Abstract

Reactive magnetron sputtering was employed to prepare nanocomposite thin films of Ag/Al2O3, on a glass substrate. The films are characterized by the formation of Ag nanoparticles embedded in the Al2O3 matrix, after thermal treatment at 600 °C, which are responsible for the appearance of an outstanding pronounced and narrow localized surface plasmon resonance (LSPR) band. Electron microscopy analysis also revealed the presence of larger Ag fractal aggregates at the film’s surface, responsible for a broad band absorption. Noteworthily, the LSPR band maximum remains at the same position (about 412 nm) for Ag concentrations ranging from 23 to 34 at.%, despite some discernible alterations in both LSPR band intensity and width. An optimized thin film is characterized by full transparency in non-resonant wavelengths due to suppression of Ag aggregates at the film’s surface, while maintaining the LSPR behavior. To better explain the plasmonic behavior of the Ag/Al2O3 films, discrete dipole approximation was used to determine the extinction, scattering, and absorption efficiencies of Ag spheres surrounded by an Al2O3 cap layer. This allowed to ascertain some nanostructural features of the films, pointing to the formation of Ag nanoparticles with average sizes in the order of 40 nm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plasmonics is an innovative discipline of nanophotonics that studies the collective electronic excitation features of noble metal films or nanoparticles (NPs) and has paved the way for revolutionary advancements in various applications, including sensing and spectroscopy. The excitement of the plasmonic field lies in its potential to achieve highly miniaturized and sensitive photonic devices by controlling, manipulating, and amplifying light on the nanometer length scale [1].

Plasmonics allows for the fine manipulation of optical signals at a nanoscale scale by exploiting the interaction of light with coherent electronic excitations occurring at the interface of noble metal nanostructures and dielectric materials [2,3,4]. Gold (Au) and silver (Ag) NPs exhibit localized surface plasmon resonances (LSPR) within the visible spectrum, imparting a distinct color sensation to the nanomaterial. Owing to the optical properties resulting from plasmonic resonance, these noble metal NPs display absorption and scattering bands that can be tuned by the size, shape, distribution, and surrounding dielectric matrix [5,6,7,8,9]. That is why plasmonic NPs hold promise for a wide range of applications such as optoelectronic devices [10], optical switching [11, 12], ultrafast optical communication systems [13], optical waveguides [14], photocatalysis [15,16,17], surface-enhanced Raman spectroscopy (SERS) [18], DNA biosensors [19], and gas sensors [20]. In the latter case, a change of the refractive index of the medium surrounding the NP leads to a redshift in the extinction (LSPR) band towards longer wavelengths, establishing the groundwork for LSPR sensing [21,22,23].

In recent years, considerable efforts have been directed towards designing and fabricating plasmonic nanostructures with optimal LSPR characteristics. Notably, Au, Ag NPs, and Au–Ag bimetallic NPs have emerged as promising candidates, owing to their unique properties and potential for tailoring plasmonic resonances across a broad spectral range [23, 24]. Yet, to develop functional and robust plasmonic devices, the nanoparticles should be dispersed into, or supported by, host and solid materials. In this context, aluminum oxide (Al2O3) emerges as a particularly appealing thin film material in the field of oxide host matrixes, due to its remarkable thermal and chemical stability, dielectric properties, and relatively low refractive index which tunes the LSPR band maximum of noble metal nanoparticles to higher frequencies in the visible range [25].

Several methods can be employed to fabricate Au NPs dispersed in an Al2O3 matrix. These include sol–gel [26], thermal evaporation [27], deposition–precipitation [28], pulsed laser deposition (PLD) [29], and sputtering [30,31,32]. More recently, atomic layer deposition (ALD) coupled with mechanical rolling was reported for fabrication of Ag nanogaps [33].

While various research groups have investigated the ability to achieve tunable absorption bands through alterations in the morphology of Au/Al2O3 nanocomposites [34,35,36], there has been limited exploitation of the optical characteristics and plasmonic properties of Ag/Al2O3 thin films. The interest in the use of Ag NPs is because they reveal higher extinction cross sections than Au NPs (i.e., higher absorption and scattering efficiencies), thereby originating sharp extinction bands associated to higher figures of merit in plasmonic applications [34]. Nevertheless, there are several reports indicating that achieving a specific size for Ag is highly challenging [35]. The control and reproducibility of the reaction are frequently suboptimal, and silver nanoparticles tend to undergo oxidation [36]. Keeping in view the previously reported literature, the assumption is that several significant challenges remain unaddressed. These challenges encompass aspects like nanostructure, composition, and Ag NP growth within Al2O3 thin films, as well as the comprehensive investigation of its optical behavior.

The aim of this research is to delve into the nanoscale morphology and plasmonic response of Ag/Al2O3 thin films prepared through reactive direct current magnetron sputtering and post-deposition thermal annealing. The use of magnetron sputtering to prepare the Ag/Al2O3 thin film was chosen for its well-known reliability, cost-effectiveness, reproducibility, and recognized status as an environmentally friendly deposition process. This work also elucidates the process of determining the size of a silver nanosphere surrounded by an oxide layer (Al2O3) employing the discrete dipole approximation (DDA) model to simulate experimental optical behavior.

