Abstract

To ascertain the unexpected departure of traditional statistical seismic laws with largest labquakes on model granular materials, we enlarge the behaviour of stick-slip motions in triaxial compression under drained and quasi-static shearing conditions. We estimate the effectiveness of these extended seismic laws (Gutenberg-Richter, inter-event times, and productivity) against more widespread laboratory conditions approaching real-world cases. Regardless of the saturation (dry, water-wet, and water-saturated) of the granular assembly, the initial density (very loose to medium dense), and the effective initial confining pressure up to 500 kPa, large and repeated spontaneous stick-slip frictional failures under uncontrolled triggering stress suggest the universality of these extended empirical seismic relations on laboratory shear experiments with model granular materials. These laboratory extended seismic laws can help to understand qualitatively natural earthquakes of potentially largest magnitude.

Similar content being viewed by others

References

Alshibli KA, Roussel LE (2006) Experimental investigation of stick-slip behaviour in granular materials. Int J Num Ana Meth Geom 30(14):1391–1407

Andreotti B, Forterre Y, Pouliquen O (2013) Granular media: between fluid and solid. Cambridge University Press, Cambridge

Anthony JL, Marone C (2005) Influence of particle characteristics on granular friction. J Geophys Res 110:B08409

Bak P, Christensen K, Danon L, Scanlon T (2002) Unified scaling law for earthquakes. Phys Rev Lett 88:178501

Barés J, Dubois A, Hattali L, Dalmas D, Bonamy D (2018) Aftershock sequences and seismic-like organization of acoustic events produced by a single propagating crack. Nat Comm 9:1253

Baró J, Corral A, Illa X, Planes A, Salje E, Schranz W, Soto-Parra D, Vives E (2013) Statistical similarity between the compression of a porous material and earthquakes. Phys Rev Lett 110:088702

Berman AD, Ducker WA, Israelachvili JN (1996) Experimental and theoretical investigations of stick-slip friction mechanisms. In: Tosati E, Persson B (eds) Physics of sliding friction. Kluwer Academic Publishers, Armsterdam, pp 51–67

Bjerrum L, Krimgstad S, Kummeneje O (1961) The shear strength of a fine sand. In: Proc. 5th Int. Conf. Soil. Mech. Found. Engrg., volume 1, p 29–37

Brace WF, Byerlee JD (1966) Stick-slip as a mechanism for earthquakes. Science 153(6357):990–992

Çabalar AF, Clayton CRI (2010) Some observations of the effects of pore fluids on the triaxial behaviour of a sand. Granular Matt 12(1):87–95

Corral A (2004) Long-term clustering, scaling, and universality in the temporal occurrence of earthquakes. Phys Rev Lett 92:108501

Costa LS, Lenzi EK, Mendes RS, Ribeiro HV (2016) Extensive characterization of seismic laws in acoustic emissions of crumpled plastic sheets. Europhys Lett 114:59002

Cui D, Wu W, Xiang W, Doanh T, Chen Q, Wang S, Liu Q, Wang J (2017) Stick-slip behaviours of dry glass beads in triaxial compression. Granular Matt 19(1):1

Dahmen KA, Ben-Zion Y, Uhl JT (2009) Micromechanical model for deformation in solids with universal predictions for stress-strain curves and slip avalanches. Phys Rev Lett 102:175501

Denisov DV, Lörincz KA, Wright WL, Hufnagel TC, Nawano A, Gu X, Uhl JT, Dahmen KA, Schall P (2017) Universal slip dynamics in metallic glasses and granular matter - linking frictional weakening with inertial effects. Sci Rep 7:43376

Denisov DV, Lörincz Uhl JT, Dahmen KA, Schall P (2016) Universality of slip avalanches in flowing granular matter. Nat Comm 7:10641

Dieterich JH (1979) Modeling of rock friction 1. Experimental results and constitutive equations. J Geophys Res 84(B5):2161–2168

