Abstract

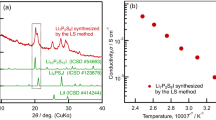

SiC composite ceramics for solar absorber and storage integration are new concentrating solar power materials. SiC composite ceramics for solar absorber and storage integration were fabricated using SiC, black corundum and kaolin as the raw materials, Co2O3 as the additive via pressureless graphite-buried sintering method in this study. Influences of Co2O3 on the microstructure and properties of SiC composite ceramics for solar absorber and storage integration were studied. The results indicate that sample D2 (5wt% Co2O3) sintered at 1 480 °C exhibits optimal performances for 119.91 MPa bending strength, 93% solar absorption, 981.5 kJ/kg (25–800 °C) thermal storage density. The weight gain ratio is 12.58 mg/cm2 after 100 h oxidation at 1 000 °C. The Co2O3 can decrease the liquid phase formation temperature and reduce the viscosity of liquid phase during sintering. The liquid with low viscosity not only promotes the elimination of pores to achieve densification, but also increases bending strength, solar absorption, thermal storage density and oxidation resistance. A dense SiO2 layer was formed on the surface of SiC after 100 h oxidation at 1 000 °C, which protects the sample from further oxidation. However, excessive Co2O3 will make the microstructure loose, which is disadvantageous to the performances of samples.

Similar content being viewed by others

References

Rashidi S, Liu Y, Khoosh-Ahang A, et al. Entropy Generation Analysis of Different Solar Thermal Systems[J]. Environ. Sci. Pollut. Res., 2020, 27(17): 20 699–20 724

Yang YL, Ye L. The Analysis of How to Improve of Thermal Efficiency for Solar Tower Plant[J]. Equipment Manuf. Technol., 2013, 3: 187–194

Xu ES, Hu ZL, Zhai RR, et al. Simulation and Exergy Analysis of Solar Thermal Tower Plants[J]. Proc. Chinese Soc. Electric. Eng., 2014, 34 (11): 1 799–1 806

Romero M, Buck R, Pacheco JE. An Update on Solar Central Receiver Systems, Projects, and Technologies[J]. J. Sol. Energy Eng., 2002, 124(2): 98–108

Benoit H, Spreafico L, Gauthier D, et al. Review of Heat Transfer Fluids in Tube-receivers Used in Concentrating Solar Thermal Systems: Properties and Heat Transfer Coefficients[J]. Renew. Sust. Energy Rev., 2016, 55: 298–315

Lao XB, Xu XH, Wu JF, et al. Effect of Silicon on Properties of Al2O3-SiCw Composite Ceramics in-situ Synthesized by Aluminium-assisted Carbothermal Reduction of Coal Series Kaolin for Solar Thermal Storage[J]. J. Alloy. Compd., 2017, 692: 825–832

Khare S, Dell’Amico M, Knight C, et al. Selection of Materials for High Temperature Sensible Energy Storage[J]. Sol. Energy Mater. Sol. Cells, 2013, 115: 114–122

Miro L, Oro E, Boer D, et al. Embodied Energy in Thermal Energy Storage (TES) Systems for High Temperature Applications[J]. Appl. Energy, 2015, 137: 793–799

Medrano M, Gil A, Martorell I, et al. State of the Art on High-temperature Thermal Energy Storage for Power Generation. Part 2-Case Studies[J]. Renew. Sust. Energy Rev., 2010, 14(1): 56–72

Wu JF, Liu M, Xu XH, et al. Research Progress of Absorber Materials in Tower Type Solar Thermal Power Plant[J]. Mater. Rep., 2013, 27(13): 57–61

Lu GH, Lu DD, Zhou HW, et al. Effect of Sintering Aid on Properties of Silicon Carbide Ceramics by Pressureless Liquid Phase Sintering[J]. J. Yili Normal Univ. (Nat. Sci. Edition), 2019, 13(02): 25–32

Li CR, Xie ZP, Kang GX, et al. Reserch and Application Progress of SiC Ceramics: A Review[J]. Bull. Chinese Ceram. Soc., 2020, 39(05): 1 353–1 370