Experimental Details

Preparation and Characterization of Ag/Al2O3 Thin Films

Deposition of Ag/Al2O3 Thin Films by Reactive Magnetron Sputtering

In a single step, reactive DC magnetron sputtering was employed to create nanocomposite thin films with Ag “seeds” embedded in an Al2O3 matrix. These Ag/Al2O3 thin films were deposited onto glass substrates (microscope slides), for optical characterization and plasmonic studies. Before thin film deposition, the substrates were activated using plasma treatments to remove surface contaminants and improve thin film adhesion by generating surface defects that promote nucleation sites. This pre-deposition activation was carried out in two steps utilizing a Diener low-pressure plasma machine (Zepto model). Initially, a 5-min treatment in an O2 atmosphere (60 Pa) was performed, followed by a 15-min treatment in an Ar atmosphere (60 Pa), both powered at 50 W. The plasma treatment system, which is supplied with a 13.56-MHz generator (capacitive coupled plasma (CCP) system), achieves a base pressure of 20 Pa.

The deposition chamber is approximately cylindrical in design and has a total volume of 60 L (please see schematics in Fig. S1). The substrate holder, connected to ground (GND), is positioned in the center of the chamber, 7 cm from the target surface. A Hüttinger Elektronik (PFG 2500 DC) DC supply powered the cathode. The deposition process involved sputtering an aluminum target (dimensions, 200 × 100 × 6 mm3; purity, 99.99%) with different number of silver disk or “pellets” (4, 6, and 10, respectively), strategically placed in the preferential erosion zone of Al target. Each silver pellet has a surface area of 16 mm2 and 0.5 mm in thickness. The deposition time was 5 min, yet, to evaluate the effect of deposition time, an Ag/Al2O3 film with a deposition time of 2 minutes was also prepared using the highest number of pellets. The initial system (base) pressure was maintained below 4×10−4 Pa, and the film deposition took place within a reactive atmosphere consisting of argon (Ar) with a partial pressure of 4.0×10−1 Pa and oxygen (O2) with a partial pressure of 8×10−2 Pa. To initiate the plasma, a direct current (DC) current density of 75 A/m2 was applied to the cathode. The target potential remained constant (V= -250 V) after the initial discharge voltage.

Thermal Annealing Treatment to Induce the Formation of Ag NPs

Following the deposition process, the as-deposited films were annealed at 600 °C to promote the growth and coalescence of Ag nanoparticles within the Al2O3 matrix. The objective was to tailor their structural and morphological properties in order to achieve unique plasmonic responses. The annealing treatments were performed in an oven that works at atmospheric pressure. A controlled heating ramp of 5 °C per minute was employed, succeeded by a 5-h isothermal period at the designated temperature (600 °C). After that, the samples were allowed to cool naturally to ambient temperature.

Characterization of the Nanocomposite Films (Chemical, Morphological, and Optical)

The atomic concentration of the as-deposited samples was determined using Rutherford backscattering spectroscopy (RBS). The measurements were taken at 1.4 MeV for 1H and 2 MeV for 4He (normal incidence). The chamber included three detectors: one at a 140° scattering angle and two symmetrically positioned pin-diode detectors at a 165° scattering angle to the beam direction. The RBS data were analyzed with the IBA DataFurnace NDF v10.0c [37, 38].

The morphology and thickness of the Ag/Al2O3 thin films were examined using scanning electron microscopy (SEM) with a Dual Beam SEM/FIB FEI Helios 600i instrument. For this analysis, both in-lens secondary electron and energy-selective backscattered electron detectors were utilized.

The optical transmittance spectra of the films were assessed through spectral measurements utilizing a Shimadzu UV-3101 PC UV–Vis–NIR spectrophotometer.

Modeling the Optical Properties of Ag NPs Embedded in a Cap Layer of Al2O3 Using Discrete Dipole Approximation

The modeling of optical properties in nanoparticles with sizes exceeding 5 nm, where quantum mechanical calculations are unnecessary, predominantly relies on solving the Maxwell equations through various methods, including Mie theory-based codes, the finite-difference time-domain (FDTD) approach, the finite element method (FEM), and the discrete dipole approximation (DDA), among other numerical and approximation methods [39, 40]. The DDA is a computational method for calculating light scattering by a particle of arbitrary shape. Introduced by Purcell and Pennypacker [41], this method involves discretizing the volume occupied by the scattering target through an array of N dipoles. Each dipole is assigned a Clausius–Mossotti polarizability (also known as Lorentz–Lorenz relation). Draine and Flatau later enhanced the approach by refining the model for polarizability [42].

Some of these tools utilize computationally intensive algorithms, which are now accessible to a wider audience thanks to the processing power of modern computers and the availability of parallel computing clusters with open access. NanoHUB, as exemplified by [43], stands out as a user-friendly web-based platform under the administration of Purdue University’s Network for Computational Nanotechnology and funded by the American National Science Foundation. It houses an array of simulation tools designed to facilitate the exploration of light-matter interactions in various contexts. In the specific case of present work, the focus was put on calculating the extinction, scattering, and absorption efficiencies of single nanoparticles (1 layer), core–shell nanoparticles (2 layers), and nanomatryushka nanoparticles (3 layers) using the tool “Extinction, Scattering, and Absorption efficiencies of single and multilayer nanoparticles” that used the Mie formulation. The main simulation parameters are presented in Table 1.

