Abstract

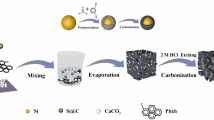

Silicon (Si) is a promising anode material for next-generation lithium-ion batteries (LIBs) with its high theoretical specific capacity (4200 mAh/g). However, Si anode has a huge volume change rate (> 300%) and high cost compared to graphite, which limits the commercial application of Si anode. Carbon coating can effectively tackle the volume change and poor conductivity during cycling of Si anode. In this work, aluminum–silicon alloy was firstly etched by hydrochloric acid. Followed by a mixture with pyrolysis of phenolic resin, the carbon layer outside the silicon particles was deposited during heat treatment process. The carbon-coated porous silicon-carbon (Si/C) anode material demonstrates excellent electrochemical performance and porous structure, which relieves mechanical stress and inhibits volume expansion. The results show that Si/C present well electrochemical performance at a sintering temperature of 800 ℃. Specially, the Si/C anode delivers a high specific capacity of 1394.4 mAh/g at the current density of 0.5 A/g with 46.1% retention. Nitrogen-doped silicon carbon composite material (Si/NC) was synthesized to further improve the performance of Si/C anodes. The characterizations confirm good crystallinity, uniform carbon coating on silicon surfaces, and even distribution of Si, C, and N elements. Simultaneously, a highly stable reversible capacity of 1218.3 mAh/g with 42.7% retention over 300 cycles at a current density of 0.5 A/g was obtained. This research can provide an alternative approach for high-energy and low-cost silicon-based anodes for LIBs.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Gong H, Hansen TJEI et al (2023) The rise of China’s new energy vehicle lithium-ion battery industry: the coevolution of battery technological innovation systems and policies. Environ Innov Soc Trans 46:100689. https://doi.org/10.1016/j.eist.2022.100689

Wu Y, Wang W et al (2019) An exploration of new energy storage system: high energy density, high safety, and fast charging lithium ion battery. Adv Funct Mater 29(1):1805978. https://doi.org/10.1002/adfm.201805978

Li J, Ku Y et al (2020) Dual credit policy: promoting new energy vehicles with battery recycling in a competitive environment? J Clean Prod 243:118456. https://doi.org/10.1016/j.jclepro.2019.118456

Wang N, Tang GJS (2022) A review on environmental efficiency evaluation of new energy vehicles using life cycle analysis. Sustainability 14(6):3371. https://doi.org/10.3390/su14063371

Fan L, Ma R et al (2019) Graphite anode for a potassium-ion battery with unprecedented performance. Angew Chem Int Ed 58(31):10500–10505. https://doi.org/10.1002/anie.201904258

Chen K-H, Namkoong MJ et al (2020) Efficient fast-charging of lithium-ion batteries enabled by laser-patterned three-dimensional graphite anode architectures. J Power Sources 471:228475. https://doi.org/10.1016/j.jpowsour.2020.228475

Tang J, Wu F et al (2023) Robust MXene adding enables the stable interface of silicon anodes for high-performance Li-ion batteries. Chem Eng J 452:139139. https://doi.org/10.1016/j.cej.2022.139139

Chen H, Wu Z et al (2021) A mechanically robust self-healing binder for silicon anode in lithium ion batteries. Nano Energy 81:105654. https://doi.org/10.1016/j.nanoen.2020.105654

Wang Q, Meng T et al (2021) Consecutive chemical bonds reconstructing surface structure of silicon anode for high-performance lithium-ion battery. Energy Storage Mater 39:354–364. https://doi.org/10.1016/j.ensm.2021.04.043

Jiao X, Yin J et al (2021) Highly energy-dissipative, fast self-healing binder for stable Si anode in lithium-ion batteries. Adv Func Mater 31(3):2005699. https://doi.org/10.1002/adfm.202005699

Chen X, Li H et al (2019) Structure design and mechanism analysis of silicon anode for lithium-ion batteries. Sci China Mater 62(11):1515–1536. https://doi.org/10.1007/s40843-019-9464-0

Li Z, Wan Z et al (2021) A robust network binder via localized linking by small molecules for high-areal-capacity silicon anodes in lithium-ion batteries. Nano Energy 79:105430. https://doi.org/10.1016/j.nanoen.2020.105430

