Abstract

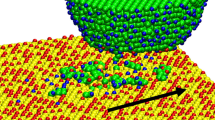

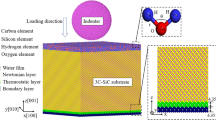

The interfacial wear between silicon and amorphous silica in water environment is critical in numerous applications. However, the understanding regarding the micro dynamic process is still unclear due to the limitations of apparatus. Herein, reactive force field simulations are utilized to study the interfacial process between silicon and amorphous silica in water environment, exploring the removal and damage mechanism caused by pressure, velocity, and humidity. Moreover, the reasons for high removal rate under high pressure and high velocity are elucidated from an atomic perspective. Simulation results show that the substrate is highly passivated under high humidity, and the passivation layer could alleviate the contact between the abrasive and the substrate, thus reducing the damage and wear. In addition to more Si-O-Si bridge bonds formed between the abrasive and the substrate, new removal pathways such as multibridge bonds and chain removal appear under high pressure, which cause higher removal rate and severer damage. At a higher velocity, the abrasive can induce extended tribochemical reactions and form more interfacial Si-O-Si bridge bonds, hence increasing removal rate. These results reveal the internal cause of the discrepancy in damage and removal rate under different conditions from an atomic level.

Similar content being viewed by others

References

Demiri S, Boedo S, Grande W J. Conformality effects on the wear of low-speed, large aspect ratio silicon journal microbearings. Wear, 2010, 268(3–4): 361–372

Bartsch S T, Lovera A, Grogg D, et al. Nanomechanical silicon resonators with intrinsic tunable gain and sub-nW power consumption. ACS Nano, 2012, 6(1): 256–264

Zhang Z, Yan J, Kuriyagawa T. Manufacturing technologies toward extreme precision. International Journal of Extreme Manufacturing, 2019, 1(2): 022001

Fang F, Zhang N, Guo D, et al. Towards atomic and close-to-atomic scale manufacturing. International Journal of Extreme Manufacturing, 2019, 1(1): 012001

Fang F Z. On atomic and close-to-atomic scale manufacturing—Development trend of manufacturing technology. China Mechanical Engineering, 2020, 31(9): 1009–1021 (in Chinese)

Wang J, Fang F, Yan G, et al. Study on diamond cutting of ion implanted tungsten carbide with and without ultrasonic vibration. Nanomanufacturing and Metrology, 2019, 2(3): 177–185

Li J, Liu Y, Dai Y, et al. Achievement of a near-perfect smooth silicon surface. Science China. Technological Sciences, 2013, 56(11): 2847–2853

Asay D B, Kim S H. Effects of adsorbed water layer structure on adhesion force of silicon oxide nanoasperity contact in humid ambient. Journal of Chemical Physics, 2006, 124(17): 174712

Israelachvili J N. Soft and biological structures. In: Israelachvili J N, ed. Intermolecular and Surface Forces. 3rd ed. Salt Lake City: Academic Press, 2011, 535–576

Wang H, Song Z, Liu W, et al. Effect of hydrogen peroxide concentration on surface micro-roughness of silicon wafer after final polishing. Microelectronic Engineering, 2011, 88(6): 1010–1015

Wang Y G, Zhang L C, Biddut A. Chemical effect on the material removal rate in the CMP of silicon wafers. Wear, 2011, 270(3–4): 312–316

Imoto R, Stevens F, Langford S C, et al. Atomic force microscopy studies of chemical-mechanical processes on silicon (100) surfaces. Applied Physics. A, Materials Science & Processing, 2009, 94(1): 35–43

Katsuki F. Single asperity tribochemical wear of silicon by atomic force microscopy. Journal of Materials Research, 2009, 24(1): 173–178

Fang F Z, Wu H, Liu Y C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon. International Journal of Machine Tools and Manufacture, 2005, 45(15): 1681–1686

Fang F Z, Venkatesh V C. Diamond cutting of silicon with nanometric finish. CIRP Annals, 1998, 47(1): 45–49

Wen J, Ma T, Zhang W, et al. Atomistic mechanisms of Si chemical mechanical polishing in aqueous H2O2: ReaxFF reactive molecular dynamics simulations. Computational Materials Science, 2017, 131: 230–238

Chen L, Wen J, Zhang P, et al. Nanomanufacturing of silicon surface with a single atomic layer precision via mechanochemical reactions. Nature Communications, 2018, 9(1): 1542

Hasan R M M, Politano O, Luo X. ReaxFF molecular dynamics simulation study of nanoelectrode lithography oxidation process on silicon (100) surface. Applied Surface Science, 2019, 496: 143679

Murad Hasan R M, Politano O, Luo X. Substrate orientation effects on nanoelectrode lithography: ReaxFF molecular dynamics and experimental study. Journal of Physics D: Applied Physics, 2020, 53(29): 295108

Yu J, Kim S H, Yu B, et al. Role of tribochemistry in nanowear of single-crystalline silicon. ACS Applied Materials and Interfaces, 2012, 4(3): 1585–1593

Chen L, He H, Wang X, et al. Tribology of Si/SiO2 in humid air: Transition from severe chemical wear to wearless behavior at nanoscale. Langmuir, 2015, 31(1): 149–156

Yu J, Chen L, Qian L, et al. Investigation of humidity-dependent nanotribology behaviors of Si (100)/SiO2 pair moving from stick to slip. Applied Surface Science, 2013, 265: 192–200

Wang X, Kim S H, Chen C, et al. Humidity dependence of tribochemical wear of monocrystalline silicon. ACS Applied Materials and Interfaces, 2015, 7(27): 14785–14792