Results and Discussion

Chemical and Morphological Analysis of the Ag/Al2O3 Thin Films

Firstly, the RBS technique allowed to examine the as-deposited samples to determine the atomic concentration of silver (Ag) in the deposited thin films. The increase of the silver pellets placed in the aluminum sputtering target, that corresponded to a total area of 64 mm2, 96 mm2, and 160 mm2, influenced the atomic concentration of the Ag metal in the Al2O3 matrix, by changing it from 23 to 29 at.% and to 34 at.%, respectively.

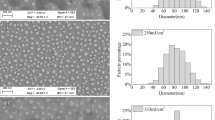

After thermal annealing at 600 °C, the morphology of the Ag/Al2O3 thin films prepared with variable Ag concentration was investigated using SEM, as shown in Fig. 1.

The micrographs taken in the cross-sectional view using in-lens secondary electrons (SE), shown in Fig. 1 (top line), seem to exhibit a dense and compact morphology for the film prepared with the lowest Ag content (CAg = 23 at.%). The increased presence of Ag amount in the film, for 29 at.% and 34 at.%, promotes diffusion processes, allowing Ag clusters and/or nanoparticles to grow, leading to the formation of a morphology with increased porosity and disorder. From the SE micrographs, it was also possible to estimate the thin film thicknesses, from 44 to 87 nm and 170 nm, corresponding to the increasing Ag content. Controlling the deposition rate is essential to achieving the desired properties of the deposited material and ensuring uniformity across the coated surface. Noteworthily, the deposition (growth) rate had a non-linear increase with the content of silver, changing from 9 to 17 nm/min and then to 34 nm/min. The most significant increase in the deposition rate is observed for the film with the highest atomic concentration of Ag, CAg = 34 at.%. This huge deposition rate compared to the other films cannot solely be ascribed to the high sputtering yield of Ag and increasing number of silver pellets; rather, it is also certainly influenced by morphological changes, assuming that the amount of sputtered atoms is increasing linearly. Therefore, the film with higher concentration of Ag exhibits increased porosity and consequently lower density. This alteration in morphology affects the deposition rates or, more precisely, the growth rates, measured for the Ag/Al2O3 samples.

Additionally, through the SEM images acquired using backscattered electrons (BE), it was possible to attain a significantly enhanced atomic weight contrast, particularly relevant to distinguish the Ag grains from host matrix. This analysis allowed to discern the presence of Ag NPs dispersed throughout the cross-sectional profile of annealed films, thereby substantiating the formation of a nanocomposite material with plasmonic behavior.

The distribution of Ag grains in the top-view SEM images is also prominently evident, unveiling the intricate surface topography and the distinctive arrangement of Ag in nanoparticles: (i) inside the matrix (or perhaps partially embedded on it) and also (ii) aggregated in larger clusters at the film’s surface. It is worth noting that the SEM image reveals a heavy agglomeration of Ag grains in the Ag/Al2O3 film with the highest Ag content. The formed Ag NPs and clusters conspicuously manifest as luminous points or coalesced grains in the SEM images, offering insights into their size, morphology, and spatial dispersion, as a result of nucleation and growing mechanisms promoted by the thermal treatment.

Analysis of the Optical Behavior of the Films: Correlation Between LSPR Response and Films’ Morphology

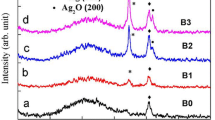

Optical transmission spectroscopy experiments were performed to investigate the LSPR effect manifested by the Ag/Al2O3 thin films, before and after thermal annealing treatment at 600 °C. The formation of Ag NPs throughout the Al2O3 matrix induced the anticipated plasmonic behavior. The optical characteristics were examined using optical transmission measurements, scrutinizing their behavior with respect to the concentration of Ag and annealing temperature. Figure 2 presents the absorbance (A) spectra of as-deposited Ag/Al2O3 thin films with varying Ag concentrations. These spectra were obtained via transmittance (T%) spectra measurements and applying the well-known relation, A (a.u.) = − log (T%/100). Notably, the initial absorbance spectra of the as-deposited thin films did not display any signs of an LSPR band, as the Ag dispersed in the Al2O3 matrix is expected to be in the form of very small nanoparticles, probably below 10 nm size, similarly to what was observed in another work, for the case of Au nanoparticles deposited by the same method [45]. This phenomenon has been discussed in various studies, revealing the lack of (LSPR) band in the as-deposited films. This absence is attributed to the fact that most nanoparticles have sizes below the quantum size limit (~ 10 nm), resulting in exceedingly weak plasmonic absorption, which is challenging to detect [46, 47]. In this reduced size domain, plasmon resonances become more sensitive to the quantum nature of the conduction electrons [47].

