Abstract

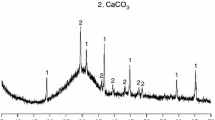

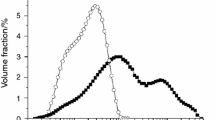

The hydration mechanisms of composite binders containing copper slag at different temperatures (20 °C and 50 °C) were investigated by hydration heat determination, TG/DTG, non-evaporable water content measurement and X-ray diffraction (XRD). The compressive strengths of mortars containing copper slag cured at different temperatures were also determined. In addition to plain cement, quartz powder with a similar particle size and the same replacement ratio as copper slag was selected as the control sample. The results show that the addition of quartz powder has a slight acceleration effect on the hydration of cement, while the addition of copper slag has a strong retarding effect on the hydration of cement. The second exothermic peak of the composite binder containing copper slag is delayed as the copper slag content increases, but this trend weakens at high temperatures. The hydration heat of the composite binder containing copper slag decreases with increasing copper slag addition. Moreover, the hydration heat of the composite binder containing copper slag is higher than that of the composite binder containing an equal mass of quartz powder within 72 h. Copper slag has pozzolanic activity and consumes Ca(OH)2 in hardened paste, although the pozzolanic activity of copper slag is low. However, the pozzolanic activity of copper slag is enhanced at high temperature. Furthermore, the reaction of copper slag does not produce new crystalline products compared to those produced by cement. Moreover, compared to hardened plain cement, the hardened composite binder containing copper slag has a higher non-evaporable water content gain rate. The mortar containing copper slag also has a higher compressive strength gain rate than the mortar containing equal mass quartz powder. Although the compressive strength of mortar containing copper slag is lower than that of plain cement mortar, it is higher than that of mortar containing quartz powder.

Similar content being viewed by others

References

Han F, Wang Q, Liu M, Mei Y. Early hydration properties of composite binder containing limestone powder with different finenesses. J Therm Anal Calorim. 2016;123:1141–51.

Wang Q, Wang D, Zhuang S. The soundness of steel slag with different free CaO and MgO contents. Constr Build Mater. 2017;151:138–46.

Liu S, Kong Y, Wang L. A comparison of hydration properties of cement–low quality fly ash binder and cement–limestone powder binder. J Therm Anal Calorim. 2014;116:937–43.

Feng J, Liu S, Wang Z. Effects of ultrafine fly ash on the properties of high-strength concrete. J Therm Anal Calorim. 2015;121:1213–23.

Wang Q, Yang J, Chen H. Long-term properties of concrete containing limestone powder. Mater Struct. 2017;50:168.

Zhang T, Yu Q, Wei J, Li J. Investigation on mechanical properties, durability and micro-structural development of steel slag blended cements. J Therm Anal Calorim. 2012;110:633–9.

Zhang T, Yu Q, Wei J, et al. Study on optimization of hydration process of blended cement[J]. J Therm Anal Calorim. 2012;107:489–98.

Liu S, Li Q, Han W. Effect of various alkalis on hydration properties of alkali-activated slag cements. J Therm Anal Calorim. 2018;131:3093–104.

Hu J. Comparison between the effects of superfine steel slag and superfine phosphorus slag on the long-term performances and durability of concrete. J Therm Anal Calorim. 2017;128:1251–63.

Zhang T, Yu Q, Wei J, Zhang P, Chen P. Improvement of surface cementitious properties of coarse fly ash by dehydration and rehydration processes. J Therm Anal Calorim. 2012;109:265–71.

Wang Q, Wang D, Chen H. The role of fly ash microsphere in the microstructure and macroscopic properties of high-strength concrete. Cem Concr Compos. 2017;83:125–37.

Joshaghani A, Moeini MA, Balapour M, Moazenian A. Effects of supplementary cementitious materials on mechanical and durability properties of high-performance non-shrinking grout (HPNSG). J Sustain Cem-Based Mater. 2018;7:38–56.

Wang Q, Yan P, Mi G. Effect of blended steel slag-GBFS mineral admixture on hydration and strength of cement. Constr Build Mater. 2012;35:8–14.

Han F, Zhang Z, Liu J, Yan P. Effect of water-to-binder ratio on the hydration kinetics of composite binder containing slag or fly ash. J Therm Anal Calorim. 2017;128:855–65.

Han F, Zhang Z, Liu J, Yan P. Hydration kinetics of composite binder containing fly ash at different temperatures. J Therm Anal Calorim. 2016;124:1691–703.

Liu S, Xie G, Wang S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J Therm Anal Calorim. 2015;119:47–55.

Han F, Zhang Z. Hydration, mechanical properties and durability of high-strength concrete under different curing conditions. J Therm Anal Calorim. 2018;132:823–34.

Zhang Z, Wang Q, Chen H. Properties of high-volume limestone powder concrete under standard curing and steam-curing conditions. Powder Technol. 2016;301:16–25.

