Abstract

Microalgae cultivation in wastewater has been widely researched under laboratory conditions as per its potential to couple treatment with biomass production. Currently, only a limited number of published articles consider outdoor and long-term microalgae-bacteria cultivations in real wastewater environmental systems. The scope of this work is to describe microalgal cultivation steps towards high-rate algal pond (HRAP) scalability and identify key parameters that play a major role for biomass productivity under outdoor conditions and long-term cultivations. Reviewed pilot-scale HRAP literature is analysed using multivariate analysis to highlight key productivity parameters within environmental and operational factors. Wastewater treatment analysis indicated that HRAP can effectively remove 90% of NH4+, 70% of COD, and 50% of PO43−. Mean reference values of 210 W m−2 for irradiation, 18 °C for temperature, pH of 8.2, and HRT of 7.7 are derived from pilot-scale cultivations. Microalgae biomass productivity at a large scale is governed by solar radiation and NH4+ concentration, which are more important than retention time variations within investigated studies. Hence, selecting the correct type of location and a minimum of 70 mg L−1 of NH4+ in wastewater will have the greatest effect in microalgae productivity. A high nutrient wastewater content increases final biomass concentrations but not necessarily biomass productivity. Pilot-scale growth rates (~ 0.54 day−1) are half those observed in lab experiments, indicating a scaling-up bottleneck. Microalgae cultivation in wastewater enables a circular bioeconomy framework by unlocking microalgal biomass for the delivery of an array of products.

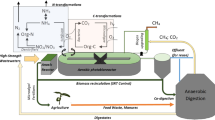

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

During the last 10 years, the use of photosynthetic microalgae has retaken vigour in wastewater treatment research. This is shown by the exponential increase in the number of publications showcased in the literature (Li and Zhu 2021). This reached, in 2023, > 3000 in ScienceDirect and > 17,000 in Google Scholar. Elsevier Scopus database indicates that the main global interest falls in the depletion of carbon dioxide (CO2) and the production of biomass, lipids, and biofuels. Microalgal biomass, grown in wastewater, can have commercial uses, to generate products for the chemical, agricultural, or energy industry (Gong and Bassi 2016; Vassilev and Vassileva 2016; Sudhakar et al. 2019; Bhattacharya and Goswami 2020; Abdelfattah et al. 2023, Walls et al. 2019; González-Balderas et al. 2020a; González-Gálvez et al. 2021; González-Balderas et al. 2020b, c; Romero-Frasca et al. 2021; Montaño San Agustin et al. 2022; Vielma Hernández et al. 2022; Nava-Bravo et al. 2021). Within the chemical sector, recent applications include the production of bioplastics or biocomposites (González-Balderas et al. 2020b; López-Rocha et al. 2020; Cheah et al. 2023).

The potential of microalgae growth is well known, either under phototrophic, mixotrophic, or heterotrophic conditions. Most microalgae naturally grow under photoautotrophic conditions, as they require less energy. Using wastewater instead of the nutrient medium can significantly reduce microalgae cultivation costs, from 2.71 to 0.73 $/kg biomass (Kang et al. 2015), as it can completely replace the use of fresh water and fertilisers (Newby et al. 2016). Different types of wastewaters derived from the domestic, chemical, agricultural, and petrochemical industries have been reported to produce microalgal biomass (Gonçalves et al. 2017; Hernández-García et al. 2019; González-Gálvez et al. 2021; González-Balderas et al. 2020b; Valeriano González et al. 2020; González-Balderas et al. 2021; Romero-Frasca et al. 2021; Montaño San Agustin et al. 2022; Vielma Hernández et al. 2022; Nava-Bravo et al. 2021). Nutrient-rich effluents have also been used as a culture medium for microalgae, such as leachate, centrate, palm oil mill effluent, swine, and poultry wastewater, because of their high nitrogen and phosphorus content (Udaiyappan et al. 2017; Romero et al. 2018; Cheng et al. 2019; Hernández-García et al. 2019; Montaño San Agustin et al. 2022).

Photoautotrophic growth, in wastewater, at the laboratory scale has produced satisfactory results; however, the same microbial strains may not have a successful outcome at large-scale due to complex biological interactions between organisms and the environment. Recently, research has been steered towards understanding the limitations of pilot scale systems (here referred to as capacities > 0.4 m3). Scaling-up under outdoor conditions has so far highlighted the importance of microalgae polycultures, growing medium, and environmental conditions (Novoveská et al. 2016; Chew et al. 2018; 62. Schade and Meier 2019; González-Camejo et al. 2021).

