Abstract

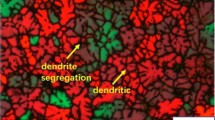

During the process of liquid forging, a host of hot cracking defects were found in the Al-Cu-Mg-Zn aluminum alloy. Therefore, mechanical tests and analyses by optical microscope, scanning electron microscope, and X-ray diffraction were performed to research the influences of zinc, magnesium, and copper (three main alloying elements) on hot cracking tendency and mechanical properties. It was concluded that all the three alloying elements exerted different effects on the performances of newly designed alloys. And the impact of microstructures on properties of alloys was stronger than that of solution strengthening. Among new alloys, Al-5Cu-4.5Mg-2.5Zn alloy shows better properties as follows: σb=327 MPa, δ=2.7%, HB=107 N/mm2, and HCS=40.

Similar content being viewed by others

References

Kasilingam S, Iqbal M A, Chandel P S, et al. Study of the Constitutive Behavior of 7075-T651 Aluminum Alloy[J]. International Journal of Impact Engineering, 2017, 108: 171–190

Coloma P.S, Izagirre U, Belaustegi Y, et al. Chromium-Free Conversion Coatings Based on Inorganic Salts (Zr/Ti/Mn/Mo) for Aluminum Alloys Used in Aircraft Applications[J]. Applied Surface Science, 2015, 345: 24–35

Park D.H, Choi S W, Kim J H, et al. Cryogenic Mechanical Behavior Fig.14 Microstructures of alloys with different copper contents: (a) 8th alloy; (b) 9th alloy; (c) 10th alloy; (d) 1st alloy; (e) 11th alloy (8th is Al-2Cu-3.5Mg-2.5Zn alloy; 9th is Al-2Cu-3.5Mg-2.5Zn alloy; 1st is Al-5Cu-3.5Mg-2.5Zn alloy; 11th is Al-5Cu-3.5Mg-2.5Zn alloy) 182 Vol.35 No.1 SUN Yonggen et al: Effect of Zn/Mg/Cu Additions on Hot Cracking Tendency… of 5000- and 6000-Series Aluminum Alloys: Issues on Application to Offshore Plants[J]. Cryogenics, 2015, 68: 44–58

Xu Y.Q, Tong C Y, Zhan L H, et al. A Low-Density Pulse-Current-Assisted Age Forming Process for High-Strength Aluminum Alloy Components[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(9-12): 3371–3384

Cao J, Li F, Ma X, et al. Study of Fracture Behavior for Anisotropic 7050-T7451 High-Strength Aluminum Alloy Plate[J]. International Journal of Mechanical Sciences, 2017, 128-129: 445–458

Alireza V, Santu R, Sunil G, et al. New Bayesian-Optimization-Based Design of High-Strength 7xxx-Series Alloys from Recycled Aluminum[J] JOM, 2018, 70(11): 2704–2709

Benedetti M, Fontanari V, Bandini M, et al. High- and Very High-Cycle Plain Fatigue Resistance of Shot Peened High-Strength Aluminum Alloys: The Role of Surface Morphology[J]. International Journal of Fatigue, 2015, 70: 451–462

Hawryluk M. Review of Selected Methods of Increasing the Life of Forging Tools in Hot Die Forging Processes[J]. Archives of Civil and Mechanical Engineering, 2016, 16(4): 845–866

Xu W, Li W, Wang Y. Experimental and Theoretical Analysis of Wear Mechanism in Hot-Forging Die and Optimal Design of Die Geometry[J]. Wear, 2014, 318(1-2): 78–88

Luo S. J, Chen B G, Qi P X. Liquid Die Forging and Squeeze Casting Technology [M]. Beijing: Chemical Industry Press, 2007

Xu H, Zhang X, Liu Y P. Mechanical Property and Corrosion Behavior of SiCp/2A50 Composites Prepared by Liquid Forging[J]. Rare Metal Materials and Engineering, 2015, 44(6): 1307–1313

Murali S. Liquid Forging of Thin Al-Si Structures[J]. Journal of Materials Processing Technology, 2010, 210(10): 1276–1281

Kamga H.K, Larouche D. Hot Tearing of Aluminium-Copper B206 Alloys with Iron and Silicon Additions[J]. Materials Science and Engineering: A, 2010, 527(27-28): 7413–7423

Cao G, Kou S. Hot Cracking of Binary Mg-Al Alloy Castings[J]. Materials Science and Engineering: A, 2006, 417(1-2): 230–238

Wang Z.J, Huang Y H, Yang Y, et al. Atomic-Size Effect and Solid Solubility of Multicomponent Alloys[J]. Scripta Materialia, 2015, 94: 28–31

Tebib M, Samuel A M, Ajersch F, et al. Effect of P and Sr Additions on the Microstructure of Hypereutectic Al-15Si-14Mg-4Cu Alloy[J]. Materials Characterization, 2014, 89: 112–123

Morelock C.R, Gallington L C, Wilkinson A P. Solid Solubility, Phase Transitions, Thermal Expansion, and Compressibility in Sc1-xAlxF3[J]. Journal of Solid State Chemistry, 2015, 222: 96–102

Vintila R, Milligan J, Drew R A L, et al. Formation of Nanostructures and Solid Solubility Extension in Cryomilled Al-Cu and Al-Si Powders[J]. Canadian Metallurgical Quarterly, 2009, 48(1): 33–44

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the International Cooperation Project of the Ministry of Science and Technology of China (No. 2014DFR50320) and the National Natural Science Foundation of China (No. 51174064)

Rights and permissions

About this article

Cite this article

Sun, Y., Du, Z., Su, Y. et al. Effect of Zn/Mg/Cu Additions on Hot Cracking Tendency and Performances of Al-Cu-Mg-Zn Alloys for Liquid Forging. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 176–182 (2020). https://doi.org/10.1007/s11595-020-2241-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2241-5