Abstract

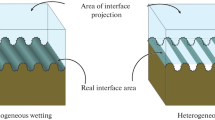

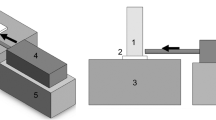

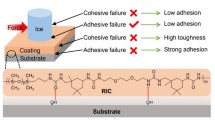

Accurate measurement of the interfacial shear strength between ice and solid surface has important reference significance for the design of anti-icing and de-icing functional surfaces. In this paper, a new method is proposed based on the shear lag model of a single fiber pulled out from matrix, in order to accurately determine the interfacial shear strength (ISS) between ice and metals. The maximum pull-out force at the initiation of interface debonding is well measured in the pull-out test of a metal fiber embedded in an ice matrix. A shear lag model similar to the pull-out test is established and a closed-form relation between the non-uniform interfacial shear stress and the pull-out force is achieved. When the pull-out force reaches its peak value, the ice/metal ISS can be consequently determined as the maximum interfacial shear stress. Such a method takes into account the stress concentration at the interface, which overcomes underestimation of ice/solid ISS based on the apparent strength in previous studies. The achieved ISS is proven to not only have good convergence, but also be independent of the size and embedded depth of metal fibers. Based on the present method, the enhancing effects of freezing temperature and surface roughness on the ice adhesion are further disclosed. The present research provides a simple and reliable approach to accurately calibrate the ice/solid ISS, which should be of important reference significance for the design and assessment of anti-icing functional surfaces.

Similar content being viewed by others

References

Gent R W, Dart N P, Cansdale J T. Aircraft icing. Philos Trans R Soc London Ser A-Math Phys Eng Sci, 2000, 358: 2873–2911

Cao Y, Wu Z, Su Y, et al. Aircraft flight characteristics in icing conditions. Prog Aerospace Sci, 2015, 74: 62–80

Wang Z. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft. Energy Buildings, 2017, 140: 42–49

Luo H, Yin S, Huang S, et al. Fabrication of slippery zn surface with improved water-impellent, condensation and anti-icing properties. Appl Surf Sci, 2019, 470: 1139–1147

Suter L, Streletskiy D, Shiklomanov N. Assessment of the cost of climate change impacts on critical infrastructure in the circumpolar arctic. Polar Geography, 2019, 42: 267–286

Liu X, Chen H, Zhao Z, et al. Slippery liquid-infused porous electric heating coating for anti-icing and de-icing applications. Surf Coatings Tech, 2019, 374: 889–896

Zhao Z, Chen H, Liu X, et al. Development of high-efficient synthetic electric heating coating for anti-icing/de-icing. Surf Coatings Tech, 2018, 349: 340–346

Zhao Z, Chen H, Liu X, et al. Novel sandwich structural electric heating coating for anti-icing/de-icing on complex surfaces. Surf Coatings Tech, 2020, 404: 126489

Zhao Z, Chen H, Liu X, et al. The development of electric heating coating with temperature controlling capability for anti-icing/de-icing. Cold Regions Sci Tech, 2021, 184: 103234

Wang Y, Liu J, Li M, et al. The icephobicity comparison of polysiloxane modified hydrophobic and superhydrophobic surfaces under condensing environments. Appl Surf Sci, 2016, 385: 472–480

Amer M, Wang C C. Review of defrosting methods. Renew Sustain Energy Rev, 2017, 73: 53–74

Lv J, Song Y, Jiang L, et al. Bio-inspired strategies for anti-icing. ACS Nano, 2014, 8: 3152–3169

Höhne S, Hoch C, Böhm C, et al. A new measuring system for the determination of the ice adhesion strength on smooth surfaces. Langmuir, 2020, 36: 4465–4476

Ghalmi Z, Farzaneh M. Durability of nanostructured coatings based on PTFE nanoparticles deposited on porous aluminum alloy. Appl Surf Sci, 2014, 314: 564–569

Jeon J, Jang H, Chang J, et al. Fabrication of micro-patterned aluminum surfaces for low ice adhesion strength. Appl Surf Sci, 2018, 440: 643–650

Zhou C, Zhao X, Zhao X, et al. Low ice adhesion surfaces based on flexible fluorinated polymers with a polynorbornene backbone. ACS Appl Mater Interfaces, 2020, 12: 53494–53502