Regarding microalgae polycultures, native species from wastewater are preferred as they are already acclimatised to local environmental conditions. The composition of microalgae-bacteria consortia constantly changes due to fluctuations in temperature, solar irradiation, nutrients, organic load, and pH, which are not homogeneous. Such conditions should be considered in studies using synthetic wastewater (Komolafe et al. 2014; Arango et al. 2016; Chist 2016; Zhang et al. 2016; Salama et al. 2017; Chew et al. 2018; Perera et al. 2019; SundarRajan et al. 2019); otherwise, results would not be comparable to real wastewater conditions.

Figure 1 shows the characteristics of HRAP and a pathway for scaling up. Production starts with cultivations lower than a litre; upscaling is then performed to have enough inoculum to initiate an open raceway system. A harvesting system is finally employed to separate water from the obtained biomass.

Scaling-up of microalgae cultivation and design/operation parameters affecting microalgae growth in HRAP. DO, dissolved oxygen; COD, chemical oxygen demand; pH, potential hydrogen; HRT, hydraulic retention time; NH4+, ammonia; NO3−, nitrogen nitrates; PO43−, orthophosphates; T (°C), temperature (degrees Celsius); solar irradiation is Watts per square metre W m−2

According to the Elsevier Scopus database (2022), around 200 studies related to microalgae cultivation in ponds using wastewater have been published in scientific journals. Most of them were performed in Spain followed by New Zealand and the U.S.A. It should be noted that if search parameters are further specified using words such as “photobioreactor”, “outdoor”, or “large-scale”, the documents obtained are less than 82. Thus, only a few studies have been documented regarding outdoor, long-term, microalgae-focused, wastewater cultivation. Figure 2 shows the location of documented outdoor reactors for wastewater treatment by microalgae-bacteria systems related to solar irradiation. Also, companies that apply this technology for commercial applications are represented in Table 1.

Location of different reported large-scale outdoor reactors for wastewater treatment using microalgae-bacteria consortium. Modified irradiation map in kWh m−2 taken from the worldwide electronic publication Solargis.info 2020—solar resource maps of the world in https://solargis.com/maps-and-gis-data/download/world. The raceway located in Mexico belongs to our research group

Preceding reviews discuss the potential of microalgae growth using wastewater, solely comparing biomass productivities under different types of wastewaters, cultivation systems, nutrient removals, and harvesting technologies (Gupta et al. 2019; Li et al. 2019; SundarRajan et al. 2019; Lu et al. 2020). Those reviews are not specifically directed towards looking into open outdoor reactors, long-term cultivation, and large-scale HRAP systems (> 0.4 m3). Published studies evaluating long-term cultivation of microalgae in large wastewater systems and under outdoor conditions report inconsistent environmental and operational factors (Chist 2016; Novoveská et al. 2016; Zhang et al. 2016). Therefore, it is often difficult to enable quantifiable comparisons. Recently, Nordio et al. (2023) highlighted temperature and irradiance as factors driving biomass productivity—N, P, and COD removals in two open-air pilot-scale HRAP reactors. They highlighted the need to analyse long-term nutrient recovery capacity and biomass productivity using models that include more parameters. This study conducts a profound systematic analysis of current global wastewater pilot-scale HRAP endeavours to identify key conditions needed for successful large-scale cultivations, detect key parameters, and highlight hotspots for process improvement. A meta-analysis was performed considering the following parameters: ammonia nitrogen (NH4+), nitrates (NO3−), orthophosphates (PO43−), chemical oxygen demand (COD), pH, temperature (T°C), hydraulic retention time (HRT), solar radiation and biomass yield, to enable the discussion of environmental and process parameters that improve HRAP performance.

Meta-analysis methodology

A multivariate analysis was carried out with the data obtained from the reviewed articles that met the inclusion criteria. Evaluated articles (Table 2) were statistically analysed for screening key parameters correlated to biomass productivity. Correlation and multiple regression analyses were performed to detect correlations between nutrients, environmental and operational parameters, and biomass production (p < 0.05). All statistical tests were performed with PAST version 4.03, STATGRAPHICS Centurion XVI.I and Minitab 19. The databases used for the search were Elsevier Scopus, ScienceDirect, and Google Scholar where scientific papers were located to ensure access to reliable data. The keywords used were “microalgae wastewater outdoor”, “microalgae wastewater cultivation”, “microalgae wastewater pond”, “wastewater algae raceway”, “microalgae large-scale”, and “microalgae pilot scale”. The databases and the keywords used were only the beginning of the research work; as the work progressed, the spectrum of databases and keywords expanded. Thus, other databases such as PubMed, Web of Science, and other general databases were also consulted. The selected articles were analysed in-depth to determine which ones met the following inclusion criteria: (1) microalgae cultivation in wastewater; (2) cultivation at large-scale (> 0.4 m3); (3) outdoor cultivation and raceways; (4) long-term cultivation (> 2 months); (5) articles that contained data about nutrients (NH4+, NO3−, PO43−, and COD) and microalgae biomass yield; (6) studies with specifications regarding operational and environmental parameters (pH, T °C, HRT, and solar radiation). After a detailed examination of each article, the relevant data, according to the inclusion criteria previously established, were extracted to carry out a meta-analysis. Obtaining information under a systematic framework allowed the standardisation of reported values.