Li CR, Xie ZP, Zhao L. Research and Application of Sintering Technologies for SiC Ceramic Materials: A Review[J]. J. Ceram., 2020, 41(02): 137–149

Fu ZD, Zhao J, Dai YJ, et al. Sintering Aids for Silicon Carbide Ceramics: Action Mechanisms and Research Progress[J]. J. Mater. Rep., 2021,35(01): 1 077–1 081

Xu XH, Rao ZG, Wu JF, et al. In-situ Synthesis and Thermal Shock Resistance of Cordierite/Silicon Carbide Composites Used for Solar Absorber Coating[J]. Sol. Energy Mater. Sol. Cells, 2014, 130: 257–263

Xu XH, Rao ZG, Wu JF, et al. In-Situ Synthesized Mullite Bonded Silicon Carbide Ceramics Used in Solar Heat Receiver[J]. J. Chinese Ceram. Soc., 2014, 42(07): 869–877

Sun XY, Chen H, Wang SQ, et al. Preparation and Thermal Conductivity of SiC-diamond Ceramics[J]. China’s Refractories, 2021, 55(02): 131–134

Belessiotis GV, Papadokostaki KG, Favvas EP, et al. Preparation and Investigation of Distinct and Shape Stable Paraffin/SiO2 Composite PCM Nanospheres[J]. Energy Convers. Manage., 2018, 168(1): 382–394

Ranjbar SG, Roudini G, Barahuie F. Fabrication and Characterization of Phase Change Material-SiO2 Nanocomposite for Thermal Energy Storage in Buildings[J]. J. Energy Storage, 2020, 27: 1–7

Chen YF, Wang MC, Hon MH. Phase Transformation and Growth of Mullite in Kaolin Ceramics[J]. J. Eur. Ceram. Soc., 2004, 24 (8): 2 389–2 397

Wu JF, Zhou Y, Liu Y, et al. Synthesis of Mullite from Shanxi Coal-series Kaolin by Molten Salt Method[J]. J. Wuhan. Univ. Technol. -Mater. Sci. Ed., 2016, 38(1): 24–29

Xu XH, Lao XB, Wu JF, et al. Microstructural Evolution, Phase Transformation, and Variations in Physical Properties of Coal Series Kaolin Powder Compact During Firing[J]. Appl. Clay Sci., 2015, 115: 76–86

Carty WM, Senapati U. Porcelain-Raw Materials, Processing, Phase Evolution, and Mechanical Behavior[J]. J. Am. Ceram. Soc., 1998, 81(1): 3–20

Jin H, Zhang W, Deng XY, et al. Effect of Different Aluminum Sources on the Preparation and Properties of SiC/Cordierite Composite Porous Ceramics[J]. Bull. Chinese Ceram. Soc. 2018, 37(02): 403–410

Bai CY, Deng XY, Li JB, et al. Fabrication and Properties of Cordierite-mullite Bonded Porous SiC Ceramics[J]. Ceram. Int., 2014, 40(4): 6 335–6 231

Xu XH, Xu XY, Wu JF, et al. Effect of Dolomite and Spodumene on the Performances of Andalusite Composite Ceramics for Solar Heat Transmission Pipeline[J]. Ceram. Int., 2015, 41(9): 11 861–11 869

Xu XH, Xu T, Wu JF, et al. Research on Andalusite Porous Ceramics Used for High Temperature Dust Removal[J]. J. Wuhan. Univ. Technol.-Mater. Sci. Ed., 2015, 37(1): 21–26

Xu XH, Rao ZG, Wu JF, et al. In-situ Synthesis and Thermal Shock Resistance of Cordierite/Silicon Carbide Composites Used for Solar Absorber Coating[J]. Sol. Energy Mater. Sol. Cells, 2014, 130: 257–263

Wu JF, Zhang YX, Xu XH, et al. A novel in-situ β-Sialon/Si3N4 Ceramic Used for Solar Heat Absorber[J]. Ceram. Int., 2015, 41(10): 14 440–14 446

