Abstract

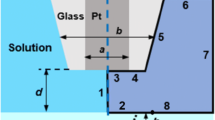

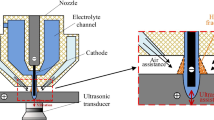

By introducing the mechanical motion into the confined etchant layer technique (CELT), we have developed a promising ultra-precision machining method, termed as electrochemical mechanical micromachining (ECMM), for producing both regular and irregular three dimensional (3D) microstructures. It was found that there was a dramatic coupling effect between the confined etching process and the slow-rate mechanical motion because of the concentration distribution of electrogenerated etchant caused by the latter. In this article, the coupling effect was investigated systemically by comparing the etchant diffusion, etching depths and profiles in the non-confined and confined machining modes. A two-dimensional (2D) numerical simulation model was proposed to analyze the diffusion variations during the ECMM process, which is well verified by the machining experiments. The results showed that, in the confined machining mode, both the machining resolution and the perpendicularity tolerance of side faces were improved effectively. Furthermore, the theoretical modeling and numerical simulations were proved valuable to optimize the technical parameters of the ECMM process.

Similar content being viewed by others

References

Weingarten KJ, Rodwell MJW, Bloom DM. IEEE J Quantum Electron, 1988, 24: 198–220

Curtice WR. IEEE Trans Microwave Theor Technol, 1980, 28: 448–456

Yeh HJJ, Smith JS. IEEE Photon Technol Lett, 1994, 6: 706–708

Köck A, Gornik E, Hauser M, Beinstingl W. Appl Phys Lett, 1990, 57: 2327–2329

Haase MA, Qiu J, Depuydt JM, Cheng H. Appl Phys Lett, 1991, 59: 1272–1274

Larson MC, Kondow M, Kitatani T, Nakahara K, Tamura K, Inoue H, Uomi K. IEEE Photon Technol Lett, 1998, 10: 188–190

Nakayama K, Tanabe K, Atwater HA. Appl Phys Lett, 2008, 93: 121904

Olson JM, Kibbler A, Gessert T. Sol Cells, 1987, 21: 450–451

Konagai M, Sugimoto M, Takahashi K. J Cryst Growth, 1978, 45: 277–280

Venkatesan T, Wilkens B, Lee YH, Warren M, Olbright G, Gibbs HM, Peyghambarian N, Smith JS, Yariv A. Appl Phys Lett, 1986, 48: 145–147

Woodward TK, Chirovsky LMF, Lentine AL, D’Asaro LA, Laskowski EJ, Focht M, Guth G, Pei SS, Ren F, Przybylek GJ, Smith LE, Leibenguth RE, Asom MT, Kopf RF, Kuo JM, Feuer MD. IEEE Photon Technol Lett, 1992, 4: 614–617

Smith AV, Do BT. Appl Opt, 2008, 47: 4812–4832

Samant AN, Dahotre NB. J Eur Ceram Soc, 2009, 29: 969–993

Davis KM, Miura K, Sugimoto N, Hirao K. Opt Lett, 1996, 21: 1729–1731

Giannuzzi LA, Stevie FA. Micron, 1999, 30: 197–204

Reyntjens S, Puers R. J Micromech Microeng, 2001, 11: 287–300

Utke I, Hoffmann P, Melngailis J. J Vac Sci Technol B, 2008, 26: 1197–1276

Deng J, Lee T. Ceram Int, 2000, 26: 825–830

Ekmekci B, Sayar A, Öpöz TT, Erden A. J Micromech Microeng, 2009, 19: 105030

Dornfeld D, Min S, Takeuchi Y. CIRP Ann, 2006, 55: 745–768

Yan Y, Hu Z, Zhao X, Sun T, Dong S, Li X. Small, 2010, 6: 724–728

Yan Y, Xue B, Hu Z, Wu D. Int J Adv Manuf Technol, 2016, 84: 2037–2046

Geng Y, Yan Y, Brousseau EB, Yu B, Qu S, Hu Z, Zhao X. Precision Eng, 2016, 46: 288–300

Yan Y, Zhang J, Xu P, Miao P. RSC Adv, 2017, 7: 11969–11978

Yan Y, Sun T, Liang Y, Dong S. Int J Mach Tools Manu, 2007, 47: 1651–1659

Yan Y, Geng Y, Hu Z. Int J Mach Tools Manu, 2015, 99: 1–18

He Y, Yan Y, Geng Y, Brousseau E. Appl Surf Sci, 2018, 427: 1076–1083

Zantye PB, Kumar A, Sikder AK. Mater Sci Eng-R-Rep, 2004, 45: 89–220

Moon Y. Advances in Chemical Mechanical Planarization (CMP). Cambridge: Woodhead Publishing, 2016. 3–26

Zhan D, Han L, Zhang J, He Q, Tian ZW, Tian ZQ. Chem Soc Rev, 2017, 46: 1526–1544

Wilson JF. Practice and Theory of Electrochemical Machining. New York: John Wiley & Sons. Inc., 1971

Bhattacharyya B, Mitra S, Boro AK. Robot Comp, 2002, 18: 283–289

Wang FF, Wang W, He X, Han L, Zhou JZ, Tian ZQ, Tian ZW, Zhan D. Sci China Chem, 2017, 60: 649–655

Zhan D, Han L, Zhang J, Shi K, Zhou JZ, Tian ZW, Tian ZQ. Acc Chem Res, 2016, 49: 2596–2604

Han L, He Q, Zhao X, Cao Y, Hu Z, Yan Y, Tian Z, Zhan D. Sci Sin Chim, 2017, 47: 594–602

Yuan Y, Han L, Huang D, Su JJ, Tian ZQ, Tian ZW, Zhan D. Electrochim Acta, 2015, 183: 3–7

Yuan Y, Han L, Zhang J, Jia J, Zhao X, Cao Y, Hu Z, Yan Y, Dong S, Tian ZQ, Tian ZW, Zhan D. Faraday Disc, 2013, 164: 189–197

Huang P, Lai J, Han L, Yang FZ, Jiang LM, Su JJ, Tian ZW, Tian ZQ, Zhan D. Sci China Chem, 2016, 59: 1525–1528

Cao Y, Jia Y, Yan Y, Han L, Zhao X, Hu Z, Zhan D. Int J Nanomanuf, 2017, In press

Zhang J, Jia J, Han L, Yuan Y, Tian ZQ, Tian ZW, Zhan D. J Phys Chem C, 2014, 118: 18604–18611

Tian Z, Fen Z, Tian Z, Zhuo X, Mu J, Li C, Lin H, Ren B, Xie Z, Hu W. Faraday Disc, 1992, 94: 37–44

Zhang L, Ma X, Zhuang J, Qiu C, Du C, Tang J, Tian Z. Adv Mater, 2007, 19: 3912–3918

Acknowledgements

This work was supported by the National Natural Science Foundation of China (21573054, 21327002, 91323303, 21621091), the Joint Funds Key Project of the National Natural Science Foundation of China (U1537214), the State Key Program of National Natural Science of China (51535003), Self-Planned Task (SKLRS201606B) of State Key Laboratory of Robotics and System (HIT) and the Open Project of the State Key Laboratory for Manufacturing Systems Engineering (Xi’an Jiaotong University).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Han, L., Jia, Y., Cao, Y. et al. The coupling effect of slow-rate mechanical motion on the confined etching process in electrochemical mechanical micromachining. Sci. China Chem. 61, 715–724 (2018). https://doi.org/10.1007/s11426-017-9195-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-017-9195-3