The meta-analysis helped identify key parameters that have the highest impact on biomass production and hotspots. As most of the selected studies reported different units related to solar radiation; to standardise the data, it was decided to obtain this information from NASA Power Data Access Viewer for every location. In the meta-analysis study, reactors operating at ambient conditions and natural solar radiation were considered. The different units were unified according to the international system of units and considering the dimensions of the high-rate algal ponds, respectively. Photosynthetically active radiation (PAR) is a term used to describe radiation in wavelengths useful for photosynthesis of plants. PAR is generally accepted to be wavelengths between 400 a 700 nm. Solar radiation is usually reported in units of μmol m−2 s−1 PAR, W m−2 Μmol m−2 s−1 is an SI unit, and the approximation 1 W m−2 ≈ 4.6 μmol m−2 s−1 (Sager and McFarlane 1997). The parameter “all sky insolation incident on a horizontal surface” was used because it represents the monthly average amount of total solar radiation on the earth’s surface.

Daily biomass areal and volumetric productivities, plus specific growth rates, were calculated using Eqs. 1, 2, and 3, respectively. Specific growth rates refer to the rate of increase of biomass of a cell population per unit of biomass concentration.

Sg stands by specific growth rate; Ct and Co are the biomass or cell densities at time t, and 0, respectively; Vr is the raceway pond volume, HRT is the hydraulic residence time, and the area is the raceway pond area.

A limitation of this meta-analysis is that the number of papers reporting pilot-scale work is not currently vast for scalable microalgae wastewater treatment systems using HRAP. However, most papers tested several conditions which increased the data input in the meta-analysis. Also, studies by De Godos et al. (2009) were not considered as they can bias biomass interpretation. De Godos et al. (2009) reported influent organic concentrations 4 times that of the effluent organic concentrations, so it is highly plausible that not all effluent biomass was algal/bacterial based. Private sector pilot projects (Table 1) were excluded due to a lack of systematic data.

Results and discussion

Wastewater treatment using microalgae for nutrient removal has been studied for more than 50 years. The first studies reported by Caldwell (1946) and Oswald and Gotaas (1957) used microalgae for wastewater treatment in oxidation ponds, demonstrating that their large-scale cultivation could be used for wastewater treatment. The use of oxidation ponds became important to avoid wastewater discharges in freshwater bodies and coastal waters that can cause water eutrophication, leading to serious sanitary and ecological consequences. Since then, conventional wastewater treatment has moved away from microalgal proliferating oxidation ponds to bacterial systems. However, microalgal biomass produced from wastewater has the potential to reduce CO2 emissions, provide water treatment, and generate value-added products.

Table 2 shows 69 HRAP cultivation conditions gathered from 23 scientific articles retrieved from the literature that met the inclusion criteria for the analysis. To optimise yields and productivity in HRAP wastewater treatment, various factors merit consideration, including the careful selection of microalgae for inoculation and subsequent consortia formation. Adaptation to fluctuations in wastewater composition stands as a pivotal determinant. Outdoors, mixed microalgae-bacteria polycultures emerge as the foremost viable option for cultivation, typically characterised by the dominance of a particular microalgae genus. Geographical location, environmental conditions, and the physicochemical properties of the wastewater shape the selection or prevalence of microalgal taxa. Notably efficient genera for wastewater treatment include Chlorella, Scenedesmus, and Chlamydomonas (González-Camejo et al. 2021). The literature reviewed in Table 2 highlights Scenedesmus as the predominant taxon under outdoor conditions. A review by Dolganyuk et al. (2020), based on data from Nancucheo and Johnson’s data (2012), suggests the following: a temperature of 29 °C, a culture duration of 12 days, agitation at 90 rpm, and a pH of 7.1 as optimal culture conditions for Scenedesmus obliquus. However, there is a reported phenomenon wherein the initially dominant taxa can be supplanted by other genera or species as the process unfolds. This transition is particularly pronounced in consortia featuring a diverse array of microalgae. As such, the microalgal taxon was not a parameter included in the metadata analysis, but the information presented in this study provides a guide on the selection of species for outdoor pilot-scale wastewater treatment. The construction of a well-suited microalgae-bacteria consortium via meticulous species selection and establishing an appropriate microalgae-to-bacteria ratio becomes imperative for enhancing wastewater treatment performance. Remarkably, microalgae-bacteria cultures exhibit adaptability to a broad spectrum of environmental parameters, spanning pH, irradiance, temperature, and nutrient concentrations.

