Abstract

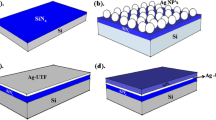

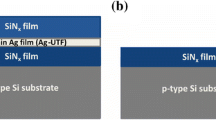

In this paper, focus is on the light trapping surface in crystalline silicon (c-Si) solar cells where thinner c-Si wafers are expected to be used by industry to reduce the cost of cell manufacturing. Currently, 180-μm-thick wafers are being used for fabricating c-Si solar cells where textured surface coated with silicon nitride (SiN x ) anti-reflector enhances the light trapping. However, surface texturing process roughens the surface and increases the probability of more surface recombination as the wafer thickness decreases. This paper presents an analytical analysis for the development of plasmonic anti-reflector as an alternative to traditional texturization for next-generation thin c-Si solar cells. The analysis indicates that loss in current generation due to Si wafer thickness reduction up to 100 μm from currently used 180 μm would not be more than 0.5 mA/cm2 if the light trapping structure is excellent. A 100-μm wafer thickness reduction would increase the front escape of light but not more than 1%. PC1D simulation incorporating experimental reflectance from an equivalent 100-μm thin c-Si wafer-based solar cell structure having proposed dielectric-metal-dielectric (D-M-D)-based anti-reflector indicates 1.2–1.3 mA/cm2 current enhancement when compared with a standard SiN x anti-reflector.

Similar content being viewed by others

References

Green MA (2002) Photovoltaic principles. Phys E Low-dimensional Syst Nanostructures 14:11–17. doi:10.1016/S1386-9477(02)00354-5

Aberle AG (2000) Surface passivation of crystalline silicon solar cells: a review. Prog Photovolt Res Appl 8:473–487. doi:10.1002/1099-159X(200009/10)8:5<473::AID-PIP337>3.0.CO;2-D

Green MA, Zhao J, Wang A, Wenham SR (1999) Very high efficiency silicon solar cells—science and technology. IEEE Trans Electron Devices 46:1940–1947. doi:10.1109/16.791982

Haynos J, Allison J, Arndt R, Meulenberg A (1974) The COMSAT nonreflective silicon solar cell: a second generation improved cell. In: Int. Conf. Photovolt. Power Gener p 18

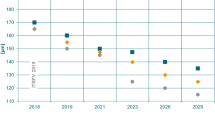

www.itrpv.net/Reports/Downloads/2014/ (2014) International Technology Roadmap for Photovoltaic (ITRPV) 2013 Results

Campbell P, Green MA (1987) Light trapping properties of pyramidally textured surfaces. J Appl Phys 62:243. doi:10.1063/1.339189

Plummer JD, Deal MD, Griffin PB (2000) Silicon VLSI technology: fundamentals, practice and modeling

McIntosh KR, Johnson LP (2009) Recombination at textured silicon surfaces passivated with silicon dioxide. J Appl Phys 105:124520. doi:10.1063/1.3153979

Singh HK, Arunachalam B, Kumbhar S et al (2016) Opto-electrical performance improvement of mono c-Si solar cells using dielectric–metal–dielectric (D-M-D) sandwiched structure-based plasmonic anti-reflector. Plasmonics 11:323–336. doi:10.1007/s11468-015-0049-5

Standard IEC 60904-3 (2008) Measurement principles for terrestrial PV solar devices with reference spectral irradiance data. Int. Electrochem. Comm

PC1D 5.9 PC1D (ver 5.9)- Software for modelling a solar cell

Green MA, Keevers MJ (1995) Optical properties of intrinsic silicon at 300 K. Prog Photovolt Res Appl 3:189–192. doi:10.1002/pip.4670030303

Yablonovitch E (1982) Statistical ray optics. J Opt Soc Am 72:899. doi:10.1364/JOSA.72.000899

Yablonovitch E, Cody GD (1982) Intensity enhancement in textured optical sheets for solar cells. IEEE Trans Electron Devices 29:300–305. doi:10.1109/T-ED.1982.20700

Tiedje T, Yablonovitch E, Cody GD, Brooks BG (1984) Limiting efficiency of silicon solar cells. IEEE Trans Electron Devices 31:711–716. doi:10.1109/T-ED.1984.21594

Brendel R, Queisser HJ (1993) On the thickness dependence of open circuit voltages of p-n junction solar cells. Sol Energy Mater Sol Cells 29:397–401. doi:10.1016/0927-0248(93)90098-N

Petermann JH, Zielke D, Schmidt J et al (2012) 19%-efficient and 43 μm-thick crystalline Si solar cell from layer transfer using porous silicon. Prog Photovolt Res Appl 20:1–5. doi:10.1002/pip.1129

Wang L, Lochtefeld A, Han J et al (2014) Development of a 16.8% efficient 18-um silicon solar cell on steel. IEEE J Photovoltaics 4:1397–1404. doi:10.1109/JPHOTOV.2014.2344769

