Abstract

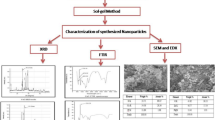

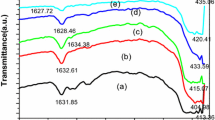

Using the idea of material design and the design of reaction system and conditions, quasi-one-dimensional nano-materials with ribbon-like structure were successfully prepared. Nickel tartrate nanobelts were prepared by a sol-precipitation route, using nickel chloride hexahydrate and tartaric acid as raw materials, and using ammonium hydroxide as pH value modifier. Nickel nanobelts with smooth surface were prepared by a thermal-decomposition route at about 355 °C for about 30 minutes, in CO2 atmosphere, using nickel tartrate nanobelts as precursor. The analyses of atomic absorption spectrometry (AAS), organic elemental analyzer (OEA), infrared spectroscopy (IR) and ultraviolet-visible spectroscopy (UV-Vis) indicate that the products as-prepared is nickel tartrate, which has octahedral configuration of co-ordination of nickel atoms. The images of scanning electron microscopy (SEM) indicate that the morphology of nickel tartrate as-prepared is an obvious belt structure with clear and smooth surface. The images of SEM also indicate that the nickel nanobelts have clear and smooth surface. The nickel nanobelts are about tens of micrometers in length, tens of nanometers in thickness, and 100–200 nanometers in width.

Similar content being viewed by others

References

Vojtěch D, Michalcová A, Klementová M, et al. Nanocrystalline Nickel as a Material with High Hydrogen Storage Capacity[J]. Mater. Lett., 2009, 63: 1074–1076

Zhang YF, Park M, Kim HY, et al. Moderated Surface Defects of Ni Particles Encapsulated with NiO Nanofibers as Supercapacitor with High Capacitance and Energy Density[J]. J. Colloid. Interface. Sci., 2017, 500: 155–163

You B, Liu X, Liu X, et al. Efficient H2 Evolution Coupled with Oxidative Refining of Alcohols via a Hierarchically Porous Nickel Bifunctional Electrocatalyst[J]. ACS Catal., 2017, 7: 4564–4570

Wang WH, Bai J, Wang JZ, et al. Self-assembly 3D Needle-like Nickel Nanostructure Growth on Carbon Fibers by Regulating Prepare Conditions and Exploited as Bifunctional Material[J]. Appl. Surf. Sci., 2019, 465: 82–92

Lin Z, Fan S, Liu M, et al. Excellent Anti-arc Erosion Performance and Corresponding Mechanisms of a Nickel-belt-reinforced Silver-based Electrical Contact Material[J]. J. Alloys. Compd., 2019, 788: 163–171

Wei W, Chen W, Ding L, et al. Construction of Hierarchical Three-dimensional Interspersed Flower-like Nickel Hydroxide for Asymmetric Supercapacitors[J]. Nano Res., 2017, 10: 3726–3742

Li D, Guo K, Wang F, et al. Enhanced Microwave Absorption Properties in C Band of Ni/C Porous Nanofibers Prepared by Electrospinning[J]. J. Alloys. Compd., 2019, 800: 294–304

Amaral Junior MA, Marcuzzo JS, Pinheiro BS, et al. Study of Reflection Process for Nickel Coated Activated Carbon Fiber Felt Applied with Electromagnetic Interference Shielding[J]. J. mater. Res. technol., 2019, 8(5): 4040–4047

Kumar A, Ashok A, Bhosale RR, et al. In situ DRIFTS Studies on Cu, Ni and CuNi Catalysts for Ethanol Decomposition Reaction[J]. Catal. Lett., 2016, 146: 778–787

Chi Y, Li T, Chong JY, et al. Graphene-protected Nickel Hollow Fibre Membrane and Its Application in the Production of High-Performance Catalysts[J]. J. Memb. Sci., 2020, 597: 117 617(1–6)

Vinicius DS, Thiago AS, Francisco JAL, et al. Solution Blow Spun Nickel Oxide/Carbon Nanocomposite Hollow Fibres as an Effificient Oxygen Evolution Reaction Electrocatalyst[J]. Int. J. Hydrogen. Energy, 2019, 44: 14877–14888

Bell TE, Torrente-Murciano L. H2 Production via Ammonia Decomposition Using Non-noble Metal Catalysts: A Review[J]. Top. Catal., 2016, 59: 1438–1457

Wang M, Tan X, Motuzas J, et al. Hydrogen Production by Methane Steam Reforming Using Metallic Nickel Hollow Fiber Membranes[J]. J. Memb. Sci., 2021, 620: 118 909(1–9)

Wang M, Zhou Y, Tan X, et al. Nickel Hollow Fiber Membranes for Hydrogen Separation from Reformate Gases and Water Gas Shift Reactions Operated at High Temperatures[J]. J. Memb. Sci., 2019, 575: 89–97

Jiang F, Fang Y, Xue Q, et al. Graphene-based Carbon Nano-fibers Grown on Thin-sheet Sinter-locked Ni-fiber as Self-Supported Electrodes for Supercapacitors[J]. Mater. Lett., 2010, 64: 199–202