Table 2 also shows the change of parameters according to yearly variations. Morillas-España et al. (2021) present a study of reactors installed in Almeria, Spain, and report average and maximum solar radiation and temperature incidences for these seasons: 1200–2000 µmol m−2 s−1 and 26–34 °C. The highest nutrient concentrations (NH4+, PO43−), as well as removal efficiencies and biomass yields, occur during the summer. Overall, the spring to summer seasons provide the most favourable conditions for cultivation, whilst the summer and autumn environmental parameters may require compensation based on location.

The existing literature describes different types of wastewaters that can be treated by microalgae cultivation at the laboratory or pilot scale. Table 3 shows a summary of the type of effluent used in the pilot-scale studies included in this meta-analysis, either combined or individually. The most studied type of wastewater is primarily settled municipal wastewater, followed by anaerobic digestion and treated wastewater. Treated wastewater will have lower concentration of COD than settled wastewater. Of note is the use of anaerobic digestion effluent (digestate) containing high concentrations of nutrients, in particular, rich in ammonia, resulting in a high yield of microalgae biomass as shown in Table 2.

Microalgal physiology and biomass productivity in outdoor cultivation

Microalgal physiology in outdoor cultivation is an aspect that directly influences biomass productivity. During the photosynthetic process, microalgae can consume not only CO2, but also macro- and micronutrients from wastewater, which can result in high growth rates and therefore biomass productivity (Santos et al. 2019). This has been estimated to be up to 50 times higher than that of grasslands (Chisti 2007). Biomass productivity, particularly in outdoor cultivation, is directly influenced by cell physiology, which is a function of various conditions such as the components of the culture medium (e.g. type of wastewater), pH, temperature, growth phase (culture time), and an efficient harvesting method or even stirring of the culture (Dolganyuk et al. 2020). However, light is an overwhelming factor that has a direct impact on the photosynthetic activity of microalgae (Rincon et al. 2019). Maximum growth occurs during the day, but up to 25% of the biomass produced can be lost during the night through respiration, depending on the light intensity during daytime cultivation and the day and night temperature (Chisti 2007). The absence of light reduces the rate of photosynthesis and thus the conversion of solar energy into chemical energy compounds such as adenosine triphosphate (ATP) and nicotinamide adenine dinucleotide phosphate (NADPH) to support cell growth (Baba and Shiraiwa 2013).

Moreover, excessive light can damage the chlorophyll in microalgal cells. In this sense, microalgae can be classified into photoautotrophic, heterotrophic, and mixotrophic cultures. These are based on how they use light as an energy source for growth. Photoautotrophic: use sunlight as an energy source and CO2 as a carbon source. Heterotrophic: can grow under phototrophic conditions and can also make use of organic carbon in the absence of light. Mixotrophic: cell growth is based on CO2 and organic carbon, so both the photosynthetic and organic substrate pathways must function simultaneously (Li et al. 2016; Rincon et al. 2019; Dolganyuk et al. 2020). Microalgae cultivation in large-scale systems, mainly outdoor, is usually photoautotrophic (Dolganyuk et al. 2020), where the stability of the cultures and hence biomass productivity will be highly dependent on environmental conditions.

Nutrient composition and removals

The use of wastewater for its abundant amount of nutrients for microalgae growth and simultaneously as tertiary wastewater treatment has been widely investigated due to the high removal efficiencies achieved (Li et al. 2019). The use of wastewater saves the cost of nutrient supplementation and enhances the assimilation of organic and inorganic pollutants during microalgal cell metabolism. Nitrogen and phosphorus are the most important nutrients for microalgal growth. Microalgae utilise inorganic and organic nitrogen in the form of nitrate (NO3−), ammoniacal nitrogen (NH4+), and urea (CO(NH2)2). Ammoniacal nitrogen is the preferred source of nitrogen, whilst the form of free phosphorus assimilable by microalgae is orthophosphates (PO43−) (Komolafe et al. 2014). The box plot in Fig. 3a show the concentrations of nitrate (NO3−), ammonia nitrogen (NH4+), and orthophosphate (PO43−) as main nutrients for the growth of microalgae in HRAP.