However, as illustrated in Fig. 2, the thermal annealing temperature (600 °C) originates a significant change in the optical characteristics of the thin films. A notably pronounced LSPR band can be observed for the different Ag concentrations. Furthermore, Fig. 2 also demonstrates how the increase in Ag concentration affects the absorbance of these thin films, namely, a progressive increase of its overall profile. This feature is certainly related with the morphology of the films that dramatically changed, and this is corroborated by the SEM analysis. While round-shaped nanoparticles were formed across the thin film thickness, perhaps anchored in the interface substrate/film, some Ag atoms have diffused towards the film’s surface to form larger Ag grains with hundreds of nanometers. The diffusion and formation of Ag grains at the film’s surface, sometimes with fractal dimensions, were already reported by the authors in TiO2 [48]. However, these fractal structures do not contribute to a localized and sharp LSPR peak but rather to a broad spectral distribution. Indeed, it was reported that the spectral response exhibits remarkable broad and almost featureless behavior due to the presence of fractal aggregates of Ag in the TiO2 matrix [48]. This is attributed to the diverse array of forms and spatial scales encompassed by these fractal structures. Nevertheless, contrary to what was observed in Ag/TiO2 systems, it seems that the amorphous nature of the Al2O3 matrix does not limit the Ag diffusion towards the surface. Following heat treatment, the Al2O3 matrix persists in an amorphous state, as previously demonstrated [25], demonstrating an apparent inhibition of nanoparticle growth to larger sizes. This effect that occurs for the Ag atoms inside the matrix primarily stems from impeding the coalescence and Ostwald ripening phenomena, which are recognized as mechanisms responsible for the formation of larger-sized nanoparticles [45]. Thus, since the matrix remains dense and there is no grain boundary formation (the preferential paths for Ag diffusion) in Al2O3 films, a fraction of Ag remains within the film, where it can nucleate and form Ag NPs with sizes lower than 50 nm, as observed by chemical contrast in SEM analysis. Noteworthily, regardless of the Ag concentration, a noticeable LSPR peak is consistently observed at 412 nm. Furthermore, the overall increase of the absorbance spectra (including non-resonant wavelengths) is most probably related to the formation of the aforementioned Ag grains at the film’s surface that causes light extinction over the entire spectrum.

It is thus demonstrated that the morphological changes caused by the thermal annealing treatment resulted in a notable change in optical spectra and, in all cases, an appearance of narrow LSPR bands. Simultaneously, the sharp LSPR band is associated to a narrow dispersion of nanoparticle sizes, which is difficult to obtain using other host matrixes, and this outstanding optical behavior is crucial for specific applications such as LSPR sensing, optical filters, or other applications where low band widths are of paramount importance [49, 50].

In an attempt to obtain a sharp LSPR band while avoiding Ag grain formation at the film’s surface, the deposition time of the film deposited with the highest silver concentration was reduced. It was found that a 2-min deposition is the optimal condition to avoid an excess of Ag at the film’s surface and it seems to suppress light extinction over the entire spectrum. As evidenced in Fig. 4, the only and most important feature of the thinner film, deposited during 2 min and annealed at 600 °C, is the appearance of a pronounced extinction band, seen as a transmittance minimum or absorbance maximum. With this deposition time, the Ag concentration in the film was reduced to 28 at.% and the thickness for 22 nm. More details about the morphology of this sample can be found in supplementary material (Fig. S2).

For comparison purposes, Fig. 3 depicts the transmittance and corresponding absorbance spectra of the films prepared at 5- and 2-min deposition time, respectively, and both thermal annealed at 600 °C. It also includes the spectrum of the glass substrate as it has a lower bandgap than Al2O3 and establishes the reference for the optical spectra of thin films deposited on such substrate. The film deposited for 2 min exhibits near-transparency for wavelengths higher than 500 nm, only limited by the glass substrate. This transparency notably drops in a wavelength range peaking at 412 nm, where a distinct and narrow band emerges, corresponding to LSPR behavior. The transmittance minimum, or absorbance maximum, at 412 nm, corresponds to maximum extinction efficiency of the film. This feature holds significant promise for plasmonic applications.

Optical Property Modeling to Predict the Nanostructural Arrangement

Discrete dipole approximation model stands as a pivotal tool in simulating light-matter interactions, offering a robust framework for understanding the optical behavior of particles with complex geometries. Leveraging the correspondence between the parameters “extinction band wavelength” and “particle size,” it becomes possible to predict the size of core and shell nanoparticles using their extinction wavelength information or, conversely, to infer the extinction wavelength based on the nanoparticle size.

In order to determine the effect of an Al2O3 cap layer covering an Ag sphere, different sizes were considered in a first set of simulations, namely, R1 = 10, 20, and 30 nm and R2 varying from 12 to 60 nm, where R1 represents the Ag nanoparticle radius and R2 the total radius (distance from the center of the sphere and the limit of Al2O3 surrounding layer, in a core/shell situation) (see Fig. 4).

