Abstract

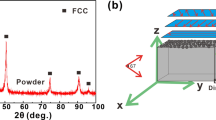

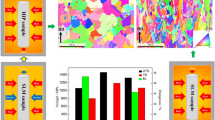

Precipitation hardening copper alloy C70250 was selectively laser melted to successfully produce components around 98 pct dense with high mechanical strength and electrical conductivity. Aging heat treatments were carried out at 723 K (450 °C) directly on as-printed samples up to 128 hours. Mechanical testing found that peak yield strength of around 590 MPa could be attained with an electrical conductivity of 34.2 pct IACS after 8 hours of aging. Conductivity continues to increase with further aging while the peak strength appears to be less sensitive to aging time exhibiting a broad range of time where near-peak properties exist. After aging for 128 hours, there is a drop in yield strength to 546 MPa with an increase in conductivity to 43.2 pct IACS. Electron microscopy analysis revealed nanometer-scale silicon-rich oxide particles throughout the material that persist during aging. Deformation twinning is observed in the peak-age condition after tensile testing and several strengthening mechanisms appear to be active to varying degrees throughout aging which account for the broad range of aging time where nearly the peak mechanical properties exist.

Similar content being viewed by others

Change history

13 November 2017

In the Experimental Methods section, second paragraph, last sentence of the original article the value for the resistivity of pure copper is incorrect. The correct value is 1.7241 µΩ-cm.

References

1. Gibson I, Rosen D, Stucker B (2010) Additive Manufacturing Technologies, 1st ed. Springer, New York, NY, pp. 103-42.

D. Bourell: Annu. Rev. Mater. Res., 2016, vol. 46, pp. 1-18.

M.K. Thompson, G. Moroni, T. Vaneker, G. Fadel, R.I. Campbell, I. Gibson, A. Bernard, J. Schulz, P. Graf, B. Ahuja, and F. Martina: CIRP Ann., 2016, vol. 65, pp. 737-60.

L.E. Loh, C.K. Chua, W.Y. Yeong, J. Song, M. Mapar, S.L. Sing, Z.H. Liu, and D.Q. Zhang: Int. J. Heat Mass Transfer, 2015, vol. 80, pp. 288-300.

L. Thijs, F. Verhaeghe, T. Craeghs, J.V. Humbeeck, and J.P. Kruth: Acta Mater., 2010, vol. 58, pp. 3303–12.

L.E. Murr, E. Martinez, J. Hernandez, S. Collins, K.N. Amato, S.M. Gaytan, and P.W. Shindo: J. Mater. Res. Technol., 2012, vol. 1, pp. 167-77.

E. Yasa and J.P. Kruth: Procedia Eng., 2011, vol. 19, pp. 389–95.

B. Song, X. Zhao, S. Li, C. Han, Q. Wei, S. Wen, J. Liu, and Y. Shi: Front. Mech. Eng., 2015, vol. 10, pp. 111–25.

L. Thijs, K. Kempen, J.P. Kruth, and J.V. Humbeeck: Acta Mater., 2013, vol. 61, pp. 1809–19.

B. Vrancken, L. Thijs, J.P. Kruth, and J.V. Humbeeck: J. Alloys Compd., 2012, vol. 541, pp. 177–85.

11. Bormann T, Müller B, Schinhammer M, Kessler A, Thalmann P, Wild MD (2014) Mater. Charact. 94:189-202

T.T. Roehling, S.S.Q. Wu, S.A. Khairallah, J.D. Roehling, S.S. Soezeri, M.F. Crumb, and M.J. Matthews: Acta Mater., 2017, vol. 128, pp. 197-206.

J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang, and X. Zeng: Mater. Des., 2016, vol. 108, pp. 308-18.

A.A. Antonysamy, J. Meyer, and P.B. Prangnell: Mater. Charact., 2013, vol. 84, pp. 153-68.

J.R. Davis: Copper and Copper Alloys, 1st ed., ASM International, Materials Park, OH, 2001.

D.M. Zhao, Q.M. Dong, P. Liu, B.X. Kang, J.L. Huang, and Z.H. Jin: Mater. Chem. Phys., 2003, vol. 79, pp. 81-86.

D. Zhao, Q.M. Dong, P. Liu, B.X. Kang, J.L. Huang, and Z.H. Jin: Mater. Sci. Eng. A, 2003, vol. A361, pp. 93-99.

S.A. Lockyer and F.W. Noble: J. Mater. Sci., 1994, vol. 29, pp. 218-26.

S.A. Lockyer and F.W. Noble: Mater. Sci. Technol., 1999, vol. 15, pp. 1147-53.

T. Hu, J.H. Chen, J.Z. Liu, Z.R. Liu, and C.L. Wu: Acta Mater., 2013, vol. 61, pp. 1210-19.

A.P. Ventura, C.A. Wade, G. Pawlikowski, M. Bayes, M. Watanabe, and W.Z. Misiolek: Metall. Mater. Trans. A, 2017, vol. 48, pp. 178-87.

