Abstract

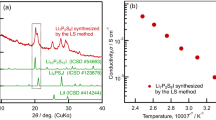

The Pr3+, Sm3+, and Gd3+ triple-doped ceria Ce0.76Pr0.08Sm0.08Gd0.08O2-δ material as solid electrolyte for IT-SOFC has been successfully synthesized by sol–gel auto-combustion route. The effect of microwave sintering (1300 °C for 15, 30, and 60 min, named as PSG-MS15, PSG-MS30, and PSG-MS60, respectively) on structural, electrical, and thermal properties of prepared electrolyte material has been studied. Powder X-ray diffraction, scanning electron microscope, energy dispersive spectroscopy, and Raman analysis revealed the single phase, microstructure, elemental confirmation, and structural oxygen vacancy formation of all the samples. Impedance spectroscopy analysis revealed the highest total ionic conductivity, i.e., 3.47 × 10−2 S cm−1 at 600 °C with minimum activation energy of 0.69 eV, in PSG-MS30 sample when compared to PSG-MS15 and PSG-MS60. The thermal expansion measurements have been carried out for PSG-MS30 specimen. The highest total ionic conductivity with minimum activation energy and moderate thermal expansion coefficient of PSG-MS30 sample makes the possibility of its use as solid electrolyte in IT-SOFC applications.

Similar content being viewed by others

References

Stambouli B, Traversa E (2002) Solid oxide fuel cells (SOFCs): a review of an environmentally clean and efficient source of energy. Renew Sust Energ Rev 6(5):433–455. https://doi.org/10.1016/S1364-0321(02)00014-X

Minh NQ (1993) Ceramic Fuel Cells. J Am Ceramic Soc 76(3):563–588. https://doi.org/10.1111/j.1151-2916.1993.tb03645.x

Inaba H, Tagawa H (1996) Ceria-based solid electrolytes. Solid State Ionics 83(1-2):1–16. https://doi.org/10.1016/0167-2738(95)00229-4

Bhabu KA, Theerthagiri J, Madhavan J, Balu T, Muralidharan G, Rajasekaran TR (2016) Cubic fluorite phase of samarium doped cerium oxide (CeO2)0.96Sm0.04 for solid oxide fuel cell electrolyte. J Mater Sci Mater Electron 27(2):1566–1573. https://doi.org/10.1007/s10854-015-3925-z

Ahmed SI, Mohammed T, Bahafi A, Suresh MB (2017) Effect of Mg doping and sintering temperature on structural and morphological properties of samarium-doped ceria for IT-SOFC electrolyte. Appl Nanosci 7(5):243–252. https://doi.org/10.1007/s13204-017-0567-x

Dikmen S, Aslanbay H, Dikmen E, Sahin O (2010) Hydrothermal preparation and electrochemical properties of Gd3+ and Bi3+, Sm3+, La3+, and Nd3+codoped ceria-based electrolytes for intermediate temperature-solid oxide fuel cell. J Power Sources 195(9):2488–2495. https://doi.org/10.1016/j.jpowsour.2009.11.077

Tadokoro SK, Muccillo ENS (2007) Effect of Y and Dy co-doping on electrical conductivity of ceria ceramics. J Eur Ceramic Soc 27(13-15):4261–4264. https://doi.org/10.1016/j.jeurceramsoc.2007.02.138

Pikalova EY, Murashkina AA, Maragou VI, Demin AK, Strekalovsky VN, Tsiakaras PE (2011) CeO2 based materials doped with lanthanides for applications in intermediate temperature electrochemical devices. Int J Hydrog Energy 36(10):6175–6183. https://doi.org/10.1016/j.ijhydene.2011.01.132

Ji B, Tian C, Wang C, Wu T, Xie J, Li M (2015) Preparation and characterization of Ce0.8Y0.2 − xCuxO2 − δ as electrolyte for intermediate temperature solid oxide fuel cells. J Power Sources 278:420–429. https://doi.org/10.1016/j.jpowsour.2014.12.073

Ramesh S, James Raju KC (2012) Preparation and characterization of Ce1 − x(Gd0.5Pr0.5)xO2 electrolyte for IT-SOFCs. Int J Hydrog Energy 37(13):10311–10317. https://doi.org/10.1016/j.ijhydene.2012.04.008

Xiaomin L, Qiuyue L, Lili Z, Xiaomei L (2015) Synthesis and characterization of Ce0.8Sm0.2 − xPrxO2 − δ (x = 0.02–0.08) solid electrolyte materials. J Rare Earths 33(4):411–416. https://doi.org/10.1016/S1002-0721(14)60434-8

Wang FY, Wan BZ, Cheng S (2005) Study on Gd3+ and Sm3+ co-doped ceria electrolytes. J Solid State Electrochem 9(3):168–173. https://doi.org/10.1007/s10008-004-0575-0

Anderson DA, Simak SI, Skorodumova NV, Abrikosov IA, Johansson B (2006) Optimization of ionic conductivity in doped ceria. PANS 103:3518–3521. https://doi.org/10.1073/pnas.0509537103