Box plots of the data collected and calculated from the literature in Table 2, for microalgal growth in wastewater in high-rate ponds. a Chemical oxygen demand and nutrient concentrations (mg L−1) and b removals (%). White lines denote the mean of values

Within the different types of wastewaters used, the highest microalgal biomass yields have been reported when using effluents with high organic loads such as leachate, centrate, and piggery wastewater. However, we can see that ammonia nitrogen loads used in most pilot scale studies are not excessively high, even nitrates, and phosphate concentrations are in the low range. Municipal wastewater effluent normally contains around 30 mg L−1 of ammonia nitrogen; from the data gathered here, wastewater concentrations of ammonia averaged 60 mg L−1, whilst nitrate and phosphate concentrations were ten times lower between 4 and 8 mg L−1. The variations in concentration with respect to the average ammonium values are attributed to the wastewater origin. Orthophosphates and nitrates are consistently present at low concentrations; the latter is considered a second source of nitrogen. Consequently, the removal percentages are relatively proportional to the requirements that microalgae have for each of them. This is related to the elementary composition of microalgae and the minimum requirements of basic nutrients for their growth. Based on the elementary composition of microalgae and from the conservation of mass, the minimal requirement for 1 g microalgal biomass (DW) production might be approximated as 1.83 g of CO2, 0.07 g N, and 0.008 g P (Beal et al. 2012; Romero et al. 2017). As such, to obtain a concentration of 1 g microalgae L−1 of wastewater requires a minimum of 70 mg L−1 of N and 8 mg L−1 P.

COD utilised is in the range of 150 to 450 mg L−1 which is a typical interval for municipal wastewater. Additionally, COD can be considered an indicator of the overall removal of contaminant matter in raceway-type wastewater lagoons. The variations with respect to the average % removal can be attributed to the complexity of the wastewater used. HRAP can effectively remove 90% of NH4+, 70% of COD, and 50% of PO43− from wastewater (Fig. 3b). The highest removals are obtained for ammonia, followed by COD, and finally phosphate.

Effect of wastewater, operational, and environmental factors on biomass yield productivity

Figure 4 shows environmental conditions mainly used in pilot scale studies. Whilst microalgae irradiation has a mean of 210 W m−2 or 962 μmol m−2 s−1 which is a normal average for most countries in the world (Fig. 2). Open systems report an average HRT between 5 and 10 days (with a mean of 7.7, Table 2), a similar range is also observed for closed systems. Temperature utilised lies between 12 and 24 °C with a mean of 18 °C and pH between 8 and 9, with a mean of 8.2. The range of temperatures used corresponds to countries with daily total irradiations between 6 and 9 kWh m−2. An alkaline pH is expected as microalgae growth produces hydroxyl ions (Eze et al. 2018). The biomass productivity of the algae culture decreases with an excessive increase in pH of the medium, which causes ammonia volatilisation and a decreased carbon uptake. According to Eze et al. (2018), under optimal pH conditions for microalgae cultivation (8.1), a carbon fixation efficiency of about 99% can be achieved. The supply of CO2 from an external source can be used to control pH (8–9) and to compensate for carbon limitations. Studies using primary wastewater and effluents from secondary treatments for microalgae-based treatment have reported average C, N, and P ratios of 100:19:3 and 100:34:7, respectively (Mohsenpour et al. 2021). The intrinsic link between pH and carbon dioxide concentration indicates that on-line monitoring of parameters such as pH is a good option to control an ensure an optimum HRAP performance.

Box plots of irradiation, pH, HRT, and temperature conditions for pilot scale studies depicted in Table 2. All of the 69 evaluated conditions were included for analysis. White lines denote the mean of values. Illumination used the value of 4.57 to convert Watts m−2 to μmol m−2 s−1 (PAR, photosynthetic irradiance radiation) and vice versa