Concerning the Ag NP radii utilized in the simulations, it is noteworthy that the scattering efficiency is notably overshadowed by the absorption efficiency coefficient, surpassing it by up to ten orders of magnitude for small particle sizes (10 nm). This behavior has been corroborated in several studies [51, 52]. Consequently, the findings indicate that the extinction efficiency, representing the sum of absorption and scattering efficiencies, closely approximates the absorption efficiency, as exemplified in Fig. S3 of supplementary material. Subsequently, the scattering and absorption efficiencies are almost of the same magnitude when considering Ag NPs with a radius of 20 nm embedded within the oxide matrix (Al2O3) (Fig. S3). Notably, for the highest radius of Ag NPs (R1 = 30 nm), the absorption efficiency diminishes to one-third of the scattering efficiency as the size of the shell increases (Fig. S3). Moreover, the optical characteristics of nanoparticles, including the optical resonance wavelength, extinction efficiency, and the proportionate contribution of scattering to extinction, exhibit significant dependence on nanoparticle size. This dependence facilitates precise tuning of the LSPR band position to specific applications.

As illustrated in Fig. 4, upon reaching a shell radius of 5 nm, the highest intensities of the extinction efficiency coefficient manifest for all the simulated Ag (core) radii. Subsequently, for each Ag core, the intensity of the extinction coefficient decreases as the shell radii increase, and the maximum of extinction exhibits an expectable shift towards higher wavelengths. This tendency is consistent with the results of the Mie theory and open-source experimental data [53]. As is common, when dealing with particles exceeding a diameter of 10 nm, the quantum confinement effect becomes negligible, and the significance of the phase retardation effect becomes apparent [54]. Thus, the LSPR band characteristics are closely dependent of the scattering-to-absorption-ratio resulting from altering the nanoparticle size of noble materials [25].

To infer about the Ag NP size in the films, the DDA was used to calculate scattering and absorption efficiencies that closely match experimental results. According to the first set simulations, R1 = 20 and R2 = 30 nm radii appear to be the closest solution. So, in a second set of simulations, different core/shell sizes were simulated.

Figure 5a illustrates the simulated extinction spectrum, with the core/shell system fixed at R2 = 30 nm, while the Ag core size varies (R1 = 15 nm, 20 nm, and 22 nm). It is noteworthy that as the shell decreases, the extinction band blueshifts to a smaller wavelength while it is becoming more intense. The LSPR band can be identified in an optical transmittance spectrum by a characteristic depression (minimum), or absorbance maximum, and the LSPR resonance frequency corresponds to the extinction maximum [55]. Figure 5b presents the coincidence of both experimental absorbance and simulated extinction efficiency in the LSPR resonance frequency at 412 nm. Considering the initial input parameters set at the start of the simulation and the observed agreement between absorbance peak and simulated extinction spectrum, the estimated average NP radius is about 20 nm (40 nm diameter). To prove this claim, the average diameter of Ag NPs probed by cross-sectional SEM image employing BE, which provides higher atomic weight contrast between Ag and the surrounding matrix, was found to be very close to 40 nm (diameter) (inset of Fig. 5b). Theoretical calculation and experimental data suggest that the Ag NP size predicted for the Ag/Al2O3 films is reasonably appropriate.

a Calculated optical extinction efficiency of different sizes of Ag nanoparticles and constant Al2O3 layer. b Correlation between LSPR band experimentally measured and predicted extinction spectrum of a NP with 20-nm radius and 10-nm cap layer of Al2O3. In a SEM view of the thin film (CAg = 23%), the inset shows the nanoparticle size of Ag NPs

Conclusion

Thin films containing different concentrations of Ag dispersed throughout an Al2O3 matrix were prepared by reactive DC magnetron sputtering followed by a thermal treatment at 600 °C. The progression of Ag nanoparticle growth within the Al2O3 matrix is evident in SEM images taken under varying Ag content and altered deposition times. The thickness of the annealed thin films exhibits an upward trend with a higher Ag concentration in the film. The Ag/Al2O3 films, after annealing at 600 °C, exhibit a pronounced LSPR band within the visible light spectrum that results from strong absorption and scattering efficiencies. This property holds promise for the film’s ability to interact strongly with visible light, suggesting potential applications in areas such as sensing, imaging, and optical devices where precise control and manipulation of light interactions is extremely important. The DDA tool was used to estimate the size of Ag nanoparticles by studying their optical spectra and comparing them to experimental data. The observed plasmonic bands of the fabricated thin films have been supported by proper simulation results for varying core/shell of Ag/Al2O3 films. The model’s conceptual simplicity facilitates a direct physical interpretation of the outcomes, rendering it a useful instrument for researchers aiming to obtain rapid and reliable predictions concerning the plasmonic characteristics of complex nanoparticles.

Data Availability

Data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

References

Stockman MI (2011) Nanoplasmonics: the physics behind the applications. Phys Today 64:39–44. https://doi.org/10.1063/1.3554315

Sanchez VM, Martínez ED, Martinez Ricci ML, Troiani H, Soler-Illia GJAA (2013) Optical properties of au nanoparticles included in mesoporous TiO2 thin films: a dual experimental and modeling study. J Phys Chem C 117:7246–7259. https://doi.org/10.1021/jp3127847

Manoilov EG (2009) Optical and photoluminescent properties of Ag/Al2O3 nanocomposite films obtained by pulsed laser deposition. Semiconductor Physics, Quantum Electronics and Optoelectronics 12:298–301. https://doi.org/10.15407/spqeo12.03.298