Sánchez-Aniorte I, Colina M, Perales F, Molpeceres C (2010) Optimization of laser fired contact processes in c-Si solar cells. Phys Procedia 5:285–292. doi:10.1016/j.phpro.2010.08.148

Schneiderlochner E, Preu R, Ludemann R, Glunz SW (2002) Laser-fired rear contacts for crystalline silicon solar cells. Prog Photovolt Res Appl 10:29–34. doi:10.1002/pip.422

Lolgen P, Leguijt C, Eikelboom JA, et al (1993) Aluminium back-surface field doping profiles with surface recombination velocities below 200 cm/s. In: Conf. Rec. Twenty Third IEEE Photovolt. Spec. Conf. - 1993 (Cat. No.93CH3283–9). IEEE, pp 236–242

Narasimha S, Rohatgi A, Weeber AW (1999) An optimized rapid aluminum back surface field technique for silicon solar cells. IEEE Trans Electron Devices 46:1363–1370. doi:10.1109/16.772477

Schmidt J, Merkle A, Brendel R et al (2008) Surface passivation of high-efficiency silicon solar cells by atomic-layer-deposited Al2 O3. Prog Photovolt Res Appl 16:461–466. doi:10.1002/pip.823

Glunz SW, Biro D, Rein S, Warta W (1999) Field-effect passivation of the SiO2 Si interface. J Appl Phys 86:683. doi:10.1063/1.370784

Dekkers HFW, Duerinckx F, Wolf S De, et al (2003) The influence of surface preparation on rear surface passivation of mc-Si by thermally treated direct PECVD silicon nitride. In: Proc. 3rd World Conf. onPhotovoltaic Energy Conversion, 2003. pp 1143–1146

Dullweber T, Gatz S, Hannebauer H et al (2012) Towards 20% efficient large-area screen-printed rear-passivated silicon solar cells. Prog Photovolt Res Appl 20:630–638. doi:10.1002/pip.1198

Schaper M, Schmidt J, Plagwitz H, Brendel R (2005) 20.1%-efficient crystalline silicon solar cell with amorphous silicon rear-surface passivation. Prog Photovolt Res Appl 13:381–386. doi:10.1002/pip.641

Lin Y, Li M, Shen H (2011) Crystalline silicon surface passivation with SiON:H films deposited by medium frequency magnetron sputtering. Phys Procedia 18:56–60. doi:10.1016/j.phpro.2011.06.057

Duttagupta S, Hameiri Z, Grosse T et al (2015) Dielectric charge tailoring in PECVD SiOx/SiNx stacks and application at the rear of Al local back surface field Si wafer solar cells. IEEE J Photovoltaics 5:1014–1019. doi:10.1109/JPHOTOV.2015.2419132

Wang W, Song M, Bae T-S et al (2014) Transparent ultrathin oxygen-doped silver electrodes for flexible organic solar cells. Adv Funct Mater 24:1551–1561. doi:10.1002/adfm.201301359

Johnson PB, Christy RW (1972) Optical constants of the noble metals. Phys Rev B 6:4370–4379. doi:10.1103/PhysRevB.6.4370

Windt DL, Cash WC, Scott M et al (1988) Optical constants for thin films of Ti, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Hf, Ta, W, Re, Ir, Os, Pt, and Au from 24 Å to 1216 Å. Appl Opt 27:246. doi:10.1364/AO.27.000246

Rakić AD, Djurišić AB, Elazar JM, Majewski ML (1998) Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl Opt 37:5271. doi:10.1364/AO.37.005271

McPeak KM, Jayanti SV, Kress SJP et al (2015) Plasmonic films can easily be better: rules and recipes. ACS Photonics 2:326–333. doi:10.1021/ph5004237

Acknowledgements

This work has been carried out at the National Centre for Photovoltaic Research and Education (NCPRE), IIT-Bombay supported by the “Ministry of New Renewable Energy (MNRE), Government of India.” The authors would like to acknowledge Sandeep Kumbhar, Dr. S. Saravanan, Anzar Gani, and other colleagues at NCPRE for their help in fabrication. The authors would also like to acknowledge Dr. Aldrin Antony for discussion and support in deposition of silicon oxynitride (SiON). One of the authors acknowledges MNRE for funding AMANSI project. Authors also acknowledge IIT Bombay Nanofabrication Facility (IITBNF) and the faculty members (Prof. Anil, Prof. B.M. Arora, and Prof. K.L. Narasimhan, Prof. J. Vasi) as well as the staff members for their great team work and support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, H.K., Mondal, S., Arunachalam, B. et al. D-M-D Plasmonic Anti-Reflector for Next-Generation Thin c-Si Solar Cell Applications. Plasmonics 13, 705–714 (2018). https://doi.org/10.1007/s11468-017-0563-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11468-017-0563-8