Abstract

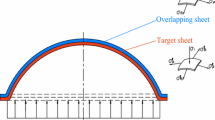

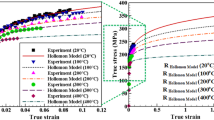

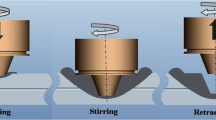

Aluminum alloy 5A02 with low plasticity was used as target sheet, and stainless steel SUS304 with good plasticity was used as overlapping sheet to investigate the effect of interface friction on bulging formability and microstructure of target sheet in overlapping sheets bulging process. Sheet sliding experiment was performed to measure interface friction coefficient of 5A02/SUS304 in different lubricating conditions and normal pressure. Overlapping sheets bulging experiment of 5A02/SUS304 was carried out to investigate the influence of interface friction on limit bulging height, wall thickness distribution, microstructure and fracture morphology of 5A02 bulging specimens. The results showed that increase of the interface friction coefficient of 5A02/SUS304 could effectively improve the limit bulging height and deformation uniformity of 5A02. And the fracture style of 5A02 transformed from toughness fracture of dimples-micropores gathered to fault slip separation fracture. Therefore, target sheet bulging formability is improved with the increase of interface friction coefficient.

Similar content being viewed by others

References

Lewandowski JJ, Lowhaphandu P. Effects of Hydrostatic Pressure on Mechanical Behaviour and Deformation Processing of Materials[J]. Int. Mater. Reviews, 1998, 43(4): 145–187

Smith LM, Ganeshmurthy S, Alladi K. Double-sided High-pressure Tubular Hydroforming[J]. J. Mater. Processing Technol., 2003, 142(3): 599–608

Wang Z, Wang ZJ. Infuence of Transverse Normal Pressure on Deformation Behavior of Sheet Metal[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2009, 24(S1): 174–178

Han HN, Kim KH. A Ductile Fracture Criterion in Sheet Metal Forming Process[J]. J. Mater. Processing Technol., 2003, 142(1): 231–238

Isik K, Silva MB, Tekkaya AE, et al. Formability Limits by Fracture in Sheet Metal Forming[J]. J. Mater. Processing Technol., 2014, 214(8): 1 557–1 565

Jain N, Wang J. Plastic Instability in Dual-pressure Tube-hydroforming Process[J]. Int. J. Mech. Sci., 2005, 47(12): 1 827–1 837

Liu DS, Manoharan M, Lewandowski JJ. Effects of Microstructure of the Behavior of an Aluminum Alloy and an Aluminum Matrix Composite Tested under Low Levels of Superimposed Hydrostatic Pres-sure[J]. Metallurgical and Mater. Transactions A, 1989, 20(11): 2 409–2 417

Semiatin SL, Piehler HR. Forming Limits of Sandwich Sheet Materi-als[J]. Metallurgical and Mater. Transactions A, 1979, 10(8): 1 107–1 118

Yoshida F, Hino R. Forming Limit of Stainless Steel-clad Aluminum Sheets under Plane Stress Condition[J]. J. Mater. Processing Technol., 1997, 63(1–3): 66–71

Yuan JW, Pang YH, Li T. Multilayer Clad Plate of Stainless Steel/aluminum/aluminum Alloy[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2011, 26(1): 111–113

Smith LM, Averill RC, Lucas JP, et al. Infuence of Transverse Normal Stress on Sheet Metal Formability[J]. Int. J. Plasticity, 2003, 19(10): 1 567–1 583

Matin PH, Smith LM. Practical Limitations to the Influence of Through-thickness Normal Stress on Sheet Metal Formability[J]. Int. J. Plasticity, 2005, 21(4): 671–690

Wang ZJ, Song H, Wang Z. Deformation Behavior of TC1 Titanium Alloy Sheet under Double-sided Pressure[J]. Trans. Nonferrous Met. Soc. China, 2008, 18(1): 72–76

Wang ZJ, Wang Z, Li MX. Failure Analysis of Al1060 Sheets under Double-Sided Pressure Deformation Conditions[J]. Key Eng. Mater., 2007, 353–358: 603–606

Wang Z, Lai XM, Wang ZJ, et al. Development of Experimental Method to Improve Sheet Metal Formability by Transverse Normal Stress[J]. Advanced. Mater. Research, 2011, 189–193: 2 949–2 956

Gao TJ, Liu Y, Chen P, et al. Analysis of Bulging Process of Aluminum Alloy by Overlapping Sheet Metal and its Formability[J]. Trans. Non-ferrous Met. Soc. China, 2015, 25(4): 1 050–1 055

Wang Y, Lang LH, Gao TJ, et al. Flow Property of AA2B06 Sheet Using Overlapping Elliptical Bulge Test[J]. Trans. Nonferrous Met. Soc. China, 2016, 26(8): 2 179–2 187

Wang Y, Lang L, Zafar R, et al. Investigation into the Overlapping Sheet Hydraulic Bulge and its Formability[J]. J. of the Brazilian Society of Mech. Sci. and Eng., 2016, 38(6): 1 635–1 645

Jia Z, Yang Y. Self-lubricating Properties of PTFE/serpentine Nano-composite against Steel at Different Loads and Sliding Velocities[J]. Composites Part B Eng., 2012, 43(4): 2 072–2 078

Beckford S, Mathurin L, Chen J, et al. The Effects of Polydopamine Coated Cu Nanoparticles on the Tribological Properties of Polydopa-mine/PTFE Coatings[J]. Tribology International, 2016, 103: 87–94

Kim HJ, Dong GS, Kim DE. Frictional Behavior between Silicon and Steel Coated with Graphene Oxide in Dry Sliding and Water Lubrication Conditions[J]. Int. J. Precision Eng. and Manufacturing-Green Technol., 2016, 3(1): 91–97

He LZ, Zhang HT, Cui JZ. Effects of Thermomechanical Treatment on the Mechanical Properties and Microstructures of 6013 Alloy[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2009, 24(2): 198–201

Song P, Wang XS. Influence of Axial Feeding on Hydroforming of Aluminum Alloy Tubular Part with Rectangular Section[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2009, 24(S1): 190–194

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No.51575364), the Program for Liaoning Innovation Talents in University (No. LR2017069), and the Shenyang Science and Technology Innovation Support Program for Young Talented People (No.RC180189)

Rights and permissions

About this article

Cite this article

Gao, T., Yao, Y., Wang, X. et al. Effect of Interface Friction on Overlapping Sheets Bulging Formability and Microstructure of 5A02 Aluminum Alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 919–924 (2019). https://doi.org/10.1007/s11595-019-2138-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2138-3