Abstract

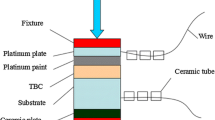

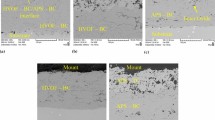

Thermally grown oxide (TGO) may be generated in thermal barrier coatings (TBCs) after high-temperature oxidation. TGO increases the internal stress of the coatings, leading to the spalling of the coatings. Scanning electron microscopy and energy-dispersive spectroscopy were used to investigate the growth characteristics, microstructure, and composition of TGO after high-temperature oxidation for 0, 10, 30, and 50 h, and the results were systematically compared. Acoustic emission (AE) signals and the strain on the coating surface under static load were measured with AE technology and digital image correlation. Results showed that TGO gradually grew and thickened with the increase in oxidation time. The thickened TGO had preferential multi-cracks at the interface of TGO and the bond layer and delayed the strain on the surface of the coating under tensile load. TGO growth resulted in the generation of pores at the interface between the TGO and bond layer. The pores produced by TGO under tensile load delayed the generation of surface cracks and thus prolonged the failure time of TBCs.

Similar content being viewed by others

References

Evans A G, Mumm D R, Hutchinson J W, et al. Mechanisms controlling the durability of thermal barrier coatings. Progress in Materials Science, 2001, 46(5): 505–553

Zhang Q, Li C J, Li Y, et al. Thermal failure of nanostructured thermal barrier coatings with cold-sprayed nanostructured NiCrAlY bond coat. Journal of Thermal Spray Technology, 2008, 17(5–6): 838–845

Padture N P, Gell M, Jordan E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280–284

Toscano J, Naumenko D, Gil A, et al. Parameters affecting TGO growth rate and the lifetime of TBC systems with MCrAlY-bondcoats. Materials and Corrosion, 2008, 59(6): 501–507

Torkashvand K, Poursaeidi E. Effect of temperature and ceramic bonding on BC oxidation behavior in plasma-sprayed thermal barrier coatings. Surface and Coatings Technology, 2018, 349: 177–185

Che C, Wu G Q, Qi H Y, et al. Uneven growth of thermally grown oxide and stress distribution in plasma-sprayed thermal barrier coatings. Surface and Coatings Technology, 2009, 203(20–21): 3088–3091

Liu Y Z, Zheng S J, Zhu Y L, et al. Microstructural evolution at interfaces of thermal barrier coatings during isothermal oxidation. Journal of the European Ceramic Society, 2016, 36(7): 1765–1774

Hu Y, Cai C Y, Wang Y G, et al. YSZ/NiCrAlY interface oxidation of APS thermal barrier coatings. Corrosion Science, 2018, 142: 22–30

Li Y, Li C J, Zhang Q, et al. Effect of chemical compositions and surface morphologies of MCrAlY coating on its isothermal oxidation behavior. Journal of Thermal Spray Technology, 2011, 20(1–2): 121–131

Zhou S F, Xiong Z, Lei J B, et al. Influence of milling time on the microstructure evolution and oxidation behavior of NiCrAlY coatings by laser induction hybrid cladding. Corrosion Science, 2016, 103: 105–116

Tailor S, Modi A, Modi S C. Effect of controlled segmentation on the thermal cycling behavior of plasma sprayed YSZ thick coatings. Ceramics International, 2018, 44(6): 6762–6768

Evans H E. Oxidation failure of TBC systems: An assessment of mechanisms. Surface and Coatings Technology, 2011, 206(7): 1512–1521

Yu Q M, Cen L, Wang Y. Numerical study of residual stress and crack nucleation in thermal barrier coating system with plane model. Ceramics International, 2018, 44(5): 5116–5123

Shen Q, Yang L, Zhou Y C, et al. Effects of growth stress in finite-deformation thermally grown oxide on failure mechanism of thermal barrier coatings. Mechanics of Materials, 2017, 114: 228–242

Yang L, Yang T T, Zhou Y C, et al. Acoustic emission monitoring and damage mode discrimination of APS thermal barrier coatings under high temperature CMAS corrosion. Surface and Coatings Technology, 2016, 304: 272–282

Yang L, Zhong Z C, You J, et al. Acoustic emission evaluation of fracture characteristics in thermal barrier coatings under bending. Surface and Coatings Technology, 2013, 232(10): 710–718

Wang L, Ni J X, Shao F, et al. Failure behavior of plasma-sprayed yttria-stabilized zirconia thermal barrier coatings under three-point bending test via acoustic emission technique. Journal of Thermal Spray Technology, 2017, 26(1–2): 116–131

Yao W B, Dai C Y, Mao W G, et al. Acoustic emission analysis on tensile failure of air plasma-sprayed thermal barrier coatings. Surface and Coatings Technology, 2012, 206(18): 3803–3807

Shen Q, Yang L, Zhou Y C, et al. Models for predicting TGO growth to rough interface in TBCs. Surface and Coatings Technology, 2017, 325: 219–228

Gürgen S, Diltemiz S F, Kushan M C. Oxidation and thermal shock behavior of thermal barrier coated 18/10CrNi alloy with coating modifications. Journal of Mechanical Science and Technology, 2017, 31(1): 149–155

Baskaran T, Arya S B. Role of thermally grown oxide and oxidation resistance of samarium strontium aluminate based air plasma sprayed ceramic thermal barrier coatings. Surface and Coatings Technology, 2017, 326: 299–309

Ma K K, Tang X C, Schoenung J M. Mechanistic investigation into the role of aluminum diffusion in the oxidation behavior of cryomilled NiCrAlY bond coat. Journal of Wuhan University of Technology-Materials Science Edition, 2016, 31(1): 35–43

Liu X J, Wang T, Li C C, et al. Microstructural evolution and growth kinetics of thermally grown oxides in plasma sprayed thermal barrier coatings. Progress in Natural Science-Materials International, 2016, 26(1): 103–111

Keyvani A, Bahamirian M. Oxidation resistance of Al2O3-nanostructured/CSZ composite compared to conventional CSZ and YSZ thermal barrier coatings. Materials Research Express, 2016, 3(10): 105047

Liang G Y, Zhu C, Wu X Y, et al. The formation model of Ni-Cr oxides on NiCoCrAlY-sprayed coating. Applied Surface Science, 2011, 257(15): 6468–6473

Suo Z, Kubair D V, Evans A G, et al. Stresses induced in alloys by selective oxidation. Acta Materialia, 2003, 51(4): 959–974

Pal S, Kubair D V. Finite element simulations of microvoid growth due to selective oxidation in binary alloys. Modelling and Simulation in Materials Science and Engineering, 2006, 14(7): 1211–1223

Yu Q M, Cen L. Residual stress distribution along interfaces in thermal barrier coating system under thermal cycles. Ceramics International, 2017, 43(3): 3089–3100

Wei S, Wang G, Yu J, et al. Competitive failure analysis on tensile fracture of laser-deposited material for martensitic stainless steel. Materials & Design, 2017, 118: 1–10

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51775553 and 51535011). Their assistance is acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, L., Di, Y., Liu, Y. et al. Effect of TGO on the tensile failure behavior of thermal barrier coatings. Front. Mech. Eng. 14, 452–460 (2019). https://doi.org/10.1007/s11465-019-0541-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-019-0541-2