Abstract

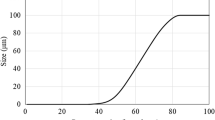

Phlogopite-based geopolymer was first prepared successfully under the activation of lye by compression molding at 50 MPa for 1 minute. The geopolymer was endowed with nonpolar surface via brushing modified liquid at room temperature. Swill-cooked dirty oil, whose main component was fatty acid, was used as nonpolar modifier. The raw materials and geopolymer samples were characterized by XRD, FT-IR and SEM. The compression strength of 7-day specimen run up to 36.8 MPa and its surface static water contact angle could reach 132°. The solubility of phlogopite powder directly affected the compressive strength of geopolymers and the evaluation index of mechanical strength of geopolymer based on the solubility of phlogopite powder was proposed.

Similar content being viewed by others

References

Davidovits J. Synthesis of New High-temperature Geo-polymers for Reinforced Plastics/Composites[C]. Proceedings of PACTEC 79, Society of Plastic Engineers, 1979: 151–174

Kong D L Y, Sanjayan J G, Sagoe-Crentsil K. Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash after Exposure to Elevated Temperatures[J]. Cement & Concrete Research, 2007, 37(12): 1583–1589

Zhang L, Ahmari S, Zhang J. Synthesis and Characterization of Fly Ash Modified Mine Tailings-based Geopolymers[J]. Construction & Building Materials, 2011, 25(9): 3773–3781

Lin W, Zhou F, Luo W, et al. Recycling the Waste Dolomite Powder with Excellent Consolidation Properties: Sample Synthesis, Mechanical Evaluation, and Consolidation Mechanism Analysis[J]. Construction and Building Materials, 2021, 290: 123198

Li H, Xu DL. The Future Resources for Eco-building Materials: II. Fly Ash and Coal Waste[J]. Journal of Wuhan University of Technology: Materials Science Edition, 2009(04): 157–160

Jaarsveld J G S V, Deventer J S J V, Lukey G C. The Effect of Composition and Temperature on the Properties of Fly Ash- and Kaolinite-based Geopolymers[J]. Chemical Engineering Journal, 2002, 89(1): 63–73

Bakri A M M A, Kamarudin H, Bnhussain M, et al. Effect of Na2SiO3/NaOH Ratios and NaOH Molarities on Compressive Strength of Fly Ash-based Geopolymer[J]. Aci Materials Journal, 2012, 109(5): 503–508

Gunasekara C, Law D W, Setunge S, et al. Effect of Element Distribution on Strength in Fly Ash Geopolymers[J]. ACI Materials Journal, 2017, 114(5): 795–808

Duxson P, Mallicoat S W, Lukey G C. The Effect of Alkali and Si/Al Ratio on the Development of Mechanical Properties of Metakaolin-based Geopolymers[J]. Colloids & Surfaces A Physicochemical & Engineering Aspects, 2015, 292(1): 8–20

Yao X, Tao Y, Zhang Z. Fly Ash-based Geopolymers: Effect of Slag Addition on Efflorescence[J]. Journal of Wuhan University of Technology(Materials Science Edition), 2016, 31(3): 689–694

Xiaolu G, Huisheng X, Mingfeng X. Static and Dynamic Leaching Experiments of Heavy Metals from Fly Ash-based Geopolymers[J]. Journal Wuhan University of Technology -Materials Science Edition, 2013, 28(5): 938–943

Lin W, Zhou F, Luo W, et al. Alkali-activated Dolomite and Its Outstanding Mechanical Strength[J]. Materials Letters, 2020, 270: 127682

Duan P, Yan C, Luo W, et al. A Novel Surface Waterproof Geopolymer Derived from Metakaolin by Hydrophobic Modification[J]. Materials Letters, 2016, 164: 172–175

Hos J P, Mccormick P G, Byrne L T. Investigation of a Synthetic Aluminosilicate Inorganic Polymer[J]. Journal of Materials Science, 2002, 37(11): 2311–2316

Mathew G, Joseph B. Flexural Behaviour of Geopolymer Concrete Beams Exposed to Elevated Temperatures[J]. Journal of Building Engineering, 2017, 15: 311–317

Panda B, Paul S C, Hui L J, et al. Additive Manufacturing of Geopolymer for Sustainable Built Environment[J]. Journal of Cleaner Production, 2017, 167: 281–288

Singhal A, Gangwar B P, Gayathry J M. CTAB Modified Large Surface Area Nanoporous Geopolymer with High Adsorption Capacity for Copper Ion Removal[J]. Applied Clay Science, 2017, 150: 106–114

Davidovits J. Geopolymers and Geopolymeric Materials[J]. Journal of Thermal Analysis, 1989, 35(2): 429–441

Davidovits J. Geopolymers: Inorganic Polymeric New Materials[J]. Journal of Thermal Analysis & Calorimetry, 1991, 37(8): 1633–1656

