Abstract

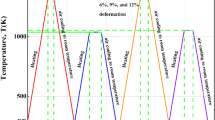

The polycrystalline elastic constants of an indigenous variant of 9Cr-1W-based reduced activation ferritic-martensitic (RAFM) steel have been determined as a function of temperature from 298 K to 1323 K (25 °C to 1000 °C), using impulse excitation technique (IET). The three elastic constants namely, Young’s modulus E, shear modulus G, and bulk modulus B, exhibited significant softening with increasing temperature, in a pronounced non-linear fashion. In addition, clearly marked discontinuities in their temperature variations are noticed in the region, where ferrite + carbides → austenite phase transformation occurred upon heating. Further, the incidence of austenite → martensite transformation upon cooling has also been marked by a step-like jump in both elastic E and shear moduli G. The martensite start Ms and Mf finish temperatures estimated from this study are, Ms = 652 K (379 °C) and Mf =580 K (307 °C). Similarly, the measured ferrite + carbide → austenite transformation onset (Ac1) and completion (Ac3) temperatures are found to be 1126 K and 1143 K (853 °C and 870 °C), respectively. The Poisson ratio μ exhibited distinct discontinuities at phase transformation temperatures; but however, is found to vary in the range 0.27 to 0.29. The room temperature estimates of E, G, and μ for normalized and tempered microstructure are found to be 219 GPa, 86.65 GPa, and 0.27, respectively. For the metastable austenite phase, the corresponding values are: 197 GPa, 76.5 GPa, and 0.29, respectively. The measured elastic properties as well as their temperature dependencies are found to be in good accord with reported estimates for other 9Cr-based ferritic-martensitic steel grades. Estimates of θ elD , the elastic Debye temperature and γG, the thermal Grüneisen parameter obtained from measured bulk elastic properties are found to be θ elD = 465 K (192 °C) and γG = 1.57.

Similar content being viewed by others

References

G. Grimvall: Thermophysical Properties of Materials, 2nd ed., North-Holland, Elsevier, Amsterdam, 1999, pp. 37-68.

Ledbetter H (1983) Elastic Properties, In: Reed RP, Clark AR (eds) Materials at low temperatures American Society of Metals, Metals Park, pp. 1-45.

Ledbetter H (2006) Mater. Sci. Eng, A, 442:31-34.

A. Migliori, J. P. Baiardo and T. W. Darling: Los Alamos Science, 2000, No. 26, pp. 208-225.

Y. Wang, J. J. Wang, H. Zhang, V. R. Manga, S. L. Shang, L -Q Chen, Z-K Liu: J. Phys 2010, 22:1-8

D. C. Wallace: Statistical Physics of Crystals and Liquids, World Scientific Pub., Singapore, 2002, pp. 1-303.

Stixrude L (2001) Microscopic Theory of Elastic Constants Handbook of Elastic Properties of Solids, Liquids, and Gases. In: Levy M, Bass H, Stern R (eds.) Vol II: Elastic Properties of Solids. Academic Press, Boston, pp. 640-671.

Y. Ikeda: Mater. Trans. JIM, 1997, Vol. 38, pp.761-770.

Mehl MJ, Klein BM, Papaconstantopoulos DA (1994) First Principles Calculation of Elastic Properties. In: J. H. Westbrook and R. L. Fleischer (eds) Intermetallic Compounds, Vol. I: Principles. John Wiley, Chichester, pp. 195-210.

Anderson OL (1995) Equations of State for Solids in Geophysics and Ceramic Science. Oxford University Press, New York, pp. 1-383.

S. Raju and A. K. Rai: J. Nucl. Mater., 2010, Vol. 408, pp.40-44.

S. Raju, K. Sivasubramanian and E. Mohandas: Scripta Mater., 2001, Vol. 44 pp. 269-274.

S. Raju, K. Sivasubramanian and E. Mohandas: Solid St. Commun., 2002, Vol. 124, pp. 151–156.

Michel H. G. Jacobs and Harry A. J. Oonk: Phys. Chem. Chem. Phys., 2000, Vol. 2, pp. 2641-2646.

G. Simmons and H. Wang: Single crystal elastic constants and calculated aggregate properties: A handbook, II edition, 1971, MIT Press, Cambridge, Mass, pp.1-370.

Hearmon RFS (1979) Landolt Bornstein Numerical Data and Functional Relationships in Science and Technology. In: Hellwege K-H (ed) Elastic, Piezoelectric, Pyroelectric, Piezooptic, Electrooptic Constants, and Nonlinear Dielectric Susceptibilities of Crystal. Springer, Berlin, pp. 1–244.

