Abstract

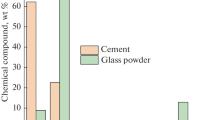

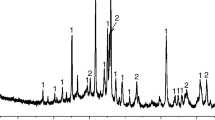

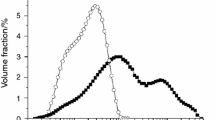

The early-age hydration characteristics of composite binder containing graphite powder (GP) with two different finenesses were investigated by determining the hydration heat, thermo gravimetric, morphology of hardened paste as well as the compressive strength of mortar. The experimental results show that: replacing 2%–6% of cement with graphite powder significantly improves the piezoresistive effect of early age mortar, can be used to monitor accidental loads caused by dropped objects, collisions, or other accident events, and thus avoids initial damage. Some GP provides additional nucleation sites that lead to a fast formation of hydration products (nucleation-site effect). However, due to the almost hydrophobic water contact angle, most of the GP causes a large number of micro-cracks in the hydrated paste (gap effect). Because of the lamellar shape and high surface energy, GP is easily balled and can not be uniformly distributed in the composite, resulting in clumping together and wrapping some of the cement particles (barrier effect). Due to nucleation-site effect, when the dosages of coarse and fine GP reached 2% and 4%, 1 d strength were increased by 9.1% and 9.6%, respectively. At 3 days, as the interior damage caused by the gap effect gradually increased, and the retarding effect on cement hydration caused by barrier effect was enhanced. GP has an obvious negative effect on compressive strength. However, micro-cracks caused by fine GP are less, so its negative effect on 3 d compressive strength is lower.

Similar content being viewed by others

References

Shi MX, Wang Q, Zhang ZK. Comparison of the Properties between High-volume Fly Ash Concrete and High-volume Steel Slag Concrete under Temperature Matching Curing Condition[J]. Construction & Building Materials, 2015(98): 649–655

McCarter WJ, Forde MC, Whittington HW. Resistivity Characteristics of Concrete[J]. Proceedings of the Institution of Civil Engineers, 1981, 71(1): 107–117

WHITING DA, NAGI MA. Electrical Resistivity of Concrete — A Literature Review[R]. Illinois: Portland Cement Association, 2003

Monfore GE. The Electrical Resistivity of Concrete[J]. Journal of the PCA Research & Development Laboratories, 1968, 10(2): 35–48

Han BG, Ou JP, Zhang LQ. Smart and Multifunctional Concrete toward Sustainable Infrastructures[M]. Singapore: Springer Nature Singapore PTE Ltd., 2017: 247

Wu JM, Liu JG, Yang F. Three-phase Composite Conductive Concrete for Pavement Deicing[J]. Construction & Building Materials, 2015(75): 129–135

Tuan CY. Roca Spur Bridge: The Implementation of an Innovative Deicing Technology[J]. Journal of Cold Regions Engineering, 2008, 22(1): 1–15

Dai YW, Sun MQ, Liu CG, et al. Electromagnetic Wave Absorbing Characteristics of Carbon Black Cement-based Composites[J]. Cement & Concrete Composites, 2010, 32(7): 508–513

Muthusamy S, Chung DDL. Carbon-fiber Cement-based Materials for Electromagnetic Shielding[J]. ACI Materials Journal, 2010, 107(6): 602–610

Wang JR, Ding YM. The Application of Conductive Concrete in the Grounding Network Reconstruction of Bai-Sha Hydropower Station[J]. Electrical Equipment, 2008, 9(4): 67–69

Zhang J, Xu L, Zhao Q. Investigation of Carbon Fillers Modified Electrically Conductive Concrete as Grounding Electrodes for Transmission Towers: Computational Model and Case Study[J]. Construction & Building Materials, 2017(145): 347–353

Shi ZQ, Chung DDL. Carbon Fiber-reinforced Concrete for Traffic Monitoring and Weighing in Motion[J]. Cement & Concrete Research, 1999, 29(3): 435–439

Zhang XY, Lü Y, Chen J, et al. Field Sensing Characteristic Research of Carbon Fiber Smart Material[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2015, 30(5): 914–917

