Abstract

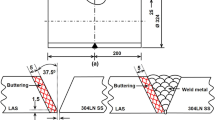

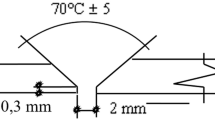

Low-alloy steel and 304LN austenitic stainless steel were welded using two types of buttering material, namely 309L stainless steel and IN 182. Weld metals were 308L stainless steel and IN 182, respectively, for two different joints. Cross-sectional microstructure of welded assemblies was investigated. Microhardness profile was determined perpendicular to fusion boundary. In situ tensile test was performed in scanning electron microscope keeping low-alloy steel-buttering material interface at the center of gage length. Adjacent to fusion boundary, low-alloy steel exhibited carbon-depleted region and coarsening of matrix grains. Between coarse grain and base material structure, low-alloy steel contained fine grain ferrite-pearlite aggregate. Adjacent to fusion boundary, buttering material consisted of Type-I and Type-II boundaries. Within buttering material close to fusion boundary, thin cluster of martensite was formed. Fusion boundary between buttering material-weld metal and weld metal-304LN stainless steel revealed unmixed zone. All joints failed within buttering material during in situ tensile testing. The fracture location was different for various joints with respect to fusion boundary, depending on variation in local microstructure. Highest bond strength with adequate ductility was obtained for the joint produced with 309L stainless steel-buttering material. High strength of this weld might be attributed to better extent of solid solution strengthening by alloying elements, diffused from low-alloy steel to buttering material.

Similar content being viewed by others

References

C. Jang, J. Lee, J. S. Kim and T. E. Jin; Mechanical property variation within Inconel 82/182 dissimilar metal weld between low alloy steel and 316 stainless steel, Int. J. of Pressure Vessels and Piping 2008, Vol. 85, pp. 635-646.

S. Missori and C. Koerber: Laser beam welding of austenitic-ferritic transition joints, Welding J., 1997, Vol.76, pp. 125s-134s.

J. N. DuPont, J. N. Lippold and S. D. Kiser: Welding Metallurgy and Weldability of Ni-Base Alloys, John Wiley & Sons Publication, 2009, Chapter 7, pp. 327-376.

A. Celik and A. Alsaran; Mechanical and structural properties of similar and dissimilar steel joints, Mats. Characterization 1999, Vol. 43, pp. 311-318.

H. Naffakh, M. Shamanian and F. Ashrafizadeh; Dissimilar welding of AISI 310 austenitic stainless stell to nickel-based alloy Inconel 657, J. of Mats. Processing Technol. 2009, Vol. 209, pp. 3628-3639.

M. Sireesha, S. K. Albert, V. Shankar and S. Sundaresan; A comparative evaluation of welding consumables for dissimilar welds between 316LN austenitic stainless steel and alloy 800, J. Of Nuclear Mats., 2000, vol. 279, pp. 65-76.

A. Wiltner, C. Linsmeier and T. Jacob: J. Chem. Phys., 2008, Vol. 129, pp. 084704-1–10.

C. Pan and E. Zhang: Morphologies of the transition region in dissimilar austenite-ferrite welds,Mater. Char., 1996, Vol. 36, pp. 5-10.

H. S. Hosseini, M. Shamanian and A. Kermanpur: Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds, Mater. Char., 2011, Vol. 62, pp. 425-431.

H. Naffakh, M. Shamanian and F. Ashrafizadeh: Dissimilar welding of AISI 310 austenitic stainless steel to nickel based alloy Inconel 657, J. Mats. Proc. Technol., 2009, Vol. 209, pp. 3628-3639.

H. T. Lee, S.L. Jeng, C. H. Yen and T.Y. Kuo: Dissimilar welding of nickel based alloy 690 to SUS 304L with Ti addition, J. of Nuclear Mats., 2004, Vol. 2004, pp. 59-69.

F. Matsuda and H. Nakagawa: Trans. of JWRI, 1984, Vol. 13, pp. 159-161.

T. W. Nelson, J. C. Lippold and M. J. Mills: Sci. Technol. Weld. Join., 1998, Vol. 3, pp. 249–254.

K. Sharma, H. K. Khandelwal, V. Bhasisn and R. Chhibber: Application of ball indentation technique for mechanical properties estimation of bi-metallic weld, Adv. Mats. Res., 2012, Vol. 585, pp. 342-346.

https://inis.iaea.org/search/search.aspx?orig_q=RN:43001715.