Sun L, Liu Y et al (2022) A review on recent advances for boosting initial coulombic efficiency of silicon anodic lithium ion batteries. Small 18(5):2102894. https://doi.org/10.1002/smll.202102894

Azam MA, Safie NE et al (2021) Recent advances of silicon, carbon composites and tin oxide as new anode materials for lithium-ion battery: a comprehensive review. A comprehensive review. J Energy Storage 33:102096. https://doi.org/10.1016/j.est.2020.102096

Hou G, Cheng B et al (2019) Multiscale buffering engineering in silicon–carbon anode for ultrastable Li-ion storage. ACS Nano 13(9):10179–10190. https://doi.org/10.1021/acsnano.9b03355

An Y, Tian Y et al (2020) Porosity-and graphitization-controlled fabrication of nanoporous silicon@ carbon for lithium storage and its conjugation with MXene for lithium-metal anode. Adv Func Mater 30(9):1908721. https://doi.org/10.1002/adfm.201908721

Qin Y, Li Q et al (2017) CoO-Co nanocomposite anode with enhanced electrochemical performance for lithium-ion batteries. Electrochim Acta 224:90–95. https://doi.org/10.1016/j.electacta.2016.12.040

Wang F, Chen G et al (2019) Engineering of carbon and other protective coating layers for stabilizing silicon anode materials. Carbon Energy 1(2):219–245. https://doi.org/10.1002/cey2.24

Liu XH, Zhong L et al (2012) Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6(2):1522–1531. https://doi.org/10.1021/nn204476h

Ashuri M, He Q et al (2020) Improving cycle stability of Si anode through partially carbonized polydopamine coating. J Electroanal Chem 876:114738. j.jelechem.2020.114738

Ashuri M, He Q et al (2017) Synthesis of hollow silicon nanospheres encapsulated with a carbon shell through sol–gel coating of polystyrene nanoparticles. J Sol-Gel Sci Technol 82:201–213. https://doi.org/10.1007/s10971-016-4265-z

Mu T, Xiang L et al (2022) Ultrahigh areal capacity silicon anodes realized via manipulating electrode structure. Energy Storage Mater 53:958–968. https://doi.org/10.1016/j.ensm.2022.10.021

Qi J, Yu X et al (2023) Enhanced cycling stability and rate capability of silicon/graphite anodes by chitosan-based aqueous binder. Ionics 29(3):951–961. https://doi.org/10.1007/s11581-022-04877-w

Dong H, Wang J et al (2022) Exploring the practical applications of silicon anodes: a review of silicon-based composites for lithium-ion batteries. Ionics 28(7):3057–3077. https://doi.org/10.1007/s11581-022-04622-3

Mu T, Zuo P et al (2018) A two-dimensional nitrogen-rich carbon/silicon composite as high performance anode material for lithium ion batteries. Chem Eng J 341:37–46. https://doi.org/10.1016/j.cej.2018.02.026

Wang H, Fu J et al (2020) A binder-free high silicon content flexible anode for Li-ion batteries. Energy Environ Sci 13(3):848–858. https://doi.org/10.1039/c9ee02615k

Zhu R, Wang Z et al (2021) Silicon in hollow carbon nanospheres assembled microspheres cross-linked with N-doped carbon fibers toward a binder free, high performance, and flexible anode for lithium-ion batteries. Adv Func Mater 31(33):2101487. https://doi.org/10.1002/adfm.202101487

Fan X, Cai T et al (2023) Carbon nanotube-reinforced dual carbon stress-buffering for highly stable silicon anode material in lithium-ion battery. Small 19(30):2300431. https://doi.org/10.1002/smll.202300431

Mu T, Sun Y et al (2022) Long-life silicon anodes by conformal molecular-deposited polyurea interface for lithium ion batteries. Nano Energy 103:107829. https://doi.org/10.1016/j.nanoen.2022.107829

Gu L, Han J et al (2022) Enabling robust structural and interfacial stability of micron-Si anode toward high-performance liquid and solid-state lithium-ion batteries. Energy Storage Mater 52:547–561. https://doi.org/10.1016/j.ensm.2022.08.028