Wu JF, Liu M, Xu XH, et al. Research Progress of Absorber Materials in Tower Type Solar Thermal Power Plant[J]. Mater. Rep., 2013, 27 (13): 57–61

Pappacena KE, Faber KT, Wang H, et al. Thermal Conductivity of Porous Silicon Carbide Derived from Wood Precursors[J]. J. Am. Ceram. Soc., 2007, 90(9): 2 855–2 862

Li JR, Lu WZ. Effects of AlN and Rare Earth Fluorides on the Thermal conductivity of SiC Ceramics with Impedance Spectroscopy Analysis[J]. J. Phys. Conf. Ser., 2021, 2011: 1–7

Xu XH, Tian JZ, Wu JF, et al. Fe2O3 on In-situ Synthesized SiCw/SiC Composite Ceramics for Solar Thermal Energy Storage[J]. J. Inorg. Mater., 2019, 34(10): 1 103–1 108

Zhang C, Yao XM, Li YS, et al. Effect of AlN Addition on the Thermal Conductivity of Pressureless Sintered SiC Ceramics[J]. Ceram. Int., 2015, 41(7): 9 107–9 114

Li YS, Yin J, Wu HB, et al. High Thermal Conductivity in Pressureless Densified SiC Ceramics with Ultra-low Contents of Additives Derived from Novel Boron-carbon Sources[J]. J. Eur. Ceram. Soc., 2014, 34(10): 2 591–2 595

Wu JF, Fang BZ, Xu XH, et al. Preparation of Cordierite-Mullite Heat Storage Ceramics for Solar Thermal Power Generation[J]. Acta Energiae Solaris Sinica, 2015, 36(06): 1 312–1 317

Liu JW, Zhu CH, Liang WZ, et al. Experimental Investigation on Micro-scale Phase Change Material Based on Sodium Acetate Trihydrate for Thermal Storage[J]. Sol. Energy, 2019, 193: 413–421

Wu JF, Fang BZ, Xu XH, et al. Preparation and Characterization of Alumina-Silicon Carbide-Zirconia Thermal Storage Ceramics for Solar Thermal Power Generation[J]. J. Chinese Ceram. Soc., 2013, 41(8): 1 063–1 069

Wu QD, Tong YF. Study on the Oxidation Mechanism and the Resistance to Oxidation of SiC Materials[J]. Ceram. Sci. Art, 2002, 01: 7–13

Rodriguez-Rojas F, Ortiz AL, Guiberteau F, et al. Oxidation Behaviour of Pressureless Liquid-phase-sintered α-SiC with Additions of 5Al2O3+3RE2O3 (RE=La, Nd, Y, Er, Tm, or Yb)[J]. J. Eur. Ceram. Soc., 2010, 30(15): 3 209–3 217

Zhang PF, Zhang YL, Chen GH, et al. High-temperature Oxidation Behavior of CVD-SiC Ceramic Coating in Wet Oxygen and Structural Evolution of Oxidation Product: Experiment and First-principle Calculations[J]. Appl. Surf. Sci., 2021, 556: 1–11

Xue XX, Xie P, Zhai YC, et al. Oxidation Resistance of TiN/O′-Sialon In-situ Composite Material[J]. Bull. Chinese Ceram. Soc., 2000, 02: 29–30

Tang HL, Zeng XR, Xiong XB, et al. Research of Oxidation Resistance of Short Carbon Fiber Reinforced SiC Composite by Hot-pressing[J]. J. Inorg. Mater., 2009, 24(2): 305–309

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

All authors declare that there are no competing interests.

Additional information

Funded by the National Key R&D Program of China (No. 2018YFB1501002)

Rights and permissions

About this article

Cite this article

Zhou, Y., Wu, J., Tian, K. et al. Effects of Co2O3 Addition on Microstructure and Properties of SiC Composite Ceramics for Solar Absorber and Storage. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 38, 1269–1277 (2023). https://doi.org/10.1007/s11595-023-2819-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-023-2819-9