C. D. Lundin: Dissimilar metal welds – Literature review, Welding J. 1982, Vol. 61, pp. 585s-635s.

R. L. Klueh and J. F. King: Austenite-ferrite weld joint failures, Welding J. 1982, Vol. 61, pp. 302-311.

W. J. Mills and C. M. Brown: Metall. Mater. Trans. A 2001, Vol. 32A, pp. 1161-1174.

J. Gallego, A. R. Rodrigues, C. L. F. DeAssis and L. Montanari: Second phase precipitation in ultrafine-grained ferritic steel, Materials Research, 2014, Vol. 17, pp. 22-25, 10.1590/S1516-14392013005000199.

L. Yang, X. Dang, M. Li, and N. Ji: Proceedings of 2nd International Conference on Electronic and Mechanical Engineering and Information Technology (EMEIT 2012), Shenyang Liaoning, China, Prof. B. Wu, ed., Atlantis Press, Paris, pp. 697–700.

N. Wang, S. Mokadem, M. Rappaz and W. Kurz: Solidification cracking of superalloy single- and bi-crystals, Acta Mater., 2004, Vol. 52, pp. 3173-3182.

T. Y. Kuo and H. T. Lee: Effects of filler metal composition on joining properties of alloy 690 weldment, Mats. Sci. & Engg. A., 2002, vol. 338, pp. 202-212.

R. Dehmolaei, M. Shamanian and A. Kermanpur: Microstructural characterization of dissimilar welds between alloy 800 and HP heat-resistant steel, Mater. Character., 2008, Vol. 59, pp. 1447-1454.

W. F. Savage, E. F. Nipess and E.S. Szekeres: Study of weld interface phenomena in low alloy steel, Weld. J., 1976, Vol. 55, pp. 260-268.

C. Pan, R. Wang and J. Gui: 1990, J. Mater. Sci., Vol. 25, pp. 3281-3285.

T.W. Nelson, J.C. Lippold and M. J. Mills: 1999, Weld. J., Vol. 78, pp. 329s-337s.

M.D. Rowe, T.W. Nelson, and J. C. Lippold: 1999, Weld. J., Vol. 78, pp. 31s-37s.

J.N. DuPont and C.S. Kusko: Weld. J., 1996, Vol. 86, pp. 51s-54s.

R.E. Reed-Hill: Physical Metallurgy Principals (Chap. 18), 2nd edition, East West Press Pvt. Ltd., Delhi, 1973, pp. 701-748.

S.S. F. DeDafe, F.L. Sicupira, F.C.S. Matos, N.S. Cruz, D.R. Moreira, and D.B. Santos: Mater. Res. 2013, Vol. 16 (6), pp. 1229-36.

T.W. Nelson, J.C. Lippold, and M. J. Mills: Weld. J., 2000, Vol. 79, pp. 267-277.

M. W. A. Rashid, M. Gakim, Z. M. Rosli and M. A. Azam: Formation of Cr23C6 during the sensitization of AISI 304 stainless steel and its effect to pitting corrosion, Int. J. of Electrochemical Sci., 2012, Vol. 7, pp. 9465-9477.

http://www.steel-grades.com/Steel-Grades/Mould-Steel/aws-enicrfe-3.html.

G. D. Huang, D. K. Matlock and G. Krauss: Martensite formation, strain rate sensitivity, and deformation behavior of type 304 stainless steel sheet, Met. Mats. Trans A, 1989, Vol. 20, pp.1239-1246.

R. E. Schramm and R. P. Reed: Stacking fault energies of seven commercial austenitic stainless steels, Met. Mats, Trans A, 1975, Vol.6, pp. 1345-1351.

D.J. Siegel: Appl. Phys. Lett., 2005, Vol. 87, pp. 121901-1–1219013.

A.M. Shariatpanahi, Hassan Farhangi: Microstructure and mechanical properties of dissimilar ferritic and austenitic steel joints with an intermediate IN 182 buttering layer, Adv. Mats. Res., 2009, Vol. 83-86, pp. 449-456.

Acknowledgment

The authors are indebted to Director_CSIR-NML for providing infrastructural facilities to carry out the investigation and providing permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 9, 2014.

Rights and permissions

About this article

Cite this article

Ghosh, M., Santosh, R., Das, S.K. et al. Effect of Structural Heterogeneity on In Situ Deformation of Dissimilar Weld Between Ferritic and Austenitic Steel. Metall Mater Trans A 46, 3555–3568 (2015). https://doi.org/10.1007/s11661-015-2930-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2930-4