Fan Z, Zheng S et al (2020) Preparation of micron Si@ C anodes for lithium ion battery by recycling the lamellar submicron silicon in the kerf slurry waste from photovoltaic industry. Diam Relat Mater 107:107898. https://doi.org/10.1016/j.diamond.2020.107898

Feng K, Li M et al (2019) Micron-sized secondary Si/C composite with in situ crosslinked polymeric binder for high-energy-density lithium-ion battery anode. Electrochim Acta 309:157–165. https://doi.org/10.1016/j.electacta.2019.04.033

Jo M, Sim S et al (2022) Micron-sized SiOx-graphite compound as anode materials for commercializable lithium-ion batteries. Nanomaterials 12(12):1956. https://doi.org/10.3390/nano12121956

Nandan R, Takamori N et al (2022) Black glasses grafted micron silicon: a resilient anode material for high-performance lithium-ion batteries. J Mater Chem A 10(30):15960–15974. https://doi.org/10.1039/d2tă8c

Luo Y, Huang L et al (2022) The optimization of porosity and particle size for micron-size porous silicon in high energy pre-lithiated silicon-graphite composite for Li-ion batteries. Microporous Mesoporous Mater 331:111672. https://doi.org/10.1016/j.micromeso.2021.111672

Zhao F, Zhao M et al (2022) Facile preparation of micron-sized silicon-graphite-carbon composite as anode material for high-performance lithium-ion batteries. Powder Technol 404:117455. https://doi.org/10.1016/j.powtec.2022.117455

Jiang H, Wang J et al (2012) The pyrolysis mechanism of phenol formaldehyde resin. Polym Degrad Stab 97(8):1527–1533. https://doi.org/10.1016/j.polymdegradstab.2012.04.016

Li P, Miao C et al (2023) Pomegranate like silicon–carbon composites prepared from lignin-derived phenolic resins as anode materials for lithium-ion batteries. New J Chem 47(36):16855–16863. https://doi.org/10.1039/d3nj02547k

Chen J, Wang J et al (2023) Si nanoparticles confined in N, P-doped double carbon as efficient anode materials for lithium ion batteries. J Alloy Compd 935:167850. https://doi.org/10.1016/j.jallcom.2022.167850

Li Y, Tian Y et al (2023) Multi-functional double carbon shells coated boron-doped porous Si as anode materials for high-performance lithium-ion batteries. Electrochim Acta 462:142712. https://doi.org/10.1016/j.electacta.2023.142712

Hong F, Zhou R et al (2023) Fabrication of porous SiOx/nanoSi@ C composites with homogeneous silicon distribution for high-performance Li-ion battery anodes. J Alloy Compd 947:169511. https://doi.org/10.1016/j.jallcom.2023.169511

Zhu L, Chen Y et al (2020) Double-carbon protected silicon anode for high performance lithium-ion batteries. J Alloy Compd 812:151848. https://doi.org/10.1016/j.jallcom.2019.151848

Zhang W, Chen J et al (2021) Electronic and mechanical properties of monocrystalline silicon doped with trace content of N or P: A first-principles study. Solid State Sci 120:106723. https://doi.org/10.1016/j.solidstatesciences.2021.106723

Duan H, Xu H et al (2023) Silicon/graphite/amorphous carbon as anode materials for lithium secondary batteries. Molecules 28(2):464. https://doi.org/10.3390/molecules28020464

Funding

This work was financially supported by the National Natural Science Foundation of China (21501015, 21545010, 31527803), Hunan Provincial Key Laboratory of Materials Protection for Electric Power and Transportation (2022CL01), and Hunan Provincial Natural Science Foundation of China (2022JJ30604).

Author information

Authors and Affiliations

Contributions

Z.X: experiments, characterization, manuscript writing, and revising. Y.X and C.W: XRD, XPS data analysis, SEM/TEM analysis, and TGA analysis. L.S and Q.Y: experimental planning, manuscript preparation, and funding. M.X and X.P: Raman spectroscopy and electrochemical analysis. T.Z: validation, writing, review, and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, Z., Xia, Y., Wang, C. et al. Preparation and properties of porous silicon anode coated with nitrogen-doped carbon for lithium-ion battery. Ionics (2024). https://doi.org/10.1007/s11581-024-05524-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11581-024-05524-2