Abstract

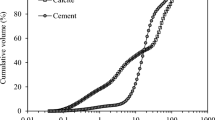

The rheological behaviors of fresh cement paste with polycarboxylate superplasticizer were systematically investigated. Influential factors including superplasticizer to cement ratio (Sp/C), water to cement ratio (w/c), temperature, and time were discussed. Fresh cement pastes with Sp/Cs in the range of 0 to 2.0% and varied W/Cs from 0.25 to 0.5 were prepared and tested at 0, 20 and 40 °C, respectively. Flowability and rheological tests on cement pastes were conducted to characterize the development of the rheological behavior of fresh cement pastes over time. The exprimental results indicate that the initial flowability and flowability retention over shelf time increase with the growth in superplasticizer dosage due to the plasticizing effect and retardation effect of superplasticizer. Higher temperature usually leads to a sharper drop in initial flowability and flowability retention. However, for the cement paste with high Sp/C or w/c, the flowability is slightly affected by temperature. Yield stress and plastic viscosity show similar variation trends to the flowability under the abovementioned influential factors at low Sp/C. In the case of high Sp/C, yield stress and plastic viscosity start to decline over shelf time and the decreasing rate descends at elevated temperature. Moreover, two equations to roughly predict yield stress and plastic viscosity of the fresh cement pastes incorporating Sp/C, w/c, temperature and time are developed on the basis of the existing models, in which experimental constants can be extracted from a database created by the rheological test results.

Similar content being viewed by others

References

Zhao Z, Tang WD, Zhang P. Research on Test Method for Workability of High Flowability Concrete[J]. Build. Sci., 2006, 22: 51–55

Ferraris CF, Obla KH, Hill R. The Influence of Mineral Admixtures on the Rheology of Cement Paste and Concrete[J]. Cem. Concr. Res., 2001, 31(2): 245–255

Zhang Y, Kong X, Hou S, et al. Study on the Rheological Properties of Fresh Cement Asphalt Paste[J]. Constr. Build. Mater., 2012, 27(1): 534–544

Zingg A, Winnefeld F, Holzer L, et al. Adsorption of Polyelectrolytes and Its Influence on the Rheology, Zeta Potential, and Microstructure of Various Cement and Hydrate Phases[J]. J. Colloid Interface Sci., 2008, 323(2): 301–312

Flatt RJ. Towards A Prediction of Superplasticized Concrete Rheology[J]. Mater. Struct., 2004, 37(5): 289–300

Houst YF, Bowen P, Perche F, et al. Design and Function of Novel Superplasticizers for More Durable High Performance Concrete (Superplast Project)[J]. Cem. Concr. Res., 2008, 38(10): 1197–1209

Han S, Yan PY, Kong XM. Study on the Compatibility of Cement-Superplasticizer System Based on the Amount of Free Solution[J]. Sci. China Technol. Sc., 2011, 54(1): 183–189

Daimon M, Roy DM. Rheological Properties of Cement Mixes: II. Zeta Potential and Preliminary Viscosity Studies[J]. Cem. Concr. Res., 1979, 9(1): 103–109

Lei L, Plank J. Synthesis, Working Mechanism and Effectiveness of A Novel Cycloaliphatic Superplasticizer for Concrete[J]. Cem. Concr. Res., 2012, 42(1): 118–123

Golaszewski J, Szwabowski J. Influence of Superplasticizers on Rheological Behavior of Fresh Cement Mortars[J]. Cem. Concr. Res., 2004, 34(2): 235–248

Romano RCDO, Pileggi RG. Temperture Influence on the Rheological Behaviour of Cementitous Pastes Prepared with Air-entraining Admixtures[J]. Appl. Rheol., 2012, 22(2): 24333–24338

Petit JY, Wirquin E, Duthoit B. Influence of Temperature on the Yield Value of Highly Flowable Micromortars Made with Sulfonate-based Superplasticizer[J]. Cem. Concr. Res., 2005, 35(2): 256–266

Petit JY, Khayat KH, Wirquin E. Coupled Effect of Time and Temperature on Variations of Yield Value of Highly Flowable Mortar[J]. Cem. Concr. Res., 2006, 36(5): 832–841

Petit JY, Wirquin E, Vanhove Y, et al. Yield Stress and Viscosity Equations for Mortars and Self-consolidating Concrete[J]. Cem. Concr. Res., 2007, 37(5): 655–670

