Abstract

This paper proposes a new eddy current method, named equivalent unit method (EUM), for the thickness measurement of the top copper film of multilayer interconnects in the chemical mechanical polishing (CMP) process, which is an important step in the integrated circuit (IC) manufacturing. The influence of the underneath circuit layers on the eddy current is modeled and treated as an equivalent film thickness. By subtracting this equivalent film component, the accuracy of the thickness measurement of the top copper layer with an eddy current sensor is improved and the absolute error is 3 nm for sampler measurement.

Similar content being viewed by others

References

Tanwar K, Canaperi D, Lofaro M, et al. BEOL Cu CMP process evaluation for advanced technology nodes. Journal of the Electrochemical Society, 2013, 160(12): D3247–D3254

Qu Z, Zhao Q, Meng Y, et al. In-situ measurement of Cu film thickness during the CMP process by using eddy current method alone. Microelectronic Engineering, 2013, 108: 66–70

Qu Z, Zhao Q, Meng Y. Improvement of sensitivity of eddy current sensors for nano-scale thickness measurement of Cu films. NDT & E International, 2014, 61: 53–57

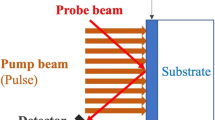

Qu Z, Zhao Q, Meng Y. Characterization of submicronmeter thickness of copper film on silicon by using pulsed eddy currents method. In: Proceedings of 2011 International Conference on Electric Information and Control Engineering (ICEICE 2011). Wuhan, 2011, 1220–1223

Qu Z, Zhao Q, Yu Q, et al. Cu layer thickness monitoring in CMP process by using eddy current sensor. In: Proceedings of International Conference on Planarization/CMP Technology (ICPT 2012). Grenoble: VDE, 2012, 1–5

Li H, Qu Z, Zhao Q, et al. A reliable control system for measurement on film thickness in copper chemical mechanical planarization system. Review of Science Instrument, 2013, 84(12): 125101

Qu Z, Zhao Q, Meng Y. Online measurement of water concentrations of oil-water mixture in the flow of pipeline by using eddy current method. Measurement Science and Technology, 2013, 24(12): 125304

Yin W L, Dickinson S J, Peyton A J. Imaging the continuous conductivity profile within layered metal structures using inductance spectroscopy. IEEE Sensors Journal, 2005, 2(5): 161–166

Yin W L, Peyton A J. Thickness measurement of non-magnetic plates using multi-frequency eddy current sensors. NDT & E International, 2007, 40(1): 43–48

Yin W L, Peyton A J, Zysko G, et al. Simultaneous noncontact measurement of water-level and conductivity. IEEE Transactions on Instrumentation and Measurement, 2008, 57(11): 2665–2669

MIT Open Course Ware. http://ocw.mit.edu/courses/electrical-engineering-and-computer-science/6-012-microelectronic-devicesand-circuits-spring-2009/index.htm

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qu, Z., Meng, Y. & Zhao, Q. Eddy current measurement of the thickness of top Cu film of the multilayer interconnects in the integrated circuit (IC) manufacturing process. Front. Mech. Eng. 10, 1–6 (2015). https://doi.org/10.1007/s11465-015-0325-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-015-0325-2