Kumar M, Sandeep CSS, Kumar G, Mishra YK, Philip R, Reddy GB (2014) Plasmonic and nonlinear optical absorption properties of Ag:ZrO2 nanocomposite thin films. Plasmonics 9:129–136. https://doi.org/10.1007/s11468-013-9605-z

Lansåker PC, Niklasson GA, Granqvist CG (2012) Thin gold films on SnO2 Temperature-dependent effects on the optical properties. Thin Solid Films 520:3688–3691. https://doi.org/10.1016/j.tsf.2012.01.016

Amendola V, Pilot R, Frasconi M, Maragò OM, Iatì MA (2017) Surface plasmon resonance in gold nanoparticles: a review. J Phys: Condens Matter 29:203002. https://doi.org/10.1088/1361-648X/aa60f3

Gonçalves MR (2014) Plasmonic nanoparticles: fabrication, simulation and experiments. J Phys D Appl Phys 47:213001. https://doi.org/10.1088/0022-3727/47/21/213001

Rycenga M, Cobley CM, Zeng J, Li W, Moran CH, Zhang Q, Qin D, Xia Y (2011) Controlling the synthesis and assembly of silver nanostructures for plasmonic applications. Chem Rev 111:3669–3712. https://doi.org/10.1021/cr100275d

Kelly KL, Coronado E, Zhao LL, Schatz GC (2003) The optical properties of metal nanoparticles: the influence of size, shape, and dielectric environment. J Phys Chem B 107:668–677. https://doi.org/10.1021/jp026731y

Choi H, Ko S-J, Choi Y, Joo P, Kim T, Lee BR, Jung J-W, Choi HJ, Cha M, Jeong J-R, Hwang I-W, Song MH, Kim B-S, Kim JY (2013) Versatile surface plasmon resonance of carbon-dot-supported silver nanoparticles in polymer optoelectronic devices. Nat Photonics 7:732–738. https://doi.org/10.1038/nphoton.2013.181

Hira T, Homma T, Uchiyama T, Kuwamura K, Saiki T (2013) Switching of localized surface plasmon resonance of gold nanoparticles on a GeSbTe film mediated by nanoscale phase change and modification of surface morphology. Appl Phys Lett 103:241101. https://doi.org/10.1063/1.4841975

Inouye H, Tanaka K, Tanahashi I, Hattori T, Nakatsuka H (2000) Ultrafast optical switching in a silver nanoparticle system. Jpn J Appl Phys 39:5132. https://doi.org/10.1143/JJAP.39.5132

Bai S, Li Q, Zhang H, Chen X, Luo S, Gong H, Yang Y, Zhao D, Qiu M (2015) Large third-order nonlinear refractive index coefficient based on gold nanoparticle aggregate films. Appl Phys Lett 107:141111. https://doi.org/10.1063/1.4931759

Ageev LA, Miloslavsky VK, Makovetsky ED, Volosenko VM (2013) Periodic structures formed by ag nanoparticles in AgCl–Ag film waveguides exposed to violet laser light. J Appl Spectrosc 80:389–394. https://doi.org/10.1007/s10812-013-9779-3

Amirjani A, Amlashi NB, Ahmadiani ZS (2023) Plasmon-enhanced photocatalysis based on plasmonic nanoparticles for energy and environmental solutions: a review. ACS Appl Nano Mater 6:9085–9123. https://doi.org/10.1021/acsanm.3c01671

Kumar A, Choudhary P, Kumar A, Camargo PH, Krishnan V (2022) Recent advances in plasmonic photocatalysis based on TiO2 and noble metal nanoparticles for energy conversion, environmental remediation, and organic synthesis. Small 18:2101638. https://doi.org/10.1002/smll.202101638

Shahsavandi F, Amirjani A, Hosseini HR (2022) Plasmon-enhanced photocatalytic activity in the visible range using AgNPs/polydopamine/graphitic carbon nitride nanocomposite. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2022.152728

Stiles PL, Dieringer JA, Shah NC, Van Duyne RP (2008) Surface-enhanced Raman spectroscopy. Annu Rev Anal Chem 1:601–626. https://doi.org/10.1146/annurev.anchem.1.031207.112814

Lednický T, Bonyár A (2020) Large scale fabrication of ordered gold nanoparticle–epoxy surface nanocomposites and their application as label-free plasmonic DNA biosensors. ACS Appl Mater Interfaces 12:4804–4814. https://doi.org/10.1021/acsami.9b20907

Proença M, Rodrigues MS, Borges J, Vaz F (2020) Optimization of Au:CuO nanocomposite thin films for gas sensing with high-resolution localized surface plasmon resonance spectroscopy. Anal Chem 92:4349–4356. https://doi.org/10.1021/acs.analchem.9b05153

Stewart ME, Anderton CR, Thompson LB, Maria J, Gray SK, Rogers JA, Nuzzo RG (2008) Nanostructured plasmonic sensors. Chem Rev 108:494–521. https://doi.org/10.1021/cr068126n

Willets KA, Van Duyne RP (2007) Localized surface plasmon resonance spectroscopy and sensing. Annu Rev Phys Chem 58:267–297. https://doi.org/10.1146/annurev.physchem.58.032806.104607

