Abstract

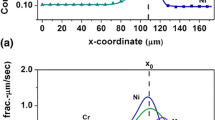

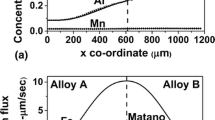

In the present study, diffusion behavior under equilibrium and nonequilibrium conditions in a Fe-C/Ti system is studied in the temperature range of 773 K to 1073 K (500 °C to 800 °C). A defect-free weld joint between mild steel (MS) (Fe-0.14 pct C) and Ti Grade 2 obtained by friction welding is diffusion annealed for various durations to study the interdiffusion behavior under equilibrium conditions, while an explosive clad joint is used to study interdiffusion under nonequilibrium conditions. From the elemental concentration profiles obtained across the MS-Ti interface using electron-probe microanalysis and imaging of the interface, the formation of distinct diffusion zones as a function of temperature and time is established. Concentration and temperature dependence of the interdiffusion coefficients (D(c)) and activation energies are determined. Under equilibrium conditions, the change in molar volume with concentration shows a close match with the ideal Vegard’s law, whereas a negative deviation is observed for nonequilibrium conditions. This deviation can be attributed to the formation of secondary phases, which, in turn, alters the D(c) values of diffusing species. Calculations showed that the D 0 and activation energy for interdiffusion under equilibrium is on the order of 10−11 m2/s and 147 kJ/mol, whereas it is far lower in the nonequilibrium case (10−10 m2/s and 117 kJ/mol) in the compositional range of 40 to 50 wt pct Fe, which also manifests as accelerated growth kinetics of the different diffusion zones.

Similar content being viewed by others

Notes

JMATPRO is a trademark of M/s Sente Software Ltd, UK.

References

A. Ravi Shankar, R.K. Dayal, R. Balasubramaniam, V.R. Raju, R. Mythili, S. Saroja, M. Vijayalakshmi, and V.S. Raghunathan: J. Nucl. Mater., 2008, vol. 327, pp. 277–88.

Baldev Raj and U. Kamachi Mudali: Progr. Nucl. Energy, 2006, vol. 48, pp. 283–313.

U. KamachiMudali, B.M. AnandaRao, K. Shanmugam, R. Natarajan, BaldevRaj: J. Nucl. Mater., 2003, vol. 321, pp. 40–48.

C. Sudha, T.N. Prasanthi, S. Murugesan, S. Saroja, P. Kuppusami, and M. Vijayalakshmi: Sci. Technol. Welding Joining, 2011, vol. 16, pp. 133–39.

T.N. Prasanthi, C. Sudha, P.K. Parida, A. Das Gupta, and S. Saroja: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 1519–36.

M. Ghosh and S. Chatterjee: Mater. Sci. Eng. A, 2003, vol. 358, pp. 152–58.

S. Kundu, S. Chatterjee, D. Olson, and B. Mishra: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 2053–60.

M. Ghosh, K. Bhanumurthy, G.B. Kale, J. Krishnan, and S. Chatterjee: J. Nucl. Mater., 2003, vol. 322, pp. 235–41.

G.B. Kale, K. Bhanumurthy, K.C. Ratnakala, and S.K. Khera: J. Nucl. Mater., 1986, vol. 138, pp. 73–80.

S. Mitra, J.P. Stark, and S.R. Tatti: J. Phys. Chem. Solids, 1991, vol. 52, pp. 463–65.

R.V. Patil, G.B. Kale, and S.P. Garg: J. Nucl. Mater., 1995, vol. 223, pp. 169–73.

K. Bhanumurthy, G.B. Kale, and S.K. Khera: J. Nucl. Mater., 1991, vol. 185, pp. 208–13.

G.B. Kale, R.V. Patil, and P.S. Gawade: J. Nucl. Mater., 1998, vol. 257, pp. 44–50.

A. Laik, K. Bhanumurthy, and G.B. Kale: J. Nucl. Mater., 2002, vol. 305, pp. 124–33.

K. Bhanumurthy, G.B. Kale, S.K. Khera, and M.K. Asundi: J. Nucl. Mater., 1989, vol. 16, pp. 179–83.

G.B. Kale, K. Bhanumurthy, K.C. Ratnakala, and S.K. Khera: J. Nucl. Mater., 1986, vol. 138, pp. 73–80.

F.J.A. Den Broeder: Scripta Metall., 1969, vol. 3, pp. 321–25.

S.K. Kailasam, J.C. Lacombe, and M.E. Glicksman: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2605–10.

C. Wagner: Acta. Metall., 1969, vol. 17, pp. 99–107.

M.A. Dayananda: Def. Diffus. Forum, 2010, vols. 297–301, pp. 1451–60.

L.D. Hall: J. Chem. Phys., 1953, vol. 21, pp. 87–89.

T.N. Prasanthi, C. Sudha, S. Ravikirana, S. Saroja, N. Naveen Kumar, G.D. JanakiRam: Mater. Des., 2015, vol. 88, pp. 58–68.

T.N. Prasanthi, C. Sudha, S. Ravikirana, and S. Saroja: Mater. Des., 2016, vol. 93, pp. 180–93.

V.D. Scott, G. Love, and S.J.B. Reed: Quantitative Electron Probe Microanalysis, 2nd ed., Ellis Horwood Ltd., New York, 1995, pp .119–120.

Z. Guo, N. Saunders, J.P. Schillè, and A.P. Miodownik: Mater. Sci. Eng. A, 2009, vol. 499, pp. 7–13.

M. Ghosh, S. Chatterjee, and B. Mishra: Mater. Sci. Eng. A, 2003, vol. 363, pp. 268–74.

A. Laik, G.B. Kale, and K. Bhanumurthy: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2919–26.

S. Santra and A. Paul: Scripta Mater., 2015, vol. 103, pp. 18–21.

http://www.webelements.com/periodicity/molar_volume/. Accessed 20 Jan 2017.

H. Fujii, L. Cui, N. Tsuji, M. Maeda, K. Nakata, and K. Nogi: Mater. Sci. Eng. A, 2006, vol. 429, pp. 50–57.

S. Kundu and S. Chatterjee: Mater. Sci. Eng. A, 2008, vol. 480, pp. 316–22.

J.L. Murray: Phase Diagrams of Binary Ti Alloys, ASM International, Metals Park, OH, 1987, pp. 99–111.

H. Nakajima, S. Ohshida, K. Nonaka, Y. Yoshida, and F.E. Fujital: Scripta Mater., 1996, vol. 34, pp. 949–53.

Acknowledgments

The authors thank Dr. T. Jayakumar, former Director, MMG, and Dr. M. Vijayalakshmi, former Associate Director, PMG, for their encouragement and support throughout the period of this project. The authors also thank Dr. Shyamprasad and Mr. Vijay Khedekar, National Institute of Oceanography, Goa, for helping with the EPMA experiments, and UGC-DAE-CSR Kokkilamedu for the FESEM support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 26, 2016.

Rights and permissions

About this article

Cite this article

Prasanthi, T.N., Sudha, C. & Saroja, S. A Study of Interdiffusion in the Fe-C/Ti System Under Equilibrium and Nonequilibrium Conditions. Metall Mater Trans A 48, 1969–1980 (2017). https://doi.org/10.1007/s11661-017-3972-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-3972-6