Ramiani, A.J. Deformation Behavior and Crashworthiness of Functionally Graded Metallic Foam-Filled Tubes Under Drop-Weight Impact Testing. Metall Mater Trans A 51, 5120–5138 (2020). https://doi.org/10.1007/s11661-020-05928-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05928-5