Khurana K, Jaggi N (2021) Localized surface plasmonic properties of Au and Ag nanoparticles for sensors: a review. Plasmonics 16:981–999. https://doi.org/10.1007/s11468-021-01381-1

Gupta R, Dyer MJ, Weimer WA (2002) Preparation and characterization of surface plasmon resonance tunable gold and silver films. J Appl Phys 92:5264–5271. https://doi.org/10.1063/1.1511275

Meira DI, Domingues RP, Rodrigues MS, Alves E, Barradas NP, Borges J, Vaz F (2020) Thin films of Au-Al2O3 for plasmonic sensing. Appl Surf Sci 500:144035. https://doi.org/10.1016/j.apsusc.2019.144035

Zhao C, Li B, Du J, Chen J, Li Y (2017) Microstructure and optical absorption property of Au nanoparticles and Au, Ag bimetal nanoparticles separately dispersed Al2O3 composite films. J Alloys Compd 691:772–777. https://doi.org/10.1016/j.jallcom.2016.08.332

Ullah I, Tamseel M, Amami M, Javed MR, Javaid K, Mahmood K, Ikram S, Ali A, Amin N, Hussain MS, Ali MY, Arshad MI (2022) Growth and characterization of Ag–Al2O3 composites thin films for thermoelectric power generation applications. Ceram Int 48:3647–3651. https://doi.org/10.1016/j.ceramint.2021.10.145

Zhao G, Gao E, Wan Q, Liu Q, Liang J, Qiao Y, Zhao G, Tian Y (2019) Structure-activity relationships of Au/Al2 O3 catalyst for the selective oxidative esterification of 1,3-propanediol and methanol. ChemistrySelect 4:12479–12490. https://doi.org/10.1002/slct.201903059

Nedyalkov NN, Nakajima Y, Takami A, Koleva M, Karashanova D, Terakawa M (2016) Laser induced morphological and optical properties changes in Au doped aluminum oxide and silicon oxide thin films. Opt Laser Technol 79:179–187. https://doi.org/10.1016/j.optlastec.2015.12.008

Wang J, Lau WM, Li Q (2005) Effects of particle size and spacing on the optical properties of gold nanocrystals in alumina. J Appl Phys 97:114303. https://doi.org/10.1063/1.1868052

Hazra S, Gibaud A, Sella C (2004) Tunable absorption of Au–Al2O3 nanocermet thin films and its morphology. Appl Phys Lett 85:395–397. https://doi.org/10.1063/1.1774250

Jaiswal J, Mourya S, Malik G, Chandra R (2018) Tunable optical properties of plasmonic Au/Al2 O3 nanocomposite thin films analyzed by spectroscopic ellipsometry accounting surface characteristics. J Opt Soc Am A 35:740. https://doi.org/10.1364/JOSAA.35.000740

Cheng T, Zhu Z, Wang X, Zhu L, Li A, Jiang L, Cao Y (2023) Atomic layer deposition assisted fabrication of large-scale metal nanogaps for surface enhanced Raman scattering. Nanotechnology 34:265301. https://doi.org/10.1088/1361-6528/acc8d9

Yin Y, Zhu J, Wang Z, Ma G, Yuan H, Li X (2021) Enhanced plasmonic resonance characteristics of AgNRs–gold film hybrid system. Front Chem 8:553541. https://doi.org/10.3389/fchem.2020.553541

Almatroudi A (2020) Silver nanoparticles: synthesis, characterisation and biomedical applications, Open. Life Sci 15:819–839. https://doi.org/10.1515/biol-2020-0094

Desireddy A, Conn BE, Guo J, Yoon B, Barnett RN, Monahan BM, Kirschbaum K, Griffith WP, Whetten RL, Landman U, Bigioni TP (2013) Ultrastable silver nanoparticles. Nature 501:399–402. https://doi.org/10.1038/nature12523

Barradas NP (2004) Double scattering in grazing angle Rutherford backscattering spectra. Nucl Instrum Methods Phys Res B 225:318–330. https://doi.org/10.1016/j.nimb.2004.04.182

Barradas NP, Jeynes C (2008) Advanced physics and algorithms in the IBA DataFurnace. Nucl Instrum Methods Phys Res B 266:1875–1879. https://doi.org/10.1016/j.nimb.2007.10.044

Wu Y, Nordlander P (2010) Finite-difference time-domain modeling of the optical properties of nanoparticles near dielectric substrates. The Journal of Physical Chemistry C 114:7302–7307. https://doi.org/10.1021/jp908980d

Sun F, Du C, Fu T, Chen Y, Sun L, Zhang R, Shi D (2020) Optimal aspect ratio and excitation spectral region of individual Au Ag1−alloy nanobars for plasmonic sensing. Phys Lett A 384:126785. https://doi.org/10.1016/j.physleta.2020.126785

Purcell EM, Pennypacker CR (1973) Scattering and absorption of light by nonspherical dielectric grains. Astrophys J 186:705. https://doi.org/10.1086/152538

Draine BT, Flatau PJ (1994) Discrete-dipole approximation for scattering calculations. J Opt Soc Am A 11:1491. https://doi.org/10.1364/JOSAA.11.001491