Rai A, Mehta P, Omar S (2014) Conduction behavior in SmxNd0.15 − xCe0.85O2 − δ. Solid State Ionics 263:190–196. https://doi.org/10.1016/j.ssi.2014.06.009

Anirban S, Dutta A (2016) Microstructure and charge carrier dynamics in Pr-Sm-Eu triple-doped nanoceria. Solid State Ionics 295:48–56. https://doi.org/10.1016/j.ssi.2016.07.008

Babu AS, Bauri R, Srinivas Reddy G (2016) Processing and conduction behavior of nanocrystalline Gd-doped and rare earth co-doped ceria electrolytes. Electrochim Acta 209:541–550. https://doi.org/10.1016/j.electacta.2016.05.118

Venkataramana K, Madhuri C, Suresh Reddy Y, Bhikshamaiah G, Vishnuvardhan Reddy C (2017) Structural, electrical and thermal expansion studies of tri-doped ceria electrolyte materials for IT-SOFCs. J. Alloys Compd 719:97–107. https://doi.org/10.1016/j.jalcom.2017.05.022

Boskovic S, Zec S, Brankovic G, Brankovic Z, Devecerski A, Matovic B, Aldinger F (2010) Preparation, sintering and electrical properties of nano-grained multi doped ceria. Ceram Int 36(1):121–127. https://doi.org/10.1016/j.ceramint.2009.07.015

Stojmenovic M, Boskovic S, Bucevac D, Prekajski M, Babic B, Matovic B (2013) Electrical characterization of multi doped ceria ceramics. Ceram Int 39(2):1249–1255. https://doi.org/10.1016/j.ceramint.2012.07.055

Stojmenovic M, Boskovic S, Zunic M, Varela JA, Prekajski M, Matovic B, Mentus S (2014) Electrical properties of multi doped ceria. Ceram Int 40(7):9285–9292. https://doi.org/10.1016/j.ceramint.2014.01.151

Muhammed Ali SA, Anwar M, Abdalla AM, Somalu MR, Muchtar A (2017) Ce0.80Sm0.10Ba0.05Er0.05O2 − δ multi-doped ceria electrolyte for intermediate temperature solid oxide fuel cells. Ceram Int 43(1):1265–1271. https://doi.org/10.1016/j.ceramint.2016.10.075

Oghbaei M, Mirzae O (2010) Microwave versus conventional sintering: a review of fundamentals, advantages and applications. J Alloys Compounds 494(1-2):175–189. https://doi.org/10.1016/j.jallcom.2010.01.068

Gonjal JP, Heuguet R, Gil DM, Calzada AR, Marinel S, Moran E, Schmidt R (2015) Microwave synthesis & sintering of Sm and Ca co-doped ceria ceramics. Int J Hydrog Energy 40(45):15640–15651. https://doi.org/10.1016/j.ijhydene.2015.07.161

Cesario MR, Savary E, Marinel S, Raveau B, Caignaert V (2016) Synthesis and electrochemical performance of Ce1 − xYbxO2 − x/2 solid electrolytes: the potential of microwave sintering. Solid State Ionics 294:67–72. https://doi.org/10.1016/j.ssi.2016.07.005

Prekajski M, Stojmenovic M, Radojkovic A, Brankovic G, Oraon H, Subasri R, Matovic B (2014) Sintering and electrical properties of Ce1 − xBixO2 − δ solid solution. J Alloys Compounds 617:563–568. https://doi.org/10.1016/j.jallcom.2014.08.090

Venkataramana K, Ravindranath K, Madhuri C, Madhusudan C, Kumar NP, Reddy CV (2017) Low temperature microwave sintering of yttrium and samarium co-doped ceria solid electrolytes for IT-SOFCs. Ionics. https://doi.org/10.1007/s11581-017-2293-5

Askrabic A, Dohcevic-Mitrovic ZD, Radovic M, scepanovic M, Popovic ZV (2009) Phonon-phonon interactions in Ce0.85Gd0.15O2 − δ nanocrystals studied by Raman spectroscopy. J Raman Spectrosc 40(6):650–655. https://doi.org/10.1002/jrs.2177

Peng C, Wang Y, Jiang K, Bin BQ, Liang HW, Feng J, Meng J (2003) Study on the structure change and oxygen vacation shift for Ce1 − xSmxO2 − δ solid solution. J Alloys Compounds 349(1-2):273–278. https://doi.org/10.1016/S0925-8388(02)00903-9

Li SP, Lu JQ, Fang P, Luo MF (2009) Effect of oxygen vacancies on electrical properties of Ce0.8Sm0.1Nd0.1O2 − δ electrolyte: an in situ Raman spectroscopic study. J Power Sources 193(1):93–98. https://doi.org/10.1016/j.jpowsour.2008.12.022