Howser RN, Dhonde HB, Mo YL. Self-sensing of Carbon Nano-fiber Concrete Columns Subjected to Reversed Cyclic Loading[J]. Smart Materials & Structures, 2011, 20(8): 085031

Fu XL, Chung DDL. Radio-wave-reflecting Concrete for Lateral Guidance in Automatic Highways[J]. Cement & Concrete Research, 1998, 28(6): 795–801

Yehia S, Host J. Conductive Concrete for Cathodic Protection of Bridge Decks[J]. ACI Materials Journal, 2010, 107(6): 577–585

Xie P, Gu P, Beaudoin JJ. Electrical Percolation Phenomena in Cement Composites Containing Conductive Fibers[J]. Journal of Materials Science, 1996, 31(15): 4093–4097

Chen B, Wu K, Yao W. Conductivity of Carbon Fiber Reinforced Cement-based Composites[J]. Cement & Concrete Composites, 2004, 26(4): 291–297

Banthia N, Djeridance S, Pigeon M. Electrical Resistivity of Carbon and Steel Micro-fiber Reinforced Cements[J]. Cement & Concrete Research, 1992, 22(5): 804–814

Yehia S, Tuan CY, Ferdon D, et al. Conductive Concrete Overlay for Bridge Deck Deicing: Mixture Proportioning, Optimization, and Properties[J]. ACI Materials Journal, 2000, 97(2): 172–181

Chung DDL. Self-monitoring Structural Materials[J]. Materials Science & Engineering R: Reports, 1998, 22(2): 57–78

Chiarello M, Zinno R. Electrical Conductivity of Self-monitoring CFRC[J]. Cement & Concrete Composite, 2005, 27(4): 463–469

Shui ZH, Li C, Liao WD. Resistance Responses of Carbon Fiber Cement to Cycled Compressive Stresses[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2005, 20(4): 116–119

Han BG, Chen W, Ou JP. Piezo Resistivity of Cement-based Materials with Acetylene Carbon Black[J]. Acta Materiae Compositae Sinica, 2008, 25(3): 39–44

Wang XY, Sun MQ, Hou ZF, et al. Study on Electrical and Electro Thermal Properties of Nano Carbon Black Cement Mortar[J]. Journal of Functional Materials, 2006, 37(11): 1841–1843+1847

Yang YS, Dong FQ. On Electro Thermal Concrete of Doping Graphite Electricity-conductive Elementary Materials[J]. Journal of Functional Materials, 2008, 39(3): 385–387

Wen S, Chung DDL. Partial Replacement of Carbon Fiber by Carbon Black in Multifunctional Cement-matrix Composites[J]. Carbon, 2007, 45(3): 505–513

Gan WM, Huang X, Chen PF. Piezoresistivity of Cement Based Material with Small Amount of Graphite[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(5): 556–559+578

Rahhal V, Bonavetti V, Trusilewicz L, et al. Role of the Filler on Portland Cement Hydration at Early Ages[J]. Construction & Building Materials, 2012(27): 82–90

Wang YS, Lü LN, He YJ, et al. Effect of Calcium Silicate Hydrate Seeds on Hydration and Mechanical Properties of Cement[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2021, 36(1): 103–110

Wang Q, Yang J, Chen HH. Long-term Properties of Concrete Containing Limestone Powder[J]. Materials & Structures, 2017, 50(3): 168

Cui SP, Liu YX, Lan MZ, et al. Preparation and Properties of Graphite-cement Based Composites[J]. Journal of the Chinese Ceramic Society, 2007, 35(1): 91–95

Chen M, Gao P, Geng F, et al. Mechanical and Smart Properties of Carbon Fiber and Graphite Conductive Concrete for Internal Damage Monitoring of Structure[J]. Construction & Building Materials, 2017(142): 320–327

Cao HY, Yao W, Qin JJ. Seebeck Effect in Graphite-carbon Fiber Cement Based Composite[J]. Advanced Materials Research, 2011(177): 566–569

