Abstract

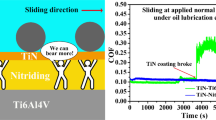

A duplex treatment of plasma Zr-alloying and plasma nitriding was used to improve the tribological properties of Ti-6Al-4V. The microstructure of the Zr-N composite (alloyed) layer formed on Ti-6Al-4V and its hardness, friction and wear properties were investigated by using OM, SEM, GDOES, EDS, microhardness tester as well as ball-on-disk tribometer. The results of microstructural analysis show that the alloyed layer is compact and uniform and is mainly composed of ZrN, TiN0.3 and AlN. A very tiny adhesive and slight oxidation wear is the primary wear mechanism for the modified Ti-6Al-4V. The tribological property is improved significantly after the duplex treatment. The good combination of antifriction and wear resistance for modified Ti-6Al-4V is mainly attributed to the higher surface hardness of metal nitrides formed on the surface and enhanced supporting of the Zr-diffusing layer.

Similar content being viewed by others

References

Bansal D G, Eryilmaz O L, Blaua P J. Surface Engineering to Improve the Durability and Lubricity of Ti6Al4V Alloy[J]. Wear, 2011, 271: 2006–2015

Chen Y K, Zheng X B, Xie Y T, et al. Antibacterial Properties of Vacuum Plasma Sprayed Titanium Coatings after Chemical Treatment[J]. Surf. Coat. Technol., 2009, 204: 685–690

Mello C B, Uedaa M, Silvac M M, et al. Tribological Effects of Plasma Immersion Ion Implantation Heating Treatments on Ti6Al4V Alloy[J]. Wear, 2009, 267: 867–873

Qu J, Lu X, Li D, et al. Silver/hydroxyapatite Composite Coatings on Porous Titanium Surfaces by Sol-gel Method[J]. J. Biomed. Mater. Res. B. Appl. Biomater., 2011, 97: 40–48

Jia Z F, Wang P, Xia Y Q, et al. Tribological Behaviors of Diamondlike Carbon Coatings on Plasma Nitrided Steel Using Three BN-containing Lubricants[J]. Appl. Surf. Sci., 2009, 255: 6666–6674

Grun R, Gunther H. Plasma Nitriding in Industry Problems, New Solutions and Limits[J]. Mater. Sci. Eng., 1991, 140: 435–441

Yerramareddy S, Bahadur S. Effect of Operational Variables, Microstructure and Mechanical Properties on the Erosion of Ti6Al4V[J]. Wear, 1991, 142: 253–263

Tian Y S, Chen C Z, Chen L B, et al. Wear Properties of Alloyed Layers Produced by Laser Surface Alloying of Pure Titanium with B4C and Ti Mixed Powders[J]. J. Mater. Sci., 2005, 40: 4387–4390

Budinski K G. Tribological Properties of Titanium Alloys[J]. Wear, 1991, 151: 203–217

Wang Z X, He Z Y, Wang Y Q, et al. Microstructure and Tribological Behaviors of Ti6Al4V Alloy Treated by Plasma Ni Alloying[J]. Appl. Surf. Sci., 2011, 257: 10267–10272

Alonso F, Rinner M, Loinaz A, et al. Characterization of Ti-6Al-4V Modified by Nitrogen Plasma Immersion Ion Implantation[J]. Surf. Coat. Technol, 1997, 93: 305–308

Fukumoto S, Tsubakino H, Inoue S. Surface Modification of Titanium by Nitrogen Ion Implantation[J]. Mater. Sci. Eng., 1999, 263: 205–209

Han S H, Kim H D, Lee Y, et al. Plasma Source Ion Implantation of Nitrogen, Carbon and Oxygen into Ti-6Al-4V Alloy[J]. Surf. Coat. Technol., 1996, 82: 270–276

Khaled M, Yilbas B S, Shirokoff J. Electrochemical Study of Laser Nitrided and PVD TiN Coated Ti-6Al-4V Alloy: the Observation of Selective Dissolution[J]. Surf. Coat. Technol, 2001, 148: 46–54

Lim S H N, McCulloch D G, Russo S, et al. Using PVD and a Plasma Immersion Ion Implantation System[J]. Nucl. Instrum. Methods B, 2002, 190: 723–727