López JM, Gilbank AL, García T, Solsona B, Agouram S, Torrente-Murciano L (2015) The prevalence of surface oxygen vacancies over the mobility of bulk oxygen in nanostructured ceria for the total toluene oxidation. Appl Catal B Environ 174–175:403–412. https://doi.org/10.1016/j.apcatb.2015.03.017

Stojmenovic M, Boskovic S, Zunic M, Bbic B, Matovic B, Bajuk-Bogdanovic D, Mentus S (2015) Studies on structural, morphological and electrical properties of Ce1 − xErxO2 − δ (x = 0.05–0.20) as solid electrolyte for IT-SOFC. Mater Chem Phys 153:422–431. https://doi.org/10.1016/j.matchemphys.2015.01.036

Anjaneya KC, Nayaka GP, Manjanna J, Govindaraj G, Ganesha KN (2013) Preparation and characterization of Ce1 − xGdxO2 − δ (x = 0.1–0.3) as solid electrolyte for intermediate temperature SOFC. J Alloys Compounds 578:53–59. https://doi.org/10.1016/j.jallcom.2013.05.010

Wu YC, Lin CC (2014) The microstructures and property analysis of aliovalent cations (Sm3+, Mg2+, Ca2+, Sr2+, Ba2+) co-doped ceria-based electrolytes after aging treatment. Int J Hydrog Energy 39(15):7988–8001. https://doi.org/10.1016/j.ijhydene.2014.03.063

Ramesh S, Kumar VP, Kistaiah P, Reddy CV (2010) Preparation, characterization and thermo electrical properties of co-doped Ce0.8 − xSm0.2CaxO2 − δ materials. Solid State Ionics 181(1-2):86–91. https://doi.org/10.1016/j.ssi.2009.11.014

Prashanth Kumar V, Reddy YS (2008) Thermal and electrical properties of rare-earth co-doped ceria ceramics. Mater Chem Phys 112(2):711–718. https://doi.org/10.1016/j.matchemphys.2008.06.030

Tian C, Ji B, Xie J, Bao W, Liu K, Cheng J, Yin Q (2014) Preparation and characterization of Ce0.8La0.2 − xYxO1.9 as electrolyte for solid oxide fuel cells. J Rare Earths 32(12):1162–1169. https://doi.org/10.1016/S1002-0721(14)60198-8

Venkatesh V, Prashanth Kumar V, Sayanna R, Vishnuvardhan Reddy C (2012) Preparation, characterization and thermal expansion of Pr co-dopant in samarium doped ceria. Adv Mater Phys Chem 2(04):5–8. https://doi.org/10.4236/ampc.2012.24B002

Jin C, Yang Z, Zhang H, Yang C, Chen F (2012) La0.6Sr1.4MnO4 layered perovskite anode material for intermediate temperature solid oxide fuel cells. Electrochem Comm 14(1):75–77. https://doi.org/10.1016/j.elecom.2011.11.008

Yaremchenko AA, Brinkmann B, Janssen R, Frade JR (2013) Electrical conductivity, thermal expansion and stability of Y- and Al-substituted SrVO3 as prospective SOFC anode material. Solid State Ionics 247-248:86–93. https://doi.org/10.1016/j.ssi.2013.06.002

Kong X, Sun H, Yi Z, Wang B, Zhang G, Liu G (2017) Manganese-rich SmBaCo2 − x − yMnxMgyO5 + δ (x = 0.5, 1, 11.5 and y = 0.05, 0.1) with stable structure and low thermal expansion coefficient as cathode materials for IT-SOFCs. Ceram Int 43(16):13394–13400. https://doi.org/10.1016/j.ceramint.2017.07.042

Zhang L, Liu M, Huang J, Song Z (2014) Improved thermal expansion and electrochemical performances of Ba0.6Sr0.4Co0.9Nb0.1O3 − δ–Gd0.1Ce0.9O1.95 composite cathodes for IT-SOFCs. Int J Hydrog Energy 39(15):7972–7979. https://doi.org/10.1016/j.ijhydene.2014.03.055

Acknowledgements

One of the authors, Kasarapu Venkataramana, thanks the University Grants Commission (UGC), New Delhi, India, for the financial assistance under the scheme of the UGC-UPE-FAR program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• The microwave sintered Ce0.76Pr0.08Sm0.08Gd0.08O2 − δ (PSG) solid electrolyte has been investigated for the first time.

• Effect of microwave sintering on structural, electrical, and thermal properties has been studied and compared.

• Influence of oxygen vacancy concentration on total ionic conductivity is investigated.

• Microwave-sintered sample PSG-MS30 exhibits the highest total ionic conductivity with moderate thermal expansion coefficient.

• This makes PSG-MS30 as a potential candidate for solid electrolyte in IT-SOFC applications.

Rights and permissions

About this article

Cite this article

Venkataramana, K., Madhuri, C., Shanker, J. et al. Microwave-sintered Pr3+, Sm3+, and Gd3+ triple-doped ceria electrolyte material for IT-SOFC applications. Ionics 24, 3075–3084 (2018). https://doi.org/10.1007/s11581-017-2427-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2427-9