Abstract

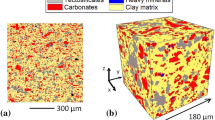

This paper is devoted to study the elastic–plastic damage behavior of heterogeneous shale rocks. The representative microstructure of this kind of rocks is first studied in order to define the representative elementary volume for the implementation of homogenization procedure. Three relevant material scales are considered. Inter-particle pores are distributed at the nanoscopic scale. Fine grains of calcite and kerogen are immersed at the microscopic scale. Large grains of minerals are embedded at the mesoscopic scale. Effective elastic properties of shale rocks are first determined by using a three-step linear homogenization procedure. The plastic damage behavior is estimated by developing a three-step nonlinear homogenization method. The effective plastic behavior of porous clay matrix with nanoscopic pores is described by an analytical model. The effects of small and large grains of various mineral inclusions are investigated by using a two-step incremental model. The damage due to progressive debonding of mineral inclusions is taken into account. After the implementation of the proposed model, comparisons between numerical results and experimental data are presented.

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm FJ (2016a) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation-edx analysis. Acta Geotech 11:559–572

Abedi S, Slim M, Ulm FJ (2016b) Nanomechanics of organic-rich shales: the role of thermal maturity and organic matter content on texture. Acta Geotech 11:775–787

Abou-Chakra Guéry A, Cormery F, Shao JF, Kondo D (2008) A micromechanical model of elastoplastic and damage behaviour of a cohesive geomaterial. Int J Solids Structures 45:1406–1429

Abou-Chakra-Guery A, Cormery F, Shao JF, Kondo D (2010) A comparative micromechanical analysis of the effective properties of a geomaterial: effect of mineralogical compositions. Comput Geotech 37:585–593

Ahmadov RSO (2011) Microtextural, elastic and transport properties of source rocks. PhD thesis, Standford university

Bennett KC, Berla LA, Nix WD, Borja RI (2015) Instrumented nanoindentation and 3d mechanistic modeling of a shale at multiple scales. Acta Geotech 10:1–14

Bennett KC, Luscher DJ, Buechler MA, Yeager JD (2018) A micromechanical framework and modified self-consistent homogenization scheme for the thermoelasticity of porous bonded-particle assemblies. Int J Solids Struct 139–140:224–237

Bobko CP (2008) Assessing the mechanical microstructure of shale by nanoindentation: the link between mineral composition and mechanical properties. PhD thesis, Massachusetts Institute of Technology, Cambridge MA

Borja RI, Yin Q, Zhao Y (2020) Cam-clay plasticity. Part ix: on the anisotropy, heterogeneity, and viscoplasticity of shale. Comput Methods Appl Mech Eng 360:112695

Bornert M, Bretheau T, Gilormini P (2001a) Homogénéisation en mécanique des matétriaux 1. Matériaux aléatoires élastiques et milieux périodiques, Hermes Sciences Europe Ltd

Boulenouar A, Mighani S, Pourpak H, Bernabé Y, Evans B (2017) Mechanical properties of vaca muerta shales from nano-indentation tests. San Francisco, CA, 51th U.S. Rock Mechanics/Geomechanics Symposium, ARMA

Brown JM, Abramson EH, Angel RJ (2006) Triclinic elastic constants for low albite. Phys Chem Miner 33:256–265

Dai LH, Huang GJ (2001) An incremental micromechanical scheme for nonlinear particulate composites. Int J Mech Sci 43:1179–1193

Delafargue A (2004) Material invariant properties of shales: nanoindentation and microporoelastic analysis. PhD thesis, Massachusetts Institute of Technology, Cambridge, MA

Doghri I, Ouaar A (2003) Homogenization of two-phase elastoplastic composite materials and structures: study of tangent operators, cyclic plasticity and numerical algorithms. Int J Solids Struct 40:1681–1712

Farhat F, Shen WQ, Shao JF (2017) A micro-mechanics based viscoplastic model for clayey rocks. Comput Geotech 89:92–102

Gathier B (2008) Multiscale strength homogenization-application to shale nanoindentation. PhD thesis, Massachusetts Institute of Technology, Cambridge, MA

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11(2):127–140

Hill R (1965) Continuum micro-mechanicsof elastoplastic polycrystals. J Mech Phys Solids 13:89–101

Hornby B, Schwartz L, Hudson J (1994) Anisotropic effective medium modeling of the elastic properties of shales. Geophysics 59:1570–1583