Golovin K, Kobaku S P R, Lee D H, et al. Designing durable ice-phobic surfaces. Sci Adv, 2016, 2: e1501496

Meuler A J, Smith J D, Varanasi K K, et al. Relationships between water wettability and ice adhesion. ACS Appl Mater Interfaces, 2010, 2: 3100–3110

Chen J, Dou R, Cui D, et al. Robust prototypical anti-icing coatings with a self-lubricating liquid water layer between ice and substrate. ACS Appl Mater Interfaces, 2013, 5: 4026–4030

Yeong Y H, Wang C, Wynne K J, et al. Oil-infused superhydrophobic silicone material for low ice adhesion with long-term infusion stability. ACS Appl Mater Interfaces, 2016, 8: 32050–32059

Li T, Zhuo Y, Håkonsen V, et al. Durable low ice adhesion foams modulated by submicrometer pores. Ind Eng Chem Res, 2019, 58: 17776–17783

Kim J H, Kim M J, Lee B, et al. Durable ice-lubricating surfaces based on polydimethylsiloxane embedded silicone oil infused silica aerogel. Appl Surf Sci, 2020, 512: 145728

He Z, Vågenes E T, Delabahan C, et al. Room temperature characteristics of polymer-based low ice adhesion surfaces. Sci Rep, 2017, 7: 42181

Palacios A M, Palacios J L, Sánchez L. Eliciting a human understandable model of ice adhesion strength for rotor blade leading edge materials from uncertain experimental data. Expert Syst Appl, 2012, 39: 10212–10225

Laforte C, Beisswenger A. Icephobic material centrifuge adhesion test. In: Proceedings of the 11th International Workshop on Atmospheric Icing of Structures, Montréal, 2005. 1–6

Kulinich S A, Farzaneh M. On Ice-releasing properties of rough hydrophobic coatings. Cold Regions Sci Tech, 2011, 65: 60–64

Coady M J, Wood M, Wallace G Q, et al. Icephobic behavior of uv-cured polymer networks incorporated into slippery lubricant-infused porous surfaces: Improving slips durability. ACS Appl Mater Interfaces, 2018, 10: 2890–2896

Raraty L, Tabor D. The adhesion and strength properties of ice. Proc R Soc A-Math Phys Eng Sci, 1958, 245: 184–201

Andersson L O, Golander C G, Persson S. Ice adhesion to rubber materials. J Adhes Sci Tech, 1994, 8: 117–132

Susoff M, Siegmann K, Pfaffenroth C, et al. Evaluation of icephobic coatings—screening of different coatings and influence of roughness. Appl Surf Sci, 2013, 282: 870–879

Akitegetse C, Volat C, Farzaneh M. Measuring bending stress on an ice/aluminium composite beam interface using an embedded piezoelectric PVDF (polyvinylidene-fluoride) film sensor. Meas Sci Technol, 2008, 19: 065703

Sarkar D K, Farzaneh M. Superhydrophobic coatings with reduced ice adhesion. J Adhes Sci Tech, 2009, 23: 1215–1237

Javan-Mashmool M, Volat C, Farzaneh M. A new method for measuring ice adhesion strength at an ice-substrate interface. Hydrol Process, 2010, 20: 645–655

Work A, Lian Y. A critical review of the measurement of ice adhesion to solid substrates. Prog Aerospace Sci, 2018, 98: 1–26

Wang C, Zhang W, Siva A, et al. Laboratory test for ice adhesion strength using commercial instrumentation. Langmuir, 2014, 30: 540–547

Bismarck A, Menner A, Kumru M E, et al. Poly(carbazole-co-acrylamide) electrocoated carbon fibers and their adhesion behavior to an epoxy resin matrix. J Mater Sci, 2002, 37: 461–471

Rønneberg S, He J, Zhang Z. The need for standards in low ice adhesion surface research: A critical review. J Adhes Sci Tech, 2019, 34: 319–347

Chua P S, Piggott M R. The glass fibre-polymer interface: I—theoretical consideration for single fibre pull-out tests. Compos Sci Tech, 1985, 22: 33–42

Jiang K R, Penn L S. Improved analysis and experimental evaluation of the single filament pull-out test. Compos Sci Tech, 1992, 45: 89–103