Madhavan K, Zentner L, Farnsworth V, Shivarajapura S, Zentner M, Denny N, Klimeck G (2013) Klimeck, nanoHUB.org: cloud-based services for nanoscale modeling, simulation, and education. Nanotechnol Rev 2:107–117. https://doi.org/10.1515/ntrev-2012-0043

Johnson PB, Christy RW (1972) Optical constants of the noble metals. Phys Rev B 6:4370–4379. https://doi.org/10.1103/PhysRevB.6.4370

Koneti S, Borges J, Roiban L, Rodrigues MS, Martin N, Epicier T, Vaz F, Steyer P (2018) Electron tomography of plasmonic Au nanoparticles dispersed in a TiO2 dielectric matrix. ACS Appl Mater Interfaces 10:42882–42890. https://doi.org/10.1021/acsami.8b16436

Scholl JA, Koh AL, Dionne JA (2012) Quantum plasmon resonances of individual metallic nanoparticles. Nature 483:421–427. https://doi.org/10.1038/nature10904

Bohren CF, Huffman DR (1998) Absorption and scattering of light by small particles. Wiley. https://doi.org/10.1002/9783527618156

Borges J, Rodrigues MS, Lopes C, Costa D, Ferreira A, Pereira RM, Costa MF, Vasilevskiy MI, Vaz F (2016) Ag fractals formed on top of a porous TiO2 thin film. Physica Status Solidi (RRL) – Rapid Research Letters 10:530–534. https://doi.org/10.1002/pssr.201600131

Vaishnav SK, Patel K, Chandraker K, Korram J, Nagwanshi R, Ghosh KK, Satnami ML (2017) Surface plasmon resonance based spectrophotometric determination of medicinally important thiol compounds using unmodified silver nanoparticles. Spectrochim Acta A Mol Biomol Spectrosc 179:155–162. https://doi.org/10.1016/j.saa.2017.02.040

Endo T, Kerman K, Nagatani N, Hiepa HM, Kim D-K, Yonezawa Y, Nakano K, Tamiya E (2006) Multiple label-free detection of antigen−antibody reaction using localized surface plasmon resonance-based core−shell structured nanoparticle layer nanochip. Anal Chem 78:6465–6475. https://doi.org/10.1021/ac0608321

Jain PK, Lee KS, El-Sayed IH, El-Sayed MA (2006) Calculated absorption and scattering properties of gold nanoparticles of different size, shape, and composition: applications in biological imaging and biomedicine. J Phys Chem B 110:7238–7248. https://doi.org/10.1021/jp057170o

van Dijk MA, Tchebotareva AL, Orrit M, Lippitz M, Berciaud S, Lasne D, Cognet L, Lounis B (2006) Absorption and scattering microscopy of single metal nanoparticles. Phys Chem Chem Phys 8:3486. https://doi.org/10.1039/b606090k

Agnihotri S, Mukherji S, Mukherji S (2014) Size-controlled silver nanoparticles synthesized over the range 5–100 nm using the same protocol and their antibacterial efficacy. RSC Adv 4:3974–3983. https://doi.org/10.1039/C3RA44507K

Ghosh SK, Pal T (2007) Interparticle Coupling effect on the surface plasmon resonance of gold nanoparticles: from theory to applications. Chem Rev 107:4797–4862. https://doi.org/10.1021/cr0680282

Rodrigues MS, Borges J, Lopes C, Pereira RMS, Vasilevskiy MI, Vaz F (2021) Gas sensors based on localized surface plasmon resonances: synthesis of oxide films with embedded metal nanoparticles, theory and simulation, and sensitivity enhancement strategies. Appl Sci 11:5388. https://doi.org/10.3390/app11125388

Funding

Open access funding provided by FCT|FCCN (b-on). This research was supported by the Portuguese Foundation for Science and Technology (FCT) in the framework of Strategic Funding UIDB/04650/2020 and also by project CO2Plasmon, with FCT reference EXPL/CTM-REF/0750/2021 (http://doi.org/https://doi.org/10.54499/EXPL/CTM-REF/0750/2021). Diana I. Meira acknowledges FCT for her Ph.D. scholarship with reference SFRH/BD/143262/2019. Joel Borges acknowledges FCT for his research contract funding, reference CEECINST/00156/2018/CP1642/CT0001 (https://doi.org/https://doi.org/10.54499/CEECINST/00156/2018/CP1642/CT0001).

Author information

Authors and Affiliations

Contributions

Conceptualization: J.B. Methodology: H.E.S., J.B. Software: H.E.S., J.B. Validation: M.P., D.I.M., J.B. Formal analysis: H.E.S., J.B. Investigation: H.E.S., D.S.C., M.P., D.I.M. Resources: F.V., J.B. Writing—original draft: H.E.S. Writing—review and editing: F.V., J.B. Visualization: H.E.S. Supervision: F.V., J.B. Project administration: F.V., J.B. Funding acquisition: F.V., J.B.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sekrafi, H.E., Costa, D.S., Proença, M. et al. Experimental and Theoretical Studies on Ag Nanoparticles with Enhanced Plasmonic Response, Formed Within Al2O3 Thin Films Deposited by Magnetron Sputtering. Plasmonics (2024). https://doi.org/10.1007/s11468-024-02227-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11468-024-02227-2