Petit JY, Khayat KH, Wirquin E. Coupled Effect of Time and Temperature on Variations of Plastic Viscosity of Highly Flowable Mortar[J]. Cem. Concr. Res., 2009, 39(3): 165–170

Petit JY, Wirquin E, Khayat KH. Effect of Temperature on the Rheology of Flowable Mortars[J]. Cem. Concr. Compos., 2010, 32(1): 43–53

Nehdi M, Martini SA. Estimating Time and Temperature Dependent Yield Stress of Cement Paste using Oscillatory Rheology and Genetic Algorithms[J]. Cem. Concr. Res., 2009, 39(11): 1007–1016

Struble L, Sun GK. Viscosity of Portland Cement Paste as A Function of Concentration[J]. Adv. Cem. Based Mater., 1995, 2(2): 62–69

Flatt RJ, Bowen P. Yodel: A Yield Stress Model for Suspensions[J]. J. Am. Ceram. Soc., 2006, 89(4): 1244–1256

Flatt RJ, Bowen P. Yield Stress of Multimodal Powder Suspensions: An Extension of the YODEL (Yield Stress Model)[J]. J. Am. Ceram. Soc., 2007, 90(4): 1038–1044

Kong XM, Zhang YR, Hou SS. Study on the Rheological Properties of Portland Cement Pastes with Polycarboxylate Superplasticizers[J]. Rheol. Acta, 2013, 52(7): 707–718

Banfill PFG. Rheology of Fresh Cement and Concrete[J]. Br. Soc. Rheol., 2006, (2006): 61–130

Sakai E, Kasuga T, Sugiyama T, et al. Influence of Superplasticizers on the Hydration of Cement and the Pore Structure of Hardened Cement[J]. Cem. Concr. Res., 2006, 36(11): 2049–2053

Zhou Z, Solomon MJ, Scales P, et al. The Yield Stress of Concentrated Flocculated Suspensions of Size Distributed Particles[J]. J. Rheol., 1999, 43(3): 651–671

Mollah MYA, Adams WJ, Schennach R, et al. A Review of Cement–superplasticizer Interactions and Their Models[J]. Adv. Cem. Res., 2000, 12(4): 153–161

Jansen D, Neubauer J, Goetz-Neunhoeffer F, et al. Change in Reaction Kinetics of A Portland Cement Caused by A Superplasticizercalculation of Heat Flow Curves from XRD Data[J]. Cem. Concr. Res., 2012, 42(2): 327–332

Cheung J, Jeknavorian A, Roberts L, et al. Impact of Admixtures on the Hydration Kinetics of Portland Cement[J]. Cem. Concr. Res., 2011, 41(12): 1289–1309

Plank J, Zhimin D, Keller H, et al. Fundamental Mechanisms for Polycarboxylate Intercalation into C3A Hydrate Phases and the Role of Sulfate Present in Cement[J]. Cem. Concr. Res., 2010, 40(1): 45–57

Flatt RJ, Houst YF. A Simplified View on Chemical Effects Perturbing the Action of Superplasticizers[J]. Cem. Concr. Res., 2001, 31(8): 1169–1176

Hansen FP, Pederson EJ. Curing of Concrete Structures, Draft DEBGuide to Durable Concrete Structures[M]. Switzerland, 1985

Pane I, Hansen W. Concrete Hydration and Mechanical Properties under Nonisothermal Conditions[J]. ACI Mater. J., 2002, 99(6): 534–542

Mills RH. Factors Influencing Cessation of Hydration in Water Cured Cement Pastes[C]. In: Proceedings of the Symposium on the Structure of Portland Cement Paste and Concrete, Highway Research Board, Washington DC, 1966

Hansen PF, Pedersen EJ. Maturity Computer for Controlled Curing and Hardening of Concrete[R]. 1977

Chanvillard G, Daloia L. Concrete Strength Estimation at Early Age: Modification of the Method of Equivalent Age[J]. ACI Mater. J., 1997, 94(6): 220–227

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by the National Natural Science Foundation of China (Nos. U1301241 and U1234211) and the Postdoctoral Science Foundation of China (No. 2015M580042)

Rights and permissions

About this article

Cite this article

Zhang, Y., Kong, X., Gao, L. et al. Rheological behaviors of fresh cement pastes with polycarboxylate superplasticizer. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 286–299 (2016). https://doi.org/10.1007/s11595-016-1366-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1366-z