Yao Y, Chen S. Effects of the longitudinal surface roughness on fiber pull-out behavior in carbon fiber-reinforced epoxy resin composites. J Appl Mech, 2013, 80: 021015

Fu S Y, Lauke B, Mäder E, et al. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos Part A-Appl Sci Manuf, 2000, 31: 1117–1125

Bader M G, Bowyer W H. The mechanical properties of thermoplastics strengthened by short discontinuous fibres. J Phys D-Appl Phys, 1972, 5: 2215–2225

Isla F, Ruano G, Luccioni B. Analysis of steel fibers pull-out. Experimental study. Const Building Mater, 2015, 100: 183–193

Chandran M S, Padmanabhan K, Dipin Raj D K, et al. A comparative investigation of interfacial adhesion behaviour of polyamide based self-reinforced polymer composites by single fibre and multiple fibre pull-out tests. J Adhes Sci Tech, 2020, 34: 511–530

Pakravan H R, Memarian F, Jamshidi M. Macro-polyolefin fiber pull-out behaviour from HPC matrix: Evaluation of type of surface treatment. Eur J Environ Civil Eng, 2020, 24: 1522–1532

Hauch K, Maryamh K, Redenbach C, et al. Predicting the tensile behaviour of ultra-high performance fibre-reinforced concrete from single-fibre pull-out tests. Materials, 2022, 15: 5085

Fu S Y, Yue C Y, Hu X, et al. Analyses of the micromechanics of stress transfer in single- and multi-fiber pull-out tests. Compos Sci Tech, 2000, 60: 569–579

Deng K, Feng X, Tan X, et al. Experimental research on compressive mechanical properties of ice under low strain rates. Mater Today Commun, 2020, 24: 101029

Luo W, Dan H, Zeng R, et al. Experimental investigation on uniaxial unconfined compressive properties of ice on asphalt pavement surface. Front Mater, 2020, 7: 294

Mohamed A M A, Farzaneh M. An experimental study on the tensile properties of atmospheric ice. Cold Regions Sci Tech, 2011, 68: 91–98

Petrovic J. Mechanical properties of ice and snow. J Mater Sci, 2003, 38: 1–6

Gold L W. On the elasticity of ice plates. Can J Civ Eng, 1988, 15: 1080–1084

Sundaram P, Corrales J. Brazilian tensile strength of rocks with different elastic properties in tension and compression. Int J Rock Mech Min Sci, 1980, 17: 131–133

Zou M, Beckford S, Wei R, et al. Effects of surface roughness and energy on ice adhesion strength. Appl Surf Sci, 2011, 257: 3786–3792

Dou R, Chen J, Zhang Y, et al. Anti-icing coating with an aqueous lubricating layer. ACS Appl Mater Interfaces, 2014, 6: 6998–7003

Shen Y, Tao H, Chen S, et al. Icephobic/anti-icing potential of superhydrophobic Ti6Al4V surfaces with hierarchical textures. RSC Adv, 2015, 5: 1666–1672

Chen J, Luo Z, Fan Q, et al. Anti-ice coating inspired by ice skating. Small, 2014, 10: 4693–4699

Menini R, Ghalmi Z, Farzaneh M. Highly resistant icephobic coatings on aluminum alloys. Cold Regions Sci Tech, 2011, 65: 65–69

Piggott M. Load Bearing Fibre Composites. 2nd ed. London: Kluwer Academic Publishers, 2002

Sonwalkar N, Shyam Sunder S, Sharma S K. Ice/solid adhesion analysis using low-temperature raman microprobe shear apparatus. Appl Spectrosc, 1993, 47: 1585–1593

Yao Y, Chen S, Chen P. The effect of a graded interphase on the mechanism of stress transfer in a fiber-reinforced composite. Mech Mater, 2013, 58: 35–54

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12032004, 12272043, 12293000, and 12293002).

Supporting Information

The supporting information is available online at tech.scichina.com and link.springer.com. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Rights and permissions

About this article

Cite this article

Huang, J., Li, D., Peng, Z. et al. A new method based on the shear lag model for accurate determination of ice adhesion shear strength on solid surface. Sci. China Technol. Sci. 66, 987–997 (2023). https://doi.org/10.1007/s11431-022-2202-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2202-2