Forsberg M. Effect of process parameters on material removal rate in chemical mechanical polishing of Si (100). Microelectronic Engineering, 2005, 77(3–4): 319–326

Zarudi I, Han B S. Deformation and material removal rate in polishing silicon wafers. Journal of Materials Processing Technology, 2003, 140(1–3): 641–645

Gelinck E R M, Schipper D J. Calculation of Stribeck curves for line contacts. Tribology International, 2000, 33(3–4): 175–181

van Duin A C T, Dasgupta S, Lorant F, et al. ReaxFF: A reactive force field for hydrocarbons. Journal of Physical Chemistry A, 2001, 105(41): 9396–9409

Chenoweth K, van Duin A C T, Goddard W A. ReaxFF reactive force field for molecular dynamics simulations of hydrocarbon oxidation. Journal of Physical Chemistry A, 2008, 112(5): 1040–1053

Senftle T P, Hong S, Islam M M, et al. The ReaxFF reactive force-field: Development, applications and future directions. npj Computational Materials., 2016, 2(1): 15011

Mao Q, Rajabpour S, Kowalik M, et al. Predicting cost-effective carbon fiber precursors: Unraveling the functionalities of oxygen and nitrogen-containing groups during carbonization from ReaxFF simulations. Carbon, 2020, 159: 25–36

Yuan S, Guo X, Mao Q, et al. Effects of pressure and velocity on the interface friction behavior of diamond utilizing ReaxFF simulations. International Journal of Mechanical Sciences, 2021, 191: 106096

Yuan S, Guo X, Huang J, et al. Insight into the mechanism of low friction and wear during the chemical mechanical polishing process of diamond: A reactive molecular dynamics simulation. Tribology International, 2020, 148: 106308

Guo X, Yuan S, Huang J, et al. Effects of pressure and slurry on removal mechanism during the chemical mechanical polishing of quartz glass using ReaxFF MD. Applied Surface Science, 2020, 505:144610

Li X, Wang A, Lee K. Insights on low-friction mechanism of amorphous carbon films from reactive molecular dynamics study. Tribology International, 2019, 131: 567–578

Hahn S H, Liu H, Kim S H, et al. Atomistic understanding of surface wear process of sodium silicate glass in dry versus humid environments. Journal of the American Ceramic Society, 2020, 103(5): 3060–3069

Fogarty J C, Aktulga H M, Grama A Y, et al. A reactive molecular dynamics simulation of the silica-water interface. Journal of Chemical Physics, 2010, 132(17): 174704

Assowe O, Politano O, Vignal V, et al. Reactive molecular dynamics of the initial oxidation stages of Ni(111) in pure water: Effect of an applied electric field. Journal of Physical Chemistry A, 2012, 116(48): 11796–11805

Hoover W G. Canonical dynamics: Equilibrium phase-space distributions. Physical Review A, 1985, 31(3): 1695–1697

Carter S, Handy N C. A variational method for the calculation of rovibronic levels of any orbitally degenerate (Renner-Teller) triatomic molecule. Molecular Physics, 1984, 52(6): 1367–1391

van Gunsteren W F, Berendsen H J C. Algorithms for macro-molecular dynamics and constraint dynamics. Molecular Physics, 1977, 34(5): 1311–1327

Nakano A. Parallel multilevel preconditioned conjugate-gradient approach to variable-charge molecular dynamics. Computer Physics Communications, 1997, 104(1–3): 59–69

Janssens G O A, Baekelandt B G, Toufar H, et al. Comparison of cluster and infinite crystal calculations on zeolites with the electronegativity equalization method (EEM). Journal of Physical Chemistry, 1995, 99(10): 3251–3258

Rappe A K, Goddard W A III. Charge equilibration for molecular dynamics simulations. Journal of Physical Chemistry, 1991, 95(8): 3358–3363

Mortier W J, Ghosh S K, Shankar S. Electronegativity-equalization method for the calculation of atomic charges in molecules. Journal of the American Chemical Society, 1986, 108(15): 4315–4320

Aktulga H M, Fogarty J C, Pandit S A, et al. Parallel reactive molecular dynamics: Numerical methods and algorithmic techniques. Parallel Computing, 2012, 38(4–5): 245–259

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. Journal of Computational Physics, 1995, 117(1): 1–19

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool. Modelling and Simulation in Materials Science and Engineering, 2010, 18(1): 2154–2162

Konicek A R, Grierson D S, Sumant A V, et al. Influence of surface passivation on the friction and wear behavior of ultrananocrystalline diamond and tetrahedral amorphous carbon thin films. Physical Review B, 2012, 85(15): 155448

Wen J, Ma T, Zhang W, et al. Atomic insight into tribochemical wear mechanism of silicon at the Si/SiO2 interface in aqueous environment: Molecular dynamics simulations using ReaxFF reactive force field. Applied Surface Science, 2016, 390: 216–223

Acknowledgements

The authors greatly appreciate the National Major Science and Technology Projects of China (Grant No. 51991372) and the Natural Science Foundation of Liaoning Province, China (Grant No. 2020-MS-120). The authors acknowledge the Beijing PARATERA Tech Co., Ltd., China for providing HPC resources that have contributed to the research results reported within this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, S., Guo, X., Li, P. et al. Atomistic understanding of interfacial processing mechanism of silicon in water environment: A ReaxFF molecular dynamics simulation. Front. Mech. Eng. 16, 570–579 (2021). https://doi.org/10.1007/s11465-021-0642-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-021-0642-6