Biomass yield productivities and calculated specific growth rates are depicted in Fig. 5. Volumetric productivity is approximately five times higher than the areal productivity, denoting how the extensive area needed for HRSP decreases areal productivity; reported ranges of microalgal biomass production coupled with wastewater treatment using HRAP vary widely from 5.7 to 40 g m−2 day−1 (Morales-Amaral et al. 2015; Robles et al. 2020; Sutherland et al. 2020a). The largest HRAP reported is a full-scale system using working volumes of 2900 m3 (Sutherland et al. 2020a). However, studies reporting > 0.4 m3 systems are scarce (Table 1). Most of the studies, at large-scale, have been performed at a pilot scale between 0.15 and 8 m3. The calculated specific growth rate has an average of ~ 0.54 day−1 which is half the value reported experimentally of ~ 1 day−1 in previous publications (Wang et al. 2010; Basu et al. 2015). This denotes a significant decrease in microalgae growth when comparing environmental systems to laboratory experiments. This should inform when modelling and scaling-up laboratory data for a larger system implementation. Studies performed on a laboratory scale cannot predict by themselves the performance and capacity of the different strains of microalgae under outdoor conditions where large fluctuations of solar irradiation, temperature, pH, and predation by other microorganisms would be present, and therefore, the species evaluation should be carried under such conditions. Wen et al. (2016) evaluated the scaling-up of Graesiella sp. first cultivated in 10 L reactors under artificial irradiation and subsequently scaled to 30 L reactors under natural conditions of solar irradiation. Changes in environmental conditions produced a decrease in lipid content (from 45 to 34%). García et al. (2017) cultivated Chlorella vulgaris in open photobioreactors using diluted swine wastewater. They compared outdoor and laboratory photobioreactors and observed that phosphorus and total organic carbon removal efficiencies were higher in laboratory conditions, whilst nitrogen removal was higher in outdoor photobioreactors; this removal was mainly attributed to NH4+ volatilisation, since the assimilation in the biomass was only 25 to 44% of the total nitrogen removed.

Biomass productivity and specific growth rates derived from pilot-scale raceway ponds using wastewater. All of the 69 evaluated conditions depicted in Table 2 were included for analysis. White lines denote the mean of values

Pilot-scale studies were mapped to visualise the correlation and prediction of the biomass yield with respect to growth conditions and wastewater concentrations (Fig. 6). Most studies reported multiple parameters per set-up, as such parameters tested are shown for the same authors. Microalgae exposure to environmental conditions has an impact on biomass production. It is observed that Morillas-España et al. (2021) and Posadas et al. (2015) recorded the highest productivities, as they used wastewater with low to medium–high ammonium concentrations and medium to highest irradiation. Both authors report similar daily volumetric productivities (120–169 g m−3 day−1); however, the highest daily areal production (50 g m−2 day−1 obtained by Posadas et al. (2015) stands out. This can be attributed to the small cultivation area used (raceway: 2.7 m2; 0.8 m3), where irradiation and mixing can be enhanced, compared to the one used by Morillas-España et al. (2021) (raceway: 80 m2; 11.8 m3).

A heatmap combining the performance parameters of each pilot-scale microalgal study. All of the 69 evaluated conditions depicted in Table 2 were included. The colour grey denotes that data is absent. Gradients are scaled as a percentage of each parameter’s high (100%, green) or low values (0%, red) to compare them equally

Figure 7 displays a correlogram among 14 variables analysed. With respect to operational and environmental factors on the performance of microalgae grown in wastewater, it was observed that only ammonia concentrations had a positive significant effect on biomass production, whilst nitrate had a negative effect. The correlogram helped initiate investigations towards determining the relationship between variables. It can be seen that volumetric and areal productivities are highly correlated due to their dependency. Also, temperature and illumination plus COD with nutrient concentrations show a high correlation due to their dependant effect.

Correlogram between nutrients, environmental/operational parameters, and microalgae biomass productivity. The red colours indicate a positive correlation whilst blue colours indicate a negative correlation. Label 1 is the illumination factor as PAR, and 14 is the specific growth rate. Variables that have the darkest colours have the highest Pearson correlation coefficients and vice versa

Parameter prediction on biomass yield productivity

Statistical investigations on combined effects on productivity implied the removal of 12 insignificant or dependant variables. It was found that illumination (as PAR) and ammonia concentration were significant, with no convoluted variables that explained 80% of the calculated biomass productivity, whilst the range of changes in HRT had a less significant effect. According to the Pearson correlation, NH4+ and PAR have the greatest impact on biomass production. Multiple regression analyses indicated that 79.94% of the variance (R2) in the analysed dependent variable, biomass volumetric productivity, can be explained by NH4+ and PAR (Fig. 9). The importance of illumination highlights the need to consider the climatic characteristics of the HRAP location. An ideal illumination improves microalgae biomass productivity when cultivated outdoor and at large-scale. Solar radiation directly affects the photosynthetic activity of algae (Arbib et al. 2013) and their growth rate. This directly impacts the regulation of cell proliferation, biocomponent accumulation, and metabolic changes in microalgae, as light quality plays an important role (Hong et al. 2023). Microbial growth rate increases with increasing light intensity, and to verify this relationship, several models have been proposed (Xu et al. 2019). Solar irradiation can also affect CO2 fixation since according to Toro-Huertas et al. (2019), about 30% of the total CO2 fixed by microalgae was carried out at low irradiation. Environmental conditions change over time and not only affect growth but also cause fluctuations in the abundance of species (Newby et al. 2016). Table 2 shows studies performed in different seasons using the same reactor to evaluate how environmental conditions such as solar radiation and temperature influence the biomass production. For example, De Godos et al. (2009) evaluated the performance of two 464 L HRAP under different climatic conditions from January to October, and they found that the optimum environmental conditions were from July to September, producing the highest biomass yield of 1.33 g L−1. During this period, the temperature and solar radiation were higher compared to the January–June period. Following the same line, Sutherland et al. (2020a) assessed the performance of three different-size HRAPs over three seasons and reported the highest biomass yield during the summer.