H. Wawra: Zeit. fur Metallkunde, 1978, Vol. 69, pp. 518-523.

Isaak DG (2001) Elastic properties of minerals and planetary objects. In: Levy M, Bass H, Stern R (eds) Handbook of Elastic Properties of Solids, Liquids, and Gases Volume III: Biological and Organic Materials Earth and Marine Sciences. Academic Press, Boston, pp. 325-376.

G. R. Speich, A. J. Schwoeble and W. C. Leslie: Metall. Trans., 1972, Vol.3, pp. 2031-2037.

Ledbetter H, Kim S (2001) Monocrystal Elastic Constants and Derived Properties of the Cubic and the Hexagonal Elements. In: In: Levy M, Bass H, Stern R (eds) Handbook of Elastic Properties of Solids Liquids and Gases Volume II: Elastic Properties of Solids. Academic Press, Boston, pp. 97-106.

Hassel Ledbetter: Cryogenics, 1982, Vol. 22, pp. 653-656.

W. F. Weston, H. M. Ledbetter and E. R. Naimon: Mater. Sci. Engg,.1975, Vol. 20, pp. 185-194.

H. M. Ledbetter, M. W. Austin and S. A. Kim: Mater. Sci. Engg., 1987, Vol.85, pp. 85-89.

Ulrich Bohnenkamp and Rolf Sandstrom: Steel Res., 2000, Vol. 71, pp. 94-99.

T. Darling, A. Migliori, P.E. Armstrong, R. Vaidya, C. Scherer and T. Lowe: Reports on the measurement of elastic properties of 51XX series of steels for the heat treatment distortion project, Los Alamos Report, LA-UR-97, 1997, pp. 1–64.

S. Sharafat, G.R. Odette and J. Blanchard: J. Nucl. Mater., 2009, Vol. 386-388, pp.896–899.

K. Laha, S. Saroja, A. Moitra, R. Sandhya, M. D. Mathew, T. Jayakumar and E. Rajendra Kumar: J. Nucl. Mater., 2013, Vol. 439, pp. 41-50.

N. Baluc, R. Schäublin, P. Spätig and M. Victoria: Nucl. Fusion, 2004, Vol. 44, pp. 56-61.

S. Raju, B. Jeyaganesh, A. K. Rai, R. Mythili, S. Saroja, E. Mohandas, M. Vijayalakshmi, K. B. S. Rao and Baldev Raj: J. Nucl. Mater., 2009, Vol. 389, pp. 385-393.

S. Raju, B. Jeyaganesh, A. K. Rai, R. Mythili, S. Saroja and Baldev Raj: J. Nucl. Mater., 2010, Vol. 405, pp.59–69.

Ravi Kirana, S Raju, R Mythili, S Saibaba, T Jayakumar, and E Rajendra Kumar: Steel Res., 2015, Vol. 86, pp. 825-840.

Ravikirana, R. Mythili, S Raju, S Saroja, G. Paneerselvam, T Jayakumar and E. Rajendra Kumar: Bull. Mater. Sci., 2014, Vol. 37, pp.1453-1460.

S. Raju, B. Jeyaganesh, A. K. Rai, S. Saroja, E. Mohandas, M. Vijayalakshmi, and Baldev Raj: Int. J. Thermophys., 2010, Vol.31, pp. 399-415.

S. Raju, H. Tripathy, A. K. Rai, R. N. Hajra, S. Saroja, T Jayakumar and E. Rajendra Kumar: J. Nucl. Mater., 2015, Vol. 459, pp.150–158.

M. D. Mathew, J. Vanaja, K. Laha, G. Varaprasad Reddy, K. S. Chandravathi and K. Bhanu Sankara Rao: J. Nucl. Mater., 2011, Vol. 417, pp.77-80.

R. Sandhya, Vani Shankar, K. Mariappan, M. D. Mathew, T. Jayakumar and E. Rajendra Kumar, Adv. Mater. Res., 2014, Vol. 891-892, pp. 383-388.

A. Moitra, A. Das Gupta, S. Sathyanarayanan, G. Sasikala, S. K. Albert, S. Saroja, A. K. Bhaduri, E. Rajendra Kumar and T. Jayakumar: Procedia Engineering, 2014, Vol. 86, pp.258-263.

G. Roebben, B. Bollen, A. Brebels, J. Van Humbeeck and O. Van der Biest: Rev. Sci. Instrum., 1997, Vol. 68, pp. 4511-4515.