Jakobsen M, Hudson JA, Johansen TA (2003) T-matrix approach to shale acoustics. Geophys J Int 154:533–558

Ju JW, Lee HK (2000) A micromechanical damage model for effective elastoplastic behavior of ductile matrix composites considering evolutionary complete particle debonding. Comput Methods Appl Mech Eng 183:201–222

Kumar V, Curtis ME, Gupta N, Sondergeld CH, Rai CS (2012) Estimation of elastic properties of organic matter in woodford shale through nanoindentation measurements. In SPE Canadian unconventional resources conference, society of petroleum engineers, Calgary, Alberta, Canada, 30 October–1 November

Lide DR (2004) Handbook of chemistry and physics. CRC Press, New York

Lucier AM, Hofmann R, Bryndzia LT (2011) Evaluation of variable gas saturation on acoustic log data from the haynesville shale gas play, nw louisiana, usa. Lead Edge 30:300–311

Mori T, Tanaka K (1973) Average stress in a matrix and average elastic energy of materials with misfitting inclusions. Acta Metall Mater 42:597–629

Niandou H, Shao JF, Henry JP, Fourmaintraux D (1997) Laboratory investigation of the mechanical behaviour of tournemire shale. Int J Rock Mech Min Sci 34:3–16

Qin X, Han DH, Zhao L (2014). Rock physics modeling of organic-rich shales with different maturity levels. In: SEG technical program expanded abstracts

Semnani SJ, White JA, Borja RI (2016) Thermoplasticity and strain localization in transversely isotropic materials based on anisotropic critical state plasticity. Int J Numer Anal Meth Geomech 40:2423–2449

Shen WQ, Shao JF (2015) A micro-macro model for porous geomaterials with inclusion debonding. Int J Damage Mech 24:1026–1046

Shen WQ, Shao JF (2016) An incremental micro-macro model for porous geomaterials with double porosity and inclusion. Int J Plast 83:37–54

Shen WQ, Shao JF, Kondo D, Gatmiri B (2012) A micro-macro model for clayey rocks with a plastic compressive porous matrix. Int J Plast 36:64–85

Shen WQ, Kondo D, Dormieux L, Shao JF (2013) A closed-form three scale model for ductile rocks with a plastically compressible porous matrix. Mech Mater 59:73–86

Shen WQ, Zhang J, Shao JF, Kondo D (2017) Approximate macroscopic yield criteria for Drucker-Prager type solids with shperoidal voids. Int J Plast 99:221–247

Su K, Onaisi A, Galeazzi S (2014) Geomechanical characterization and fracability assessment of the vaca muerta shale play. Mendoza City, Argentina, 3–7 November, CONEXPLO

Tohgo K, Weng GJ (1994) A progress damage mechanics in particle-reinforced metal-matrix composites under high triaxial tension. J Eng Mater Technol 116:414–420

TOTAL. http://csr-analysts.total.com.

TOTAL (2012) Geomechanical characterization of Vaca Muerta gas shale formation in view of hydraulic fracturing stimulation

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Zeszotarski JC, Chromik RR, Vinci RP, Messmer MC, Michels R, Larsen JW (2004) Imaging and mechanical property measurements of kerogen via nanoindentation. Geochim Cosmochim Acta 68:4113–4119

Zhang Q, Choo J, Borja RI (2019) On the preferential flow patterns induced by transverse isotropy and non-darcy flow in double porosity media. Comput Methods Appl Mech Eng 353:570–592

Zhao Y, Semnani SJ, Yin Q, Borja RI (2018) On the strength of transversely isotropic rocks. Int J Numer Anal Meth Geomech 42:1917–1934

Zhao YH, Weng GJ (1995) A theory of inclusion debonding and its influence on the stress-strain relations of a ductile matrix. Int J Damage Mech 4:196–211

Acknowledgements

This study has been supported by the Scientific and Technical Center of TOTAL in Pau.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices: Algorithm for local integration of the clay phase

The algorithm for local integration of the elastoplastic damage clay phase is presented in this paragraph for a step (n+1) or at time \(t_{n+1}= t_n+dt_{n+1}\) as follows:

-

1.

Input data: \({\tilde{\varvec{\varepsilon}}}_{0,n},~{\tilde{\varvec{\varepsilon}}}_{0,n}^p,~\varepsilon _{n}^p\;{\text {and}}\;~\Delta {\tilde{\varvec{\varepsilon}}}_0 \);

-

2.