Figure 8 showcases the effect of PAR and NH4+ concentrations on biomass productivity. It can be seen that the highest irradiation and low to medium ammonia concentrations produced the highest volumetric productivities. The high productivities depicted at low ammonia concentrations in Fig. 8a are considered to be an artefact. Overall, reported conditions are well represented in the response surface plots, about 94% of reports analysed use low to medium–high ammonium concentrations (50–170 mg L−1) and low to medium–high illumination values (430–1300 Watts m−2), with an average volumetric productivity between 50 and 100 g m−3 day−1.

Effect of illumination and ammonia concentration in daily volumetric productivity. a Contour plot from obtained data obtained in Table 2. b Regression plot derived from the analysis of variables (R2 = 80%). Green data points represent individual information used for analyses. Illumination is expressed as Photosynthetic Irradiance Radiation (PAR) and ammonia concentration is in mg L−1. Illumination used the value of 4.57 to convert Watts m−2 to μmol m−2 s−1 and vice versa

Validation of prediction factors

Validation was conducted via the analysis of residual plots obtained from the correlation equation (Fig. 9); it can be seen that they follow a normal distribution. The normal probability plot shows the correlation of data according to the regression performed. Residual vs. fitted value shows that values are randomly distributed. The histogram shows a normal bell shape. Residual vs. observation order shows an aleatory order. According to the coefficients table displayed in Minitab, the value of the variance inflation factor (VIF) for significant variables was < 5 indicating no multicollinearity. To achieve this, it was necessary to perform several prior analyses to eliminate 12 insignificant or dependent correlated variables. As a result, it can be assumed that the regression model obtained using the two main variables fits the data well (NH4+ and PAR).

HRAP vs. other microalgae cultivation systems

The two major microalgal cultivation systems for wastewater treatment are classified as open and closed (Chew et al. 2018; González-Camejo et al. 2021). There is also a third cultivation mode that uses both open and closed systems, known as hybrid systems (Cai et al. 2013; Razzak et al. 2017). Open systems are generally cultivated outdoors, whilst closed systems are usually cultivated indoors, although several studies report closed systems that are exposed to sunlight and ambient temperature (Molazadeh et al. 2019). At the pilot scale, open systems such as raceway reactors are presented as a viable technology for microalgae wastewater treatment, as they offer easy maintenance, higher operating volumes, and lower energy consumption, producing a similar microbial growth rate than closed systems, making them economically attractive (Morillas-España et al. 2021; Nordio et al. 2023). Our study aligns with literature that reports solar radiation and temperature to largely determine the success of pilot-scale open systems using high-capacity ponds. However, both variables are dependent on each other; therefore, only one can be used to predict productivity. It should be noted that open pond cultures are subject to inherent factors such as easy contamination, rapid water evaporation, and large surface occupancy. In addition, the stability of microalgal cultures and biomass yields may be affected by their susceptibility to contamination by competing organisms or predators such as rotifers (Kim et al. 2017; Jebali et al. 2018; Ma et al. 2018; Galès et al. 2019).

Contamination in hybrid systems can be significantly reduced compared to open systems. Hybrid systems create a two-staged growing cycle that can generate microalgal biomass in a rapid and controlled manner, which is then transferred to an open reactor. Hybrid systems include the plate reactors, tubular reactors, ring reactors, and airlift plate reactors. Here, photobioreactors are used to produce inoculum under controlled conditions, which are used for the cultivation of algae in open ponds, to reduce pollution problems and maintain species dominance (Cai et al. 2013). Recently, De Assis et al. (2020) proposed the use of biofilm reactors (BR) as an algal biomass production and harvesting unit, coupled with a HRAP, as a wastewater treatment unit. Under this approach, biomass production was achieved about 2.6 times higher than the conventional system without BR, and the harvesting efficiency of the hybrid system was 61%, compared to 22% obtained with the conventional system. The photobioreactor promoted an increase in density (~ 1,011 org m−2) and diversity of microalgae in the hybrid system and did not interfere with wastewater treatment. Economic analyses of the application of photobioreactors in hybrid systems are needed to enable their large-scale implementation.