G. Roebben, R.–G. Duan, D. Sciti and O. Van der Biest: J. Euro Ceram Soc., 2002, Vol. 22, pp. 2501-2509.

W. Pabst, E. Gregorova and M. Cerny: J. Euro Ceram Soc., 2013, Vol. 33, pp. 3085-3093.

J. D. Lord and R. Morrell: NPL Measurement Good Practice Guide: Elastic Modulus Measurement, NPL Report, 2006, Teddington, U. K., pp. 1-98.

M. Radovic, E. Lora-Curzio and L. Riester: Mater. Sci. Engg. A, 2004, Vol. 368, pp.56-70.

Javier Etcheverry, Gustavo Sanchez, Nicholas Bonades and Leandro Iglesias Raggu: IV Congresso Iberoamericano de Acoustica, 2008, FIA A025, pp.1-5.

A. K. Swarnakar, S. Giménez, S. Salehi, J. Vleugels and O. Van der Biest: Key Engg. Mater., 2007, Vol. 333, pp.235-238.

A. Brebels and B. Bollen: Non destructive evaluation of materials properties as a function of temperature, in: NDE India-2014, Conference Proceedings, 2015, Vol. 20, No.6, pp. 1–10.

ASTM E1876-15: Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration, 2015, ASTM International, West Conshohocken, PA, pp. 1-17.

ASTM C1259-15: Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio for Advanced Ceramics by Impulse Excitation of Vibration, 2015, ASTM International, West Conshohocken, PA, pp. 1-17.

Jeyaganesh B, Raju S, Rai AK, Mohandas E, Vijayalakshmi M, Rao ABS, Raj B (2011) Mater. Sci. Tech. 27:500-512.

Hong–Seok Yang and H. K. D. H. Bhadeshia: Scripta Mater., 2009, Vol. 60, pp. 493-495.

Cast´an T, Vives E, Planes A (1990) J. Phys. 2:1743-1752.

Hidenori Terasaki, Hideki Yamagishi, Koji Moriguchi, Yusaku Tomio and Yu-ichi Komizo, ISIJ Int., 2011, Vol.51, pp. 1566-1568.

Bhadeshia H, Honeycombe R (2017) Steels: Microstructure and Properties. 4th edition. Elsevier, London.

A.-A. F. Tavassoli, J.-W. Rensman, M. Schirra and K. Shiba: Fusion Eng. & Design, 2002, Vol. 61-62, pp. 617-628.

Yin YF, Faulkner RG (2008) Physical and elastic properties of creep resistant steels. In: Abe F, Kern T-U, Viswanathan R (eds.) Creep-resistant steels. Woodhead Pub Co, Cambridge, pp. 217-240.

K. Haarmann, J. C. Vaillant, B. Vandenberghe, W. Bendick and A. Arbab: The T91/P91 Book, 2002, Vallourec and Mannesmann tubes, Boulogne.

Richardot D, Vaillant JC, Arbab A, Bendick W (2000) The T92/P92 book. Vallourec & Mannesmann tubes, Boulogne.

K. Sawada, T. Ohba, H. Koshima and K. Kimura: Mater. Sci. Engg. A, 2005, Vol. 394, pp. 36-42.

B. A. Latella and S. R. Humphries: Scripta Metall., 2004, Vol. 51, pp. 635-639.

Kim SA, Johnson WL (2007) Mater. Sci. Engg. A 452-453:633-639

G. R. Speich and W. C. Leslie: Metall. Trans., 1973, Vol.4, pp. 1873-1875.

S. Raju, B. Jeyaganesh, A. Banerjee and E. Mohandas: Mater. Sci. Eng. A, 2007, Vol. 465, pp. 29-37.

H. Ledbetter: Phys. Stat. Solidi B, 1994, Vol. 181, pp. 81-85.

S. Raju and A. K. Rai: J. Nucl. Mater., 2011, Vol. 408, pp. 40-44.

Acknowledgments

The authors acknowledge Dr. Bart Bollen in educating us on the technical nuances of IET technique, as adapted in IMCE RFDA equipment. The continued support and encouragement offered by Dr. A. K. Bhaduri, Director, IGCAR and Dr. G. Amarendra, Director, Metallurgy and Materials Group, IGCAR are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 14, 2017.

Rights and permissions

About this article

Cite this article

Tripathy, H., Raju, S., Hajra, R.N. et al. High Temperature Elastic Properties of Reduced Activation Ferritic-Martensitic (RAFM) Steel Using Impulse Excitation Technique. Metall Mater Trans A 49, 979–989 (2018). https://doi.org/10.1007/s11661-017-4449-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4449-3