He B, Ling Y, Xu J, et al. Effect of Nickel Impregnated Hollow Fiber Anode for Micro Tubular Solid Oxide Fuel Cells[J]. J. Power. Sources, 2014, 258: 391–394

Yao M, Hu Z, Xu Z, et al. Template Synthesis and Characterization of Nanostructured Hierarchical Mesoporous Ribbon-like NiO as High Performance Electrode Material for Supercapacitor[J]. Electrochim. Acta, 2015, 158: 96–104

Xi C, Zhu G, Liu Y, et al. Belt-Like Nickel Hydroxide Carbonate/Reduced Graphene Oxide Hybrids: Synthesis and Performance as Supercapacitor Electrodes[J]. Colloids Surf. A, 2018, 538: 748–756

Mrinmoy M, Madhurima D, Sirshendu D. A Novel Ultrafifiltration Grade Nickel Iron Oxide Doped Hollow Fiber Mixed Matrix Membrane: Spinning, Characterization and Application in Heavy Metal Removal [J]. Sep. Purif. Technol., 2017, 188: 155–166

Wang D, Zhou WL, McCaughy BF, et al. Electrodeposition of Metallic Nanowire Thin Films Using Mesoporous Silica Templates[J]. Adv. Mater., 2003, 15: 130–133

Lu X, Zhao C. Electrodeposition of Hierarchically Structured Three-dimensional Nickel-iron Electrodes for Efficient Oxygen Evolution at High Current Densities[J]. Nat. Commun., 2015, 6: 6616(1–7)

Liu Z, Li S, Yang Y, et al. Complex-surfactant-assisted Hydrothermal Route to Ferromagnetic Nickel Nanobelts[J]. Adv. Mater., 2003, 15: 1946–1948

Srinivas V, Barik SK, Bhaskarjyoti B, et al. Magnetic and Electrical Properties of Oxygen Stabilized Nickel Nanofibers Prepared by the Borohydride Reduction Method[J]. J. Magn. Magn. Mater., 2008, 320: 788–795

Wu H, Zhang R, Liu X, et al. Electrospinning of Fe, Co, and Ni Nanofibers: Synthesis, Assembly, and Magnetic Properties[J]. Chem. Mater., 2007, 19: 3506–3511

Li T, Liu Y, Peng T, et al. Controlled Synthesis of Polycrystalline Nickel Oxalate Nanofibers by the Mild Thermal Precipitation and Aging Process[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2011, 26(6): 1041–1043

Li T, Liu Y, Ma G, et al. Spherical and Radiate Ni Particles Prepared by the Tartrate Precipitation and Thermal Decomposition Method[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2013, 28(5): 857–861

Dorneanu PP, Airinei A, Homocianu M, et al. Photophysical and Surface Characteristics of Electrospun Polysulfone/Nickel Fibers[J]. Mater. Res. Bull., 2015, 64: 306–311

Khalili S, Chenari HM, Mottaghian F. Electrospinning Fabrication of Nickel Oxide Fibers: Whole Powder Pattern Modeling (WPPM) Approach, Morphology, Optical and Magnetic Properties[J]. Mater. Res. Bull., 2021, 140: 111 305(1–9)

Li T, Ma G, Chen J, et al. Controlled Synthesis of Core-shell Nickel Microspheres with Solid Core and Porous Shell by Precipitation and Thermal Decomposition Method[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2019, 34(4): 824–829

Li T, Liu Y, Ma G. Preparation of Submicro-porous Nickel Wafers by Molding-decomposition-sintering Method Using Nickel Oxalate Nano-rods as Precursors[J]. Rare Metal Mat. Eng., 2016, 45(6): 1396–1400

Li T, Liu Y, Ma G. Guidance Evolution Mechanism of Nickel Oxalate Microstructure for Formation of Polycrystalline Nickel Nano-fibers[J]. Rare Metal Mat. Eng., 2017, 46(9): 2371–2374

Kukula P, Cerveny L. Characterization of Chirally Modified Raney Nickel and Compounds of Tartaric Acid and Nickel[J]. Appl. Catal. A, 2002, 223: 43–55

Li T, Lu Z, Chen W. A Preparation Method of Nickel Tartrate Nanobelts[P]. CN, 201710447437.3

Jones TE, Baddeley CJ. An Investigation of the Adsorption of (R,R)-tartaric Acid on Oxidized Ni{111} Surface[J]. J. Mol. Catal. A Chem., 2004, 216: 223–231

Funding

Funded by the Doctoral Fund of Chengdu University (2081919131) and the Open Fund of Material Corrosion and Protection Key Laboratory of Sichuan Province (2021CL27)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, T., Chen, J. & Ma, G. Self-assemble Mechanism of Nickel Nanobelts Prepared by Sol-precipitation and Thermal Decomposition Route. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 206–211 (2022). https://doi.org/10.1007/s11595-022-2519-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2519-x