Haha M B, Saout G L, Winnefeld F, et al. Influence of Activator Type on Hydration Kinetics, Hydrate Assemblage and Microstructural Development of Alkali Activated Blast-furnace Slags[J]. Cement & Concrete Research, 2011, 41(3): 301–310

Jin F, Gu K, Al-Tabbaa A. Strength and Drying Shrinkage of Reactive MgO Modified Alkali-activated Slag Paste[J]. Construction & Building Materials, 2014, 51(4): 395–404

Sreenivasan H, Kinnunen P, Heikkinen E P, et al. Thermally Treated Phlogopite as Magnesium-rich Precursor for Alkali Activation Purpose[J]. Minerals Engineering, 2017, 113: 47–54

Wang J W, Li X Z, Fan M, et al. Porous β-sialon Planar Membrane with a Robust Polymer-derived Hydrophobic Ceramic Surface[J]. Journal of Membrane Science, 2017, 535: 63–69

Gu J, Wang J, Li Y, et al. Engineering Durable Hydrophobic Surfaces on Porous Alumina Ceramics Using In-situ Formed Inorganic-organic Hybrid Nanoparticles[J]. Journal of the European Ceramic Society, 2017, 37(15): 4843–4848

Cao W, Sun X, Chen F, et al. Prospect on Discerning Technology of Swill-cooked Dirty Oil[J]. China Oils & Fats, 2012, 37(5): 1–5

Zhan H, Xi J, Zhao K, et al. A Spectral-mathematical Strategy for the Identification of Edible and Swill-cooked Dirty Oils Using Terahertz Spectroscopy[J]. Food Control, 2016, 67: 114–118

Gao S, Luo T, Zhou Q, et al. A Novel and Efficient Method on the Recovery of Nanosized CeO2 in Ce(3+) Wastewater Remediation Using Modified Sawdust as Adsorbent[J]. Journal of Colloid & Interface Science, 2017, 512: 629–637

Zhou Q, Luo T, Yang H, et al. From Fly Ash Waste Slurry to Functional Adsorbent for Valuable Rare Earth Ion Separation: an Ingenious Combination Process Involving Modification, Dewatering and Grafting[J]. Journal of Colloid & Interface Science, 2017, 513(2018): 427–437

Bloss F D, Gibbs G V, Cummings D. Polymorphism and Twinning in Synthetic Fluorophlogopite[J]. Journal of Geology, 1963, 71(5): 537–548

Jacobs H, Metzner U, Kirchgaessner R, et al. Calculated from ICSD using POWD-12[J]. Anorg. Allg. Chem., 1991, 598(1): 175–192

Khan M Z N, Shaikh F U A, Hao Y, et al. Synthesis of High Strength Ambient Cured Geopolymer Composite by Using Low Calcium Fly Ash[J]. Construction & Building Materials, 2016, 125: 809–820

Sturm P, Gluth G J G, Brouwers H J H, et al. Synthesizing One-part Geopolymers from Rice Husk Ash[J]. Construction & Building Materials, 2016, 124: 961–966

Andini S, Cioffi R, Colangelo F, et al. Coal Fly Ash as Raw Material for the Manufacture of Geopolymer-based Products[J]. Waste Management, 2008, 28(2): 416–423

Gao K, Lin K L, Wang D Y, et al. Effects SiO2 /Na2O Molar Ratio on Mechanical Properties and the Microstructure of Nano-SiO2 Metakaolin-based Geopolymers[J]. Construction & Building Materials, 2014, 53(4): 503–510

Karim M R, Zain M F M, Jamil M, et al. Fabrication of a Non-cement Binder Using Slag, Palm Oil Fuel Ash and Rice Husk Ash with Sodium Hydroxide[J]. Construction & Building Materials, 2013, 49(6): 894–902

Zawrah M F, Gado R A, Feltin N, et al. Recycling and Utilization Assessment of Waste Fired Clay Bricks (Grog) with Granulated Blast-furnace Slag for Geopolymer Production[J]. Process Safety & Environmental Protection, 2016, 103: 237–251

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by the National Natural Science Foundation of China (Nos. 2018033022, 2017036019),the Open Funds of Engineering Research Center of Nano-Geo Materials of Ministry of Education, China University of Geosciences (No.NGM2017KF001), the Fundamental Research Funds for the Central Universities (No.185206011), and the Open Funds of the State Key Laboratory of Refractories and Metallurgy (Wuhan University of Science and Technology)(No.G201806)

Rights and permissions

About this article

Cite this article

Lin, W., Luo, W., Zhang, G. et al. Preparation of Phlogopite-based Geopolymer and Its Surface Nonpolar Modification. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 433–438 (2021). https://doi.org/10.1007/s11595-021-2427-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2427-5