Doanh T, Abdelmoula N, Nguyên TTT, Hans S, Boutin C, Le Bot A (2016) Unexpected liquefaction under isotropic consolidation of idealized granular materials. Granular Matt 18(3):67

Doanh T, Dubujet Ph, Touron T (2010) Exploring the undrained induced anisotropy of Hostun RF loose sand. Acta Geotechnica 5(4):239–256

Doanh T, Hoang MT, Roux J-N, Dequeker C (2013) Stick-slip behaviour of model granular materials in drained triaxial compression. Granular Matt 15(1):1–23

Doanh T, Ibraim E (2000) Minimum undrained strength of Hostun RF. Géotechnique 50(4):377–392

Doanh T, Ibraim E, Matiotti R (1997) Undrained instability of very loose Hostun sand in triaxial compression and extension. Part 1: experimental observations. Mech Cohesive-Frict Mater 2(1):47–70

Doanh T, Le Bot A, Abdelmoula N, Hans S, Boutin C (2014) Liquefaction of immersed granular media under isotropic compression. Europhys Lett 108(2):24004

Doanh T, Nguyên TTT Unexpected departure from seismic laws with largest labquakes on model granular materials. Unpublished, 0(0):0–0

Dorostkar O, Guyer RA, Johnson PA, Marone C, Carmeliet J (2017) On the role of fluids in stick-slip dynamics of saturated granular fault gouge using a coupled computational fluid dynamics-discrete element approach. J Geophys Res Solid Earth 122(5):3689–3700

Gasparini P, Manfredi G, Zschau J (2007) Earthquake early warning systems. Springer, Berlin

Glette-Iversen I, Aven T (2021) On the meaning of and relationship between dragon-kings, black swans and related concepts. Reliab Eng & Sys Safety 211:1–13

Goebel THW, Rosson Z, Brodsky EE, Walter JI (2019) Aftershock deficiency of induced earthquake sequences during rapid mitigation efforts in oklahoma. Earth Planet Sci Lett 522(6240):135–143

Goren L, Aharonov E, Sparks D, Toussaint R (2011) The mechanical coupling of fluid-filled granular material under shear. Pure Appl Geophys 168(12):2289–2323

Gutenberg B, Richter CF (1956) Magnitude and energy of earthquakes. Ann Geophys 9:1–15

Hareb H, Doanh T (2012) Probing into the strain induced anisotropy of Hostun RF loose sand. Granular Matt 14(5):589–605

Helmstetter A (2003) Is earthquake triggering driven by small earthquakes? Phys Rev Lett 91:058501

Kabla A, Debrégeas G (2004) Contact dynamics in a gently vibrated granular pile. Phys Rev Lett 92(3):035501

Kumar P, Korkolis E, Benzi R, Denisov D, Niemeijer A, Schall P, Toschi F, Trampert J (2020) On interevent time distributions of avalanche dynamics. Sci Rep 10:626

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23

Lade PV (2016) Triaxial testing of soils. Wiley, Hoboken

Lade PV, Duncan JM (1973) Cubical triaxial tests on cohesionless soil. J Soil Mech Found ASCE 99(10):793–812

Lherminier S, Planet R, Levy dit Vehel V, Simon G, Vanel L, Måløy K J, Ramos O, (2019) Continuously sheared granular matter reproduces in detail seismicity laws. Phys Rev Lett 122:218501

Maaß R, Wraith M, Uhl JT, Greer JR, Dahmen KA (2015) Slip statistics of dislocation avalanches under different loading modes. Phys Rev E 91(4):042403

Mair K, Frye KM, Marone C (2002) Influence of grain characteristics on the friction of granular shear zones. J Geophys Res 107(B10):2219

Marone C (1998) Laboratory-derived friction laws and their application to seismic faulting. Annu Rev Earth Planet Sci 26:643–696

Miller SA (2020) Aftershocks are fluid-driven and decay rates controlled by permeability dynamics. Nat Comm 11:5787

Mitarai N, Nori F (2006) Wet granular materials. Adv Phys 55(1–2):1–45

Murphy KA, Dahmen KA, Jaeger HM (2019) Transforming mesoscale granular plasticity through particle shape. Phys Rev X 9:011014