Sassani A, Ceylan H, Kim S, et al. Influence of Mix Design Variables on Engineering Properties of Carbon Fiber-modified Electrically Conductive Concrete[J]. Construction & Building Materials, 2017(152): 168–181

Chen B, Wu K, Yao W. Conductivity of Carbon Fiber Reinforced Cement-based Composites[J]. Cement & Concrete Composites, 2004(26): 291–297

Han BG, Ding SQ, Yu X. Intrinsic Self-sensing Concrete and Structures: A Review[J]. Measurement, 2015(59): 110–128

Zhang QQ, Wei Y. Quantitative Analysis on Reaction Degree of Slag-cement Composite System Based on Back-scattered-electron Image[J]. Journal of the Chinese Ceramic Society, 2015, 43(5): 563–569

Fowkes FM, Harkins WD. The State of Monolayers Adsorbed at the Interface Solid-Aqueous Solution[J]. Journal of the American Chemical Society, 1940, 62(12): 3 377–3 386

Tadros ME, Hu P, Adamson AW. Adsorption and Contact Angle Studies: I. Water on Smooth Carbon, Linear Polyethylene, and Stearic Acid-coated Copper[J]. Journal of Colloid & Interface Science, 1974, 49(2): 184–195

Shin YJ, Wang Y, Huang H, et al. Surface Energy Engineering of Grapheme[J]. Langmuir the ACS Journal of Surfaces and Colloids, 2010, 26(6): 3798–802

Kogan MJ, Dalcol I, Gorostiza P, et al. Supramolecular Properties of the Proline-rich γ-Zein N-Terminal domain[J]. Biophysical Journal, 2002, 83(2): 1 194–1 204

Raj R, Maroo SC, Wang EN. Wettability of Graphene[J]. Nano Letters, 2013, 13(4): 1 509–1 515

Zheng Y, Zaoui A. Wetting and Nanodroplet Contact Angle of the Clay 2:1 Surface: The Case of Na-montmorillonite (001)[J]. Applied Surface Science, 2016, 396: 717–722

Wang SR, Zhang Y, Abidi N, Cabrales L. Wettability and Surface Free Energy of Graphene Films[J]. Langmuir, 2009, 25(18): 11 078–11 081

Jia XW, Zhang X, Ma D, et al. Conductive Properties and Influencing Factors of Electrically Conductive Concrete: A Review[J]. Materials Review, 2017(21): 93–100

Dweck J, Buchler PM, Acv C, et al. Hydration of a Portland Cement Blended with Calcium Carbonate[J]. Thermochimica Acta, 2000, 346(1): 105–113

Savvatimskii AI, Aleksandr I. Melting Point of Graphite and Liquid Carbon[J]. Physics-Uspekhi, 2003, 46(12): 1 295–1 303

Wang K, Shah SP, Mishulovich A. Effects of Curing Temperature and NaOH Addition on Hydration and Strength Development of Clinker-free CKD-fly Ash Binders[J]. Cement & Concrete Research, 2004, 32(2): 299–309

Vassileva CG, Vassilev SV. Behaviour of Inorganic Matter During Heating of Bulgarian Coals: 1. Lignites[J]. Fuel Processing Technology, 2005, 86(12–13): 1 297–1 233

Song H, Jeong Y, Bae S, et al. A Study of Thermal Decomposition of Phases in Cementitious Systems Using HT-XRD and TG[J]. Construction & Building Materials, 2018(169): 648–661

Wang Q, Wang DQ, Chen HH. The Role of Fly Ash Microsphere in the Microstructure and Macroscopic Properties of High-strength Concrete[J]. Cement & Concrete Composite, 2017(83): 125–137

Soroka J. Portland Cement Paste and Concrete[M]. London: Macmillan Press Ltd, 1979: 35

Funding

Funded by the National Natural Science Foundation of China (Nos. 52208413 and 51908022) and the R&D Program of Beijing Municipal Education Commission (Nos. KM202210016011 and KM202110016013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, W., Song, S., Meng, X. et al. Early-age Hydration Characteristics of Composite Binder Containing Graphite Powder. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 1252–1261 (2022). https://doi.org/10.1007/s11595-022-2658-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2658-0