Gorai B, Jana RK. Characteristics and utilisation of copper slag-a review. Resour Conserv Recycl. 2003;39:299–313.

Geetha S, Madhavan S. High performance concrete with copper slag for marine environment. Mater Today: Proc. 2017;4:3525–33.

Sharma R, Khan RA. Influence of copper slag and metakaolin on the durability of self compacting concrete. J Clean Prod. 2017;171:1171–86.

Wu W, Zhang W, Ma G. Optimum content of copper slag as a fine aggregate in high strength concrete. Mater Design. 2010;31:2878–83.

Takebe H, Tomita S, Saitoh A, et al. Effect of crystallization on microstructure and elution properties in copper slag. J Sustain Metall. 2017;3:543–50.

Wang Z, Zhang T, Zhou L. Investigation on electromagnetic and microwave absorption properties of copper slag-filled cement mortar. Cem Concr Compos. 2016;74:174–81.

Chun T, Ning C, Long H, Li J, Yang J. Mineralogical characterization of copper slag from tongling nonferrous metals group China. JOM. 2016;68:2332–40.

Zuo Z, Yu Q, Wei M, Xie H, Duan W, Wang K, Qin Q. Thermogravimetric study of the reduction of copper slag by biomass. J Therm Anal Calorim. 2016;126:481–91.

Zuo Z, Yu Q, Xie H, Yang F, Qin Q. Thermodynamic analysis of reduction in copper slag by biomass molding compound based on phase equilibrium calculating model. J Therm Anal Calorim. 2018;132:1277–89.

Sarfo P, Das A, Wyss G, Young C. Recovery of metal values from copper slag and reuse of residual secondary slag. Waste Manage. 2017;70:272–81.

Raposeiras AC, Vargas-Cerón A, Movilla-Quesada D, Castro-Fresno D. Effect of copper slag addition on mechanical behavior of asphalt mixes containing reclaimed asphalt pavement. Constr Build Mater. 2016;119:268–76.

Behnood A, Gharehveran MM, Asl FG, Ameri M. Effects of copper slag and recycled concrete aggregate on the properties of CIR mixes with bitumen emulsion, rice husk ash, Portland cement and fly ash. Constr Build Mater. 2015;96:172–80.

Mavroulidou M. Mechanical properties and durability of concrete with water cooled copper slag aggregate. Waste Biomass Valor. 2017;8:1841–54.

Madheswaran CK, Ambily PS, Dattatreya JK, Rajamane NP. Studies on use of copper slag as replacement material for river sand in building constructions. J Inst Eng India Ser A. 2014;95:169–77.

Sharma R, Khan RA. Durability assessment of self compacting concrete incorporating copper slag as fine aggregates. Constr Build Mater. 2017;155:617–29.

Shi C, Meyer C, Behnood A. Utilization of copper slag in cement and concrete. Resour Conserv Recycl. 2008;52(10):1115–20.

Murari K, Siddique R, Jain KK. Use of waste copper slag, a sustainable material. J Mater Cycles Waste Manag. 2015;17:13–26.

Mag DA, Atc S, Andrade N. Blasted copper slag as fine aggregate in Portland cement concrete. J Environ Manag. 2017;196:607–13.

Najimi M, Sobhani J, Pourkhorshidi AR, DuEdwin RS, Gruyaert E, Belie ND. Influence of intensive vacuum mixing and heat treatment on compressive strength and microstructure of reactive powder concrete incorporating secondary copper slag as supplementary cementitious material. Constr Build Mater. 2017;155:400–12.

Mirhosseini SR, Fadaee M, Tabatabaei R, Fadaee MJ. Mechanical properties of concrete with Sarcheshmeh mineral complex copper slag as a part of cementitious materials. Constr Build Mater. 2017;134:44–9.

Najimi M, Sobhani J, Pourkhorshidi AR. Durability of copper slag contained concrete exposed to sulfate attack. Constr Build Mater. 2011;25:1895–905.

Moura WA, Gonçalves JP, Lima MBL. Copper slag waste as a supplementary cementing material to concrete. J Mater Sci. 2007;42:2226–30.

Chen Z, Yang EH. Early age hydration of blended cement with different size fractions of municipal solid waste incineration bottom ash. Constr Build Mater. 2017;156:880–90.

Weeks C, Hand RJ, Sharp JH. Retardation of cement hydration caused by heavy metals present in ISF slag used as aggregate. Cem Concr Res. 2008;30:970–8.

Zhang Z, Zhang B, Yan P. Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr Build Mater. 2011;105:82–93.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Guo, R., Shi, P. et al. Hydration mechanisms of composite binders containing copper slag at different temperatures. J Therm Anal Calorim 137, 1919–1928 (2019). https://doi.org/10.1007/s10973-019-08116-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08116-9