Nasuno S, Kudrolli A, Bak A, Gollub JP (1998) Time-resolved studies of stick-slip friction in sheared granular layers. Phys Rev E 58(2):2161–2171

Nguyên TTT, Doanh T, Le Bot A, Dalmas D (2019) On the role of pore pressure in dynamic instabilities of saturated model granular materials. Granular Matt 21(3):61

Nguyên TTT, Doanh T, Le Bot A, Dalmas D (2021) High-temporal-resolution quasideterministic dynamics of granular stick-slip. Sci Rep 11:2902

Nicot F, Xiong H, Wautier A, Lerbet J, Darve F (2017) Force chain collapse as grain column buckling in granular materials. Granular Matt 19(2):18

Ribeiro HV, Costa LS, Alves LGA, Santoro PA, Picolli S, Lenzi EK, Mendes RS (2015) Analogies between the cracking noise of ethanol-dampened charcoal and earthquakes. Phys Rev Lett 115:025503

Ruina A (1983) Slip instability and state variable friction law. J Geophys Res 88(B12):10359–10370

Scholz C (1968) The frequency-magnitude relation of microfracturing in rock and its relation to earthquakes. BSSA 58:399–415

Scholz C (2002) The mechanics of earthquakes and faulting, 2nd edn. Cambridge University Press, Cambridge

Sornette D, Ouillon G (2012) Dragon-kings: mechanisms, statistical methods and empirical evidence. Eur Phys J Special Topics 205:1–26

Terzaghi K, Peck RP, Mesri G (1996) Soil mechanics in engineering practice, 3rd edn. Wiley, Hobroken

Tordesillas A, Zhang J, Behringer R (2009) Buckling force chains in dense granular assemblies: physical and numerical experiments. Geomech. Geoeng: Int J 4(1):3–16

Verruijt A (2010) An introduction to soil dynamics. Springer, Berlin

Wetzler N, Lay T, Brodsky EE, Kanamori H (2018) Systematic deficiency of aftershocks in areas of high coseismic slip for large subduction zone earthquakes. Sci Adv 4:eaa03225

Wu K, Abriak N, Becquart F, Pizette P, Rémond S, Liu S (2017) Shear mechanical behavior of model materials samples by experimental triaxial tests: case study of 4 mm diameter glass beads. Granular Matt 19(4):65

Wu K, Pizette P, Becquart F, Rémond S, Abriak N, Xu W, Liu S (2017) Experimental and numerical study of cylindrical triaxial test on mono-sized glass beads under quasi-static loading condition. Adv Powd Technol 28(1):155–166

Wu K, Rémond S, Abriak N, Pizette P, Becquart F, Liu S (2017) Study of the shear behavior of binary granular materials by DEM simulations and experimental triaxial tests. Adv Powd Technol 28(9):2198–2210

Yang J, Wei LM (2012) Collapse of loose sand with the addition of fines: the role of particle shape. Géotechnique 62(12):1111–1125

Zhang L, Nguyen NGH, Lambert S, Nicot F, Prunier F, Djeran-Maigre I (2017) The role of force chains in granular materials: from statics to dynamics. Eur J Environ Civil Eng 21(7–8):874–895

Acknowledgements

We thank sincerely our colleagues D. Dalmas and A. Le Bot for their feedback.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Experimental details

Particle size distribution, frequency histogram and SEM (scanning electron microscopy) image of SLG 6-8 glass beads of 0.7 mm of diameter [20]

We use industrial soda-lime glass beads “Sil-glass” commercialized by CVP, Linselles, FranceFootnote 1. For completeness, in Fig. 7, we recall successively the grading curve using a particle size analyser by laser diffraction, the frequency histogram and the SEM (scanning electron microscopy) image of SLG 6-8 spherical glass beads of 0.7 mm of diameter [20]. To have a nearly monodisperse population, the glass beads are first sieved to eliminate a small amount of beads smaller than 0.3 mm of diameter. These beads have a static friction coefficient of 0.24, a Mohs hardness of 5 to 6, and a chemical composition in Table 3, dominated by SiO\(_2\), Na\(_2\)O, and CaO, according to CVP.

