Abstract

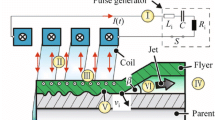

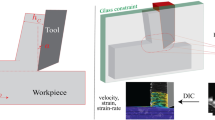

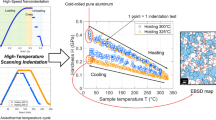

The National Institute of Standards and Technology (NIST) has developed an electrical pulse-heated Kolsky Bar technique for measuring the constitutive response of metals at heating rates of up to 6,000 K/s and strain rates up to 104 s−1. Under these conditions, which are approaching those found in high speed machining, thermally activated microstructural processes such as grain growth, solid state phase transformation and dislocation annealing can be bypassed, leading to unique non-equilibrium superheated microstructural states. Flow stresses can thus differ significantly from equilibrium high temperature conditions. This paper describes the NIST pulse-heated Kolsky bar technique in detail, including a thorough assessment of uncertainties in temperature and flow stress measurement.

Similar content being viewed by others

Notes

Commercial products are identified in this work to adequately specify certain procedures. In no case does such identification imply recommendation or endorsement by NIST, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose.

References

Kalpakjian S (1991) Manufacturing processes for engineering materials, 2nd edn. Addison-Wesley, Reading, MA, USA.

Gray GT III (1990) Classic split-Hopkinson pressure bar testing. ASM Handbook 8:462–476. Materials Park, Ohio.

Basak D, Yoon HW, Rhorer R, Burns TJ, Matsumoto T (2004) Temperature control of pulse heated specimens in a Kolsky Bar apparatus using microsecond time-resolved pyrometry. Int J Thermophys 252:561–574.

Frost HJ, Ashby MF (1982) Deformation mechanism maps: the plasticity and creep of metals and ceramics. Pergamon, New York.

Lindholm US, Yeakley LM (1968) High strain-rate testing: tension and compression. Exp Mech 8:1–9.

DeWitt DP, Nutter GD (1988) Theory and practice of radiation thermometry. Wiley, New York.

Lifshitz JM, Leber H (1994) Data processing in the split Hopkinson pressure bar tests. Int J Impact Eng 156:723–733.

Bertholf LD, Karnes KH (1975) Two-dimensional analysis of the split Hopkinson pressure bar system. J Mech Phys Solids 23:1–19.

Hild F, Roux S (2006) Digital image correlation: from displacement measurement to identification of elastic properties—a review. Strain 42:69–80.

Chen W, Song B, Frew DJ, Forrestal MJ (2003) Dynamic small strain measurements of a metal specimen with a split Hopkinson pressure bar. Exp Mech 43:20–23.

Davies EDH, Hunter SC (1963) The dynamic compression testing of solids by the method of the split-Hopkinson pressure bar. J Mech Phys Solids 11:155–179.

Hertzberg RW (1989) Deformation and fracture mechanics of engineering materials, 3rd edn. Wiley, New York, p 21.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mates, S.P., Rhorer, R., Whitenton, E. et al. A Pulse-Heated Kolsky Bar Technique for Measuring the Flow Stress of Metals at High Loading and Heating Rates. Exp Mech 48, 799–807 (2008). https://doi.org/10.1007/s11340-008-9137-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9137-1