Calculating the deformation at step \(n+1\) : \({\tilde{\varvec{\varepsilon}}}_{0,n+1}= {\tilde{\varvec{\varepsilon}}}_{0,n} +\Delta {\tilde{\varvec{\varepsilon}}}_0\);

-

3.

Initialize (elastic prediction): For \(i = 0\)

$$ \left\{ {\begin{array}{*{20}l} {\tilde{\varepsilon }_{{0,n + 1}}^{{p,0}} = {\text{ }}\tilde{\varepsilon }_{{0,n}}^{p} } \hfill \\ {\tilde{\sigma }_{{n + 1}}^{0} = \mathbb{C}_{0} :(\tilde{\varepsilon }_{{0,n + 1}} - \tilde{\varepsilon }_{{0,n + 1}}^{{p,0}} )} \hfill \\ {\Phi (\tilde{\sigma }_{{n + 1}}^{i} ,\varepsilon _{{n + 1}}^{{p,i}} ,f) = \Phi _{{n + 1}}^{i} {\text{ }}} \hfill \\ \end{array} } \right. $$ -

4.

If \(\Phi _{n+1}^{i} \le \) 0, then go to step 7; else, go to step 5 for plastic correction:

-

5.

\(\delta (\Delta \lambda )= \frac{\Phi _{n+1}^{i}}{{\frac{\partial \Phi }{\partial {\tilde{\varvec{\sigma }}}}:{\mathbb {C}}_0:\frac{\partial G}{\partial {\tilde{\varvec{\sigma }}}}-\frac{\partial \Phi }{\partial f}\left[ \frac{\partial G}{\partial {\tilde{\sigma }}_m}(1-f)-3\alpha _2 \frac{{\tilde{\varvec{\sigma }}}:\frac{\partial G}{\partial {\tilde{\varvec{\sigma }}}}}{\bar{\sigma }+3(\alpha _2-\alpha )\frac{{\tilde{\sigma }}_m}{1-f}} \right] -\frac{\partial \Phi }{\partial \bar{\sigma }}\frac{\partial \bar{\sigma }}{\partial \varepsilon ^p}\frac{{\tilde{\varvec{\sigma }}}:\frac{\partial G}{\partial {\tilde{\varvec{\sigma }}}}}{(1-f)\left[ \bar{\sigma }+3(\alpha _2-\alpha )\frac{{\tilde{\sigma }}_m}{1-f}\right] } }}\)

-

6.

Calculate new values for each iteration:

$$\begin{aligned} {\left\{ \begin{array}{ll} {\tilde{\varvec{\sigma }}}_{n+1}^{i+1} = {\tilde{\varvec{\sigma }}}_{n+1}^{i} - \delta (\Delta \lambda ) {\mathbb {C}}_0 :\frac{\partial G_{n+1}^{i}}{\partial {\tilde{\varvec{\sigma }}}}({\tilde{\varvec{\sigma }}}_{n+1}^{i},\varepsilon _{n+1}^{p,i},f) \\ \varepsilon _{n+1}^{p,i+1}= \varepsilon _{n+1}^{p,i} + \delta (\Delta \lambda ) \frac{{\tilde{\varvec{\sigma }}}:\frac{\partial G}{\partial {\tilde{\varvec{\sigma }}}}}{(1-f)\left[ \bar{\sigma }+3(\alpha _2-\alpha )\frac{{\tilde{\sigma }}_m}{1-f}\right] } \\ \Delta \lambda ^{i+1} = \lambda ^{i} + \delta (\Delta \lambda ) \\ {\tilde{\varepsilon }}_{n+1}^{p,i+1}= {\tilde{\varepsilon }}_{n+1}^{p,i} + \delta (\Delta \lambda ) \frac{\partial G}{\partial {\tilde{\varvec{\sigma }}}} \\ \end{array}\right. } \end{aligned}$$Set \(i= i + 1\) and return to step 4

-

7.

End of Algorithm

Algorithm for the implementation of the proposed three-scale model

Rights and permissions

About this article

Cite this article

Farhat, F., Shen, W.Q., Xie, S.Y. et al. A three-scale micro-mechanical model for elastic–plastic damage modeling of shale rocks. Acta Geotech. 15, 3525–3543 (2020). https://doi.org/10.1007/s11440-020-00983-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-00983-z