The quasi-perfect spherical glass beads are often referred to as model or idealized granular materials for the following reasons: (1) as a replacement of popular laboratory Hostun and Toyoura sands with similar mean diameter [31], (2) as artificial monodisperse granular materials with no equivalent in natural sands, (3) as proxies for gouge materials in fault zones in rock mechanics and geoscience fields [3, 40, 41], and (4) as native hypothetical materials for DEM numerical simulations [16, 25, 29]. That is why we combine model or idealized granular materials with triaxial equipment, which is in one of the most versatile shearing machine in soil mechanics. Then we explore the isotropic and triaxial shearing experiments and discover some unknown phenomena (isotropic collapse, isotropic liquefaction, extremely large compression stick-slip, and even compression liquefaction during the slip phase).

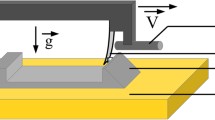

Furthermore, the modification of the triaxial apparatus, the sample preparation, the initial void ratio determination, and the verification of the anti-frictional system are given in previous works on fully saturated granular materials [19, 21, 22, 31].

The experimental details for this study can be found in our previous works [24, 47], excepting the following fabrication procedures for dry and wet states:

For saturated and wet samples, we used a modified moist tamping and under compaction method [8, 35], mixed with 2% of distilled water by weight, then placed in the triaxial mould in five layers, and compacted up to prescribed thickness inside an open ended cylindrical latex membrane of 0.3 mm of thickness. This fabrication procedure gives an initially very loose density for wet sample, with negative relative density. With only 2% of distilled water by weight, we obtained presumably the pendular regime with discontinuous liquid bridges formed between neighbouring grains [43]. Applying further the additional saturation \(CO_{2}\) method and high back pressure (\(U_o\) = 200 kPa) will saturate (i.e. grains fully immerged in de-aired water) this wet sample [37].

Temporal evolution of the first stick-slip event, SS\(_{1}\) at 400 kPa of confining pressure, on medium dense and dry granular assembly within the first 10 seconds: a vertical top cap acceleration, b deviatoric stress, c excess pore pressure, d incremental axial strain, e lateral vibration, and f radial sound pressure

Temporal evolution of the first stick-slip event, SS\(_{1}\) at 400 kPa of confining pressure, on very loose and wet granular assembly within the first 10 seconds: a vertical top cap acceleration, b deviatoric stress, c excess pore pressure, d incremental axial strain, e lateral vibration, and f radial sound pressure

For dry samples, we used a dry deposition method (i.e. gentle placement by spoon with zero free fall height) giving an initially medium dense state [36], even without any initial compaction. It is currently not possible to create an initially very loose density for dry sample. Dry and wet samples have no back pressure (\(U_o\) = 0 kPa).

To fully measure the small outburst of pore air pressure during the stick-slip instability of dry and wet samples, especially the initial oscillating period and its stabilized value, we simply close the top and bottom drainage valves, preventing the pore air pressure dissipation from happening in Fig. 8 and Fig. 9, consequently reducing slightly the effective confining stress of a few kPa, without compromising the stress–strain behaviours.

The complementary measurements of acoustic emission has one small piezoelectric waterproof accelerometer with resolution of 350 \(\mu \)g within 10 kHz (PCB 607A11) inside the triaxial chamber, on the sample top cap, one non-contact portable laser vibrometer, Ometron OH-100-D and one free-field prepolarized microphone, BSWA MPA408 with ICCP preamplifier MA408. The non-submersible vibrometer and microphone are located outside the triaxial chamber.

