Abstract

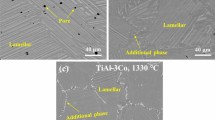

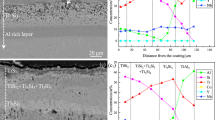

Si-Al-Y co-deposition coatings were prepared on Ti-Al alloy by pack cementation processes at 1 050 °C for 4 h with different halide activators in the packs for enhancing the high temperature oxidation resistance of Ti-Al alloy. The structure, constituent phases, formation process and oxidation behavior of the coatings were investigated. The experimental results showed that the coatings prepared respectively with NaF and NH4Cl as activators were composed of a (Ti, X)5Si4, (Ti, X)5Si3(X represents Nb and Cr), and TiSi2 outer layer, a TiAl2 inner layer and an Al-rich interdiffusion zone. However, the constituent phases changed into TiSi2 in the outer layer and (Ti, X)5Si4 and (Ti, X)5Si3 phases were observed in the middle layer of the coating prepared with AlCl3•6H2O activator. Among the halide activators studied, the coating prepared with AlCl3•6H2O was thicker and denser, which is the only suitable activator for pack Si-Al-Y co-deposition coatings on a Ti-Al alloy. The oxidation results show that the coating can protect the Ti-Al alloy from oxidation at 1000 °C in air for at least 80h. The excellent oxidation resistance of the coating is attributed to the formation of a dense scale mainly consisted of TiO2, SiO2 and Al2O3.

Similar content being viewed by others

References

Hua WX. Review of Alloy and Process Development of Ti-Al Alloys[J]. Intermetallics, 2006, 14: 1114–1122

W Kaysser. Surface Modifications in Aerospace Applications[J]. Surface engineering, 2001, 17: 305–312

Sun T, Sun LD, Wang Q, et al. Friction and Wear Properties of TiAl and Ti2AlN/TiAl Composites at High Temperature[J], Journal of Wuhan University of Technology-Materials Science Edition, 2013, 28: 1023–1028

Xiao ZX, Zheng LJ, Wang L, et al. Microstructure Evolution of Ti-47Al-2Cr-2Nb Alloys in the Liquid-metal-cooling (LMC) Directional-solidification Process[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2011, 26: 197–201

Zhang N, Lin JP, Wang YL. Influence of W, B, and Y Elements on Antioxidation of High Temperature and Long Term for Ti-Al Based Alloys with High Nb Content[J]. Rare Metal Materials and Engineering, 2007, 36: 884–887

Nicholls JR. Advances in Coating Design for High Performance Gas Turbines[J]. MRS Bulletin, 2003, 9: 659–670

Wu XQ, Xie FQ, Hu ZC, et al. Effects of Additives on Corrosion and Wear Resistance of Micro-arc Oxidation Coatings on Ti-Al Alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1032–1036

Brady MP, Brindley WJ, Smialek JL. The Oxidation and Protection of Gamma Titanium Aluminides[J]. JOM, 1996, 48: 46–50

Braun R, Maik F, Braue WF. Oxidation Behavior of Gamma Titanium Aluminizes with EB-PVD Thermal Barrier Coatings Exposed to Air at 900 ?[J]. Surface & Coatings Technology, 2007, 202: 676–680

Zhou W, Zhao YG, Qin QD. A New Way to Produce Al-Cr Coating on Ti Alloy by Vacuum Fusing Method and Its Oxidation Resistance[J]. Materials Science and Engineering A, 2006, 430: 254–259

Houng C, Chevalier S, Larpin JP. Synthesis and Characterisation of Pack Cemented Aluminize Coatings on Metals[J]. Applied Surface Science, 2004, 236: 256–269

Tsipas SA, Omar H, Perez FH, et al. Boroaluminide Coatings on Ferritic-martensitic Steel Deposited by Low-temperature Pack Cementation[J]. Surface & Coatings Technology, 2008, 202: 3263–3271

Lin NM, Xie FQ, Zhou J. Microstructures and Wear Resistance of Chromium Coatings on P110 Steel Fabricated by Pack Cementation[J]. Journal of Central South University of Technology, 2010, 17: 1144–1162

Tian XD, Guo XP. Structure and Oxidation Behavior of Si-Y co-deposition Coatings on an Nb Silicide Based Ultrahigh Temperature Alloy Prepared by Pack Cementation Technique[J]. Surface & Coatings Technology, 2009, 204: 313–318

Lin NM, Xie FQ, Wu XQ. Influence of Process Parameters on Thickness and Wear Resistance of Rare Earth Modified Chromium Coatings on P110 Steel Synthesized by Pack Cementation[J]. Journal of Rare Earths, 2011, 29: 396–340

Li YQ, Xie FQ, Wu XQ. Effects of Y2O3 on the Microstructures and Wear Resistance of Si-Al-Y Co-deposition Coatings Prepared on Ti-Al Alloy by Pack Cementation Technique[J]. Applied Surface Science, 2013, 287: 30–36

Li YQ, Xie FQ, Wu XQ. Microstructures and Wear Resistance of Si-Al-Y Co-deposition Coatings on Ti-Al Alloy[J]. Rare Metal Materials and Engineering, 2013, 42: 2257–2262

Ramos AS, Carlos AN, Gilberto CC. On the Peritectoid Ti3Si Formation in Ti-Si Alloys[J]. Materials Characterization, 2006, 56: 107–111

Kattner UR, Handwerker CA. Calculation of Phase Equilibrium in Candidate Solder Alloys[J]. Zeitschrift Fur Metallkunde, 2001, 92: 740–746

Majumdar S, Sharma I. Relationship between Pack Chemistry and Growth of Silicide Coatings on Mo-TZM Alloy[J]. Journal of The Electrochemical Society, 2008, 155: 734–741

Li X, Guo XP. Effects of Activators on Formation of Si-Zr-Y Co-deposition Coatings on Nb-Ti-Si-Cr based Ultrahigh Temperature Alloy[J]. Acta Metallurgica Sinica, 2012, 48: 1394–1402

Xiang ZD, Burnell JS, Datta PK. Aluminide Coating Formation on Nickel-base Superalloys by Pack Cementation Process[J]. Journal of Materials Science, 2001, 36: 5673–5682

Gong SK, Xu HB, Yu QH. Oxidation Behavior of TiAl/TiAl-SiC Gradient Coatings on Gamma Titanium Aluminides[J]. Surface & Coatings Technology, 2000, 130: 128–132

Tian XD, Guo XP. Oxidation Behavior of an Al-Modified Silicide Coating on an Nb-Silicide-Based Ultrahigh-Temperature Alloy[J]. Corrosion, 2010, 66: 025003–025009

Qi T, Guo XP. Microstructure and High Temperature Oxidation Resistance of Si-Y2O3 Co-deposition Coatings Prepared on an Nb-silicide-based Ultrahigh Temperature Alloy by Pack Cementation Process[J]. Journal of Inorganic Materials, 2009, 24: 1219–1225

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Key Scientific Research Projects in 2017 at North Minzu University(2017KJ05)

Rights and permissions

About this article

Cite this article

Li, Y., Xie, F. & Li, X. Si-Al-Y Co-deposition Coatings Prepared on Ti-Al Alloy for Enhanced High Temperature Oxidation Resistance. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 959–966 (2018). https://doi.org/10.1007/s11595-018-1919-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1919-4