K. Saeidi, X. Gao, Y. Zhong, and Z.J. Shen: Mater. Sci. Eng. A, 2015, vol. 625, pp. 221-29.

P. Stadelmann, JEMS-SAAS V 4.5028 (2017), http://www.jems-saas.ch. Accessed Feb. 2017.

M. Watanabe and D.B. Williams: J. Microsc., 2006, vol. 221, pp. 89-109.

V.C. Srivastava, A. Schneider, V. Uhlenwinkel, and K. Bauckhage: Mater. Sci. Tech., 2004, vol. 20, pp. 839-48.

J.F. Wang, S.G. Jia, S.H. Chen, K.X. Song, P. Liu, and G.J. Yu: Adv. Mater. Res., 2011, vol. 197-198, pp. 1315-20.

27. Watanabe C, Hiraide H, Zhang Z, Monzen R (2005) J. Soc. Mater. Sci., Jpn. 54:717-23

S.O. Kasap: Principles of Electronic Materials and Devices, 3rd ed., McGraw-Hill, New York, NY, 2006, pp. 113-54.

J. Miyake and M.E. Fine: Acta Metall. Mater., 1992, vol. 40, pp. 733-41.

S. Kou: Welding Metallurgy, 2nd ed., John Wiley & Sons, Inc., Hoboken, NJ, 2003, pp. 145-212.

Y.L. Jia, M.P. Wang, C. Chen, Q.Y. Dong, S. Wang, and Z. Li: J. Alloys Compd., 2013, vol. 557, pp. 147-51.

D.B. Williams and C.B. Carter: Transmission Electron Microscopy: Part 2 Diffraction, 2nd ed., Springer Science+Business Media, LLC, New York, NY, 2009, pp. 277-303.

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys, 3rd ed., Taylor & Francis Group, LLC, Boca Raton, FL, 2009, pp. 140-235.

34. DuPont JN (2011) Welding Fundamentals and Processes, Fundamentals of Weld Solidification. ASM International, Materials Park, OH, vol. 6A, pp. 96-114

T. Boegelein, S.N. Dryepondt, A. Pandey, K. Dawson, and G.J. Tatlock: Acta Mater., 2015, vol. 87, pp. 201-15.

36. Ellingham H (1944) J. Soc. Chem. Ind. Lond. 63:125-60

Z. Sun, X. Tan, S.B. Tor, and W.Y. Yeong: Mater. Des., 2016, vol. 104, pp. 197-204.

S. Semboshi, S. Sato, A. Iwase, and T. Takasugi: Mater. Charact., 2016, vol. 115, pp. 39-45.

S.Z. Han, J. Lee, M. Goto, S.H. Lim, J.H. Ahn, S. Kim, and K. Kim: Philos. Mag. Lett., 2016, vol. 96, pp. 196-203.

D.B. Williams and E.P. Butler: Int. Met. Rev., 1981, vol. 26, pp. 153-83.

T. Gladman: Mater. Sci. Technol., 1999, vol. 15, pp. 30-36.

42. Gladman T (1997) The Physical Metallurgy of Microalloyed Steels. Institute of Materials, London, vol. 615

E. Nembach: Particle Strengthening of Metals and Alloys, 1st ed., John Wiley & Sons, Inc., New York, NY, 1997, pp.63-91.

L.M. Cheng, W.J. Poole, J.D. Embury, and D.J. Lloyd: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2473-81.

W.J. Poole, X. Wang, D.J. Lloyd, and J.D. Embury: Philos. Mag., 2005, vol. 85, pp. 3113-35.

Kelly A, Nicholson RB (1971) Strengthening Methods in Crystals, 1st ed. Applied Science Publishers Ltd, Barking, Essex, GB, 1971, pp. 175-90

U.F. Kocks and H. Mecking: Prog. Mater. Sci., 2003, vol. 48, pp. 171-273.

U.F. Kocks: Strain Hardening and ‘Strain-Rate Hardening. ASTM STP 765, ASTM, 1982, pp. 121–38.

Araki, W.J. Poole, E. Kobayashi, and T. Sato: Mater. Trans., 2014, vol. 55, pp. 501-05

Rohatgi, K.S. Vecchio, and G.T. Gray III: Metall. Mater. Trans. A, 2001, vol. 32, pp. 135-45.

M.A. Meyers, O. Vöhringer, and V.A. Lubarda: Acta Mater., 2001, vol. 49, pp. 4025-39.

Acknowledgments

The authors would like to thank TE Connectivity, ltd. for the funding of this research along with collaboration throughout the study. The authors thank the Loewy Family Foundation for financially supporting this project and two of the authors, (Anthony P. Ventura) as a Loewy Graduate Fellow and (Wojciech Z. Misiolek) through the Loewy Professorship at Lehigh University. Lastly, the authors thank the W. M. Keck Foundation for financial support of Dr. Christopher J. Marvel.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 9, 2017.

A correction to this article is available online at https://doi.org/10.1007/s11661-017-4395-0.

Rights and permissions

About this article

Cite this article

Ventura, A.P., Marvel, C.J., Pawlikowski, G. et al. The Effect of Aging on the Microstructure of Selective Laser Melted Cu-Ni-Si. Metall Mater Trans A 48, 6070–6082 (2017). https://doi.org/10.1007/s11661-017-4363-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4363-8