From the granular literature and from our previous work [20], axial strain rate \({\dot{\varepsilon }}_a\) has important effects of the stick-slip phenomenon. Our multistage drained compression tests in this work suggested a velocity-weakening behaviour of bead assemblies and even confirmed the existence of a critical strain rate \({\dot{\varepsilon }}_a^{crit}\) for a complete disappearance of stick-slip behaviour. Since our paper is focused on the dynamic behaviour, we preferred to fully explore this domain with only one constant axial strain rate of 0.0048%/s for a quasi-static regime.

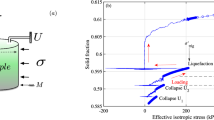

Effects of very large stick-slips on the probability density distribution of acoustic energies (lateral vibration (top) and radial sound pressure (bottom)) of water-saturated, dry, and wet granular assembly. Regardless of the saturation state, the initial solid fraction, and the initial confining pressure, we obtain reasonably a departure beyond a crossover energy

1.2 Stick-slip dynamics

Figures 8 and 9 give, from top to bottom, the complementary typical temporal evolution of vertical top cap acceleration G, deviatoric stress q, excess pore fluid pressure \(\Delta U\) from constant back-pressure \(U_{0}\), incremental axial strain, lateral vibration, and radial sound pressure for the first stick-slip SS\(_1\) of dry and wet states at 400 kPa of confining stress.

In these figures, we still observe systematically and consistently a positive time delay of pore fluid pressure outburst behind the deviatoric stress drop and the vertical top cap acceleration, regardless of the saturation states and the confining stress.

Note the oddly negative incremental axial strain in extension for the dry case in Fig. 8. We already notice that this negative incremental axial strain in extension does happen for almost half of our large stick-slips for the saturated case [47], prior to the expected subsequent axial strain in compression.

Since this axial extension strain happens irrespective of the saturation condition, we are inclined to believe that it cannot be an experimental artefact. The recent preliminary analyses of our newest experimental series equipped with two external Phantom high-speed cameras and PIV (particle image velocimetry) software seem to capture this unexpected axial extension strain behaviour. The results will be published elsewhere. However, we still do not know how to explain scientifically this highly counter-intuitive observation for a compression experiment sheared with constant positive axial strain rate.

We use the same automatic procedures in [24] to identify each stick-slip motion and estimate its parameters (the sudden dynamic stress drop, the changes in vertical top cap acceleration, lateral vibration and radial sound pressure, the vertical acceleration peak, the pore fluid pressure outburst, the dynamic axial and volumetric slip, the duration of each stick-slip, and the inter-event time, as well as the acoustic energy).

Table 2 shows the effective actual resolution of various static and dynamic measurements, taking into account native transducer resolution, instrumentation amplifier, transfer function, transducer calibration, different electrical cables, data acquisition systems, computers, and software. As expected, the practical effective resolution is almost ten times the theoretical native transducer resolution.

Table 4 gives the number of stick-slips identified from vertical acceleration as function of confining stress, from 50 up to 500 kPa, and three tested saturation conditions (water-saturated, water-wet, and completely dry). Note the particular case of wet state, generating a high number of very small stick-slips, on average more than three times that of the other two cases. These stick-slips are used to estimate the power exponent \(\beta _1\) of Gutenberg-Richter relation \(P(E) \sim E^{-\beta }\) for small stick-slip events between \(E_{min}\) and \(E_c\) and \(\beta _2\) for very large events beyond \(E_c\) in Table 5.

Effects of saturation on the probability density distribution of inter-event time \(\Delta t_{E \geqslant E_0}\) for stick-slips in triaxial compression under 500 kPa of confining pressure for (top) events greater than \(E_0\) = 10\(^{-4}\) of acceleration energy (bottom) \(E_0\) = 10\(^{-5}\) (arbitrary unit)