Yilbas B S, Hashmi M S J, Shuja S Z. Laser Treatment and PVD TiN Coating of Ti-6Al-4V Alloy[J]. Surf. Coat. Technol., 2001, 140: 244–250

Chou W J, Yu G P, Huang J H. Corrosion Resistance of ZrN Films on AISI 304 Stainless Steel Substrate[J]. Surf. Coat. Technol., 2003, 167: 59–67

Pilloud D, Dehlinger A S, Pierson J F, et al. Reactively Sputtered Zirconium Nitride Coatings: Structural, Mechanical, Optical and Electrical Characteristics[J]. Surf. Coat. Technol., 2003, 174: 338–344

Atar E, Sabri E K, Cimenoglu H. Sliding Wear Behaviour of ZrN and (Zr, 12 wt%Hf)N Coatings[J]. Tribol. Int., 2006: 297–302

Budke E, Krempel-Hesse J, Maidhof H, et al. Decorative Hard Coatings with Improved Corrosion Resistance[J]. Surf. Coat. Technol., 1999, 112: 108–113

Ramos H J, Valmoria N B. Thin-film Deposition of ZrN Using a Plasma Sputter-type Negative Ion Source[J]. Vacuum, 2004, 73: 549–554

Lo’pez G., Staia M H. High-temperature Tribological Characterization of Zirconium Nitride Coatings[J]. Surf. Coat. Technol., 2005, 200: 2092–2099

Brugnoni C, Lanza F, Macchi G, et al. Evaluation of the Wear Resistance of ZrN Coatings Using Thin Layer Activation[J]. Surf. Coat. Technol., 1998, 100: 23–26

Piscanec S, Ciacchi L C, Vesselli E, et al. Bioactivity of TiN-coated Titanium Implants[J]. Acta. Mater., 2004, 52: 1237–1245

Lakshmi S G, Arivuoli D, Ganguli B. Surface Modification and Characterisation of Ti-Al-V Alloys[J]. Mater. Chem. Phys., 2002, 76: 187–190

Bell T, Bergmann H W, Lanagan J, et al. Surface Engineering of Titanium with Nitrogen[J]. Surf. Eng., 1986, 2: 133–143

Xu Z, Liu X P, Zhang P Z. Double Glow Plasma Surface Alloying and Plasma Nitriding[J]. Surf. Coat. Technol., 2007, 201: 4822–4825

Majumdar P, Singh S B, Chakraborty M. Wear Response of Heattreated Ti-13Zr-13Nb Alloy in Dry Condition and Simulated Body Fluid[J]. Wear, 2008, 264: 1015–1025

Xu Z. Method and Apparatus for Introducing Normally Solid Materials into Substrate Surface[P]. U.S. Patent, No. 4, 520, 268 1985

Kolachev B A, Egorova B Y, Belova S B. Relation between the Temperature of the a+ß-ß Transformation of Commercial Titanium Alloys and Their Chemical Composition[J]. Met. Sci. Heat Treat., 2008, 50: 367–373

Nagasaki S, Hirabayashi M. Binary Alloy Phase Diagrams[M]. Beijing: Metallurgical Industry Press, 2004

Yildiz F, Yetim A F, Alsaran A, et al. Wear and Corrosion Behavior of Various Surface Treated Medical Grade Titanium Alloy in Biosimulated Environment[J]. Wear, 2009, 267: 695–701

Borgioli F, Galvanetto E, Fossati A, et al. Glow-discharge and Furnace Treatments of Ti-6Al-4V[J]. Surf. Coat. Technol., 2004, 184: 255–262

Bhushan B. Introduction to Tribology[M]. New York: Willy, 2007

Li X Y, Tang B, Wang H F, et al. Zr-N Surface Alloying Layers Fabricated in Pure Titanium Substrates by Plasma Surface Alloying[J] Trans. Nonferrous Met. Soc., 2013, 23: 1628–1632

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (Nos.51474154,51401141,51501125) and the Provincial Natural Science Foundation of Shanxi (Nos.2014011015-7, 2014021017-3)

Rights and permissions

About this article

Cite this article

Chen, K., Liu, X., Liu, X. et al. Microstructure and wear behavior of Ti-6Al-4V treated by plasma Zr-alloying and plasma nitriding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 1086–1092 (2016). https://doi.org/10.1007/s11595-016-1494-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1494-5