Figure 10 shows the probability density distribution of acoustic energies from the lateral vibration and radial sound pressure, spanning over nearly seven order of energy magnitude. It also supports qualitatively the departure of Gutenberg-Richter relation into double power law for large stick-slips beyond a crossover energy, regardless of confining pressure, initial density, and saturation conditions; unfortunately with different power exponents. Remind that the non-contact portable laser vibrometer and the free-field prepolarized microphone are located outside the triaxial chamber, while the vertical acceleration is attached directly on the sample top cap. Note also the successive presence of the latex membrane, water and the triaxial cell between the granular mixture and these external sensors. The difficulties to correctly interpret these indirect measurements might explain partly the discrepancies in the power exponent of the lateral vibration and the radial sound pressure. Table 6 gives separately the double power exponent \(\beta _1\) and \(\beta _2\) from Gutenberg-Richter relation, separated by an energy \(E_c\), in three methods of acoustic measurements for a series of 50 to 500 kPa of normal stress in Fig. 10. Note the systematic presence of a sharp kink below \(E_{min}\) in the distribution of lateral vibration. The relatively low correlation coefficient of the radial sound pressure can be partly explained by the unusual distribution at 50 kPa of normal stress.

Although with different \(E_{min}\) and \(E_c\), different direct (vertical acceleration on sample top cap) and indirect (contactless lateral vibration) acoustic measurements give very similar double power exponent \(\beta _1\), 1.54 vs 1.85, and \(\beta _2\), 1.04 vs 1.19, with high correlation. However, higher values of \(\beta _1\) and \(\beta _2\) are obtained for indirect radial sound pressure. These values strengthen the modification of usual seismic relations by the presence of very laboratory large stick-slip events. Our rare, extreme stick-slip events on saturated case could be considered as experimental evidence for Dragon-king events [27, 53], at least in laboratory frictional experiments.

Figure 11 gives similar probability density distribution of inter-event times \(\Delta t_{E \geqslant E_0}\), obtained with vertical acceleration, for two threshold energies \(E_0\) = 10\(^{-4}\) and 10\(^{-5}\), comparing to the reference energy of 10\(^{-6}\) (solid circles) for compression stick-slips under constant confining pressure of 500 kPa. This figure supports globally the character of power law on the probability density distribution of normalized inter-event times and also invalidates the usual gamma distribution for natural earthquakes. Similar results (not shown) are obtained for different normal stresses.

Temporal evolution of stick-slip events within a segment of 500 to 1000 seconds on the stress plateau at 400 kPa of confining pressure. (Left) deviatoric stress, (right) vertical top cap acceleration at full vertical scale, up to 100 g. The close-up in insets around one particular stick-slip with very small acceleration range, down to only 0.2 g, shows a long quiescence period with virtually no aftershocks with background noise of 0.005 g or water-saturated sample (top a, b), and shorter quiescence period for two other saturation conditions: dry (middle c, d) and wet (bottom e, f)

Figure 12 shows the mean number of foreshocks as a productivity law of the mechanical acceleration energy of stick-slips under constant confining pressure from 50 up to 500 kPa for all events of saturated, dry, and wet granular assembly. The usual productivity power law is valid only up to a same crossover energy \(E_c \approx \) 10\(^{-1}\) (vertical dashed line). Below \(E_c\), the slope of the productivity evolves from 0.51 at 500 kPa down to 0.65 at 50 kPa; and points towards 1.0 beyond \(E_c\).

One particularity of our stick-slip motions concerns a complete absence of aftershocks following the largest events, as shown in Fig. 13 for a temporal segment of 500 to 1000 seconds on the stress plateau at 400 kPa of confining pressure, successively full water-saturated sample (top), dry (middle) and wet (bottom) with deviatoric stress (left) and synchronized vertical top cap acceleration (right) at full vertical scale, up to 100 g. The insets show a large number of very small vertical acceleration of only 0.2 g preceding each stick-slip, following by a clear long quiescence after the event, up to 100 seconds. This quiescent period without any measurable vertical acceleration above 0.2 g suggests a very stable and dynamic reorganisation of the granular structure by compaction, as shown for the full saturated case in Fig. 2.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Doanh, T., Nguyên, T.T.T. Towards universality of extended seismic laws with largest labquakes. Acta Geotech. 18, 3027–3042 (2023). https://doi.org/10.1007/s11440-022-01768-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01768-2