Conclusions

A multivariate analysis can assist in identifying key growth parameters within a series of environmental and operational factors. Correlation and multiple regression analyses undertaken suggest that among all parameters reported that influence biomass production, the key parameters are NH4+ and illumination (PAR). The content of NH4+ can be manipulated and controlled in reactors by using wastewater with a moderate ammonium-nitrogen content. Using compounds such as swine, poultry wastewater or digestate of food waste increases final biomass concentrations but does not necessarily result in an increased productivity. The production of microalgal biomass at a large scale using wastewater has a great synergistic potential as HRAP can remove 90%, 70%, and 50% of the NH4, COD, and PO4 content, respectively. With respect to the systems used for cultivation, HRAP are still preferred despite their low productivity, mainly due to the low construction and operation costs. A strategy to implement for these open systems is to select an ideal location and cultivation season and create a hybrid growing system. Further research is needed on hybrid culture systems to dictate how a closed photobioreactor can improve high-rate algal pond performance on a larger scale. Scaling up algal cultures from laboratory to outdoor production is still a challenge because it not only depends on operational and environmental factors but also requires the maintenance of biological cultures for long periods. For example, microbial-specific growth rates halved in pilot scale studies versus lab experiments indicating a scaling-up hotspot. This could be overcome through the construction of an adequate microalgae-bacteria consortia, provision of maximum solar illumination, and possibly enabling CO2 supply. Maintaining a balance between limiting carbon and nutrient sources such as NH4 and CO2 of microalgae (C:N:P) is imperative. The on-line monitoring of pH is recommended so that potential problems can be early detected, improving culture stability and avoiding culture collapse.

Ultimately, cultivation of microalgae in wastewater remains an emerging field in which careful considerations should be cost-effectively implemented to sustain long-term cultivations and wastewater treatment. Future studies are recommended to systematically compare different pilot-scale reactor designs and their associated process economics.

Data availability

Datasets can be found in the attached supplementary material, further information can be made available upon request.

Code availability

Not applicable.

References

Abdelfattah A, Ali SS, Ramadan H, El-Aswar EI, Eltawab R, Ho SH, Elsamahy T, Li S, El-Sheekh MM, Schagerl M, Kornaros M, Sun J (2023) Microalgae-based wastewater treatment: mechanisms, challenges, recent advances, and future prospects. Environ Sci Ecotech 13:100205. https://doi.org/10.1016/j.ese.2022.100205

Arango L, Cuervo FM, González-Sánchez A, Buitrón G (2016) Effect of microalgae inoculation on the startup of microalgae–bacteria systems treating municipal, piggery and digestate wastewaters. Water Sci Technol 73(3):687–696. https://doi.org/10.2166/wst.2015.544

Arashiro LT, Ferrera I, Rousseau DPL, Van Hulle SWH, Garfí M (2019) The effect of primary treatment of wastewater in high-rate algal pond systems: biomass and bioenergy recovery. Bioresource Technol 280:27–36. https://doi.org/10.1016/j.biortech.2019.01.096

Arbib Z, Ruiz J, Álvarez-Díaz P, Garrido-Pérez C, Barragan J, Perales JA (2013) Long term outdoor operation of a tubular airlift pilot photobioreactor and a high-rate algal pond as tertiary treatment of urban wastewater. Ecol Eng 52:143–153. https://doi.org/10.1016/j.ecoleng.2012.12.089

Arbib Z, de Godos I, Ruiz J, Perales JA (2017) Optimization of pilot high-rate algal ponds for simultaneous nutrient removal and lipids production. Sci Total Environ 589:66–72. https://doi.org/10.1016/j.scitotenv.2017.02.206

Baba M, Shiraiwa Y (2013) Biosynthesis of lipids and hydrocarbons in algae. In: Dubinsky Z (ed) Photosynthesis. Intech Open, London, pp 332–356. https://doi.org/10.5772/56413

Basu S et al (2015) Operational strategies for maximizing CO2 utilization efficiency by the novel microalga Scenedesmus obliquus SA1 cultivated in lab scale photo- bioreactor. Algal Res 12:249–257. https://doi.org/10.1016/j.algal.2015.09.010

Beal CM, Hebner RE, Webber ME, Ruoff RS, Seibert AF, King CW (2012) Comprehensive evaluation of algal biofuel production: experimental and target results. Energies 5(6):1943–1981. https://doi.org/10.3390/en5061943

Bhattacharya M, Goswami S (2020) Microalgae - a green multi product biorefinery for future industrial prospects. Biocatal Agri Biotechnol 25:101580. https://doi.org/10.1016/j.bcab.2020.101580

Cai T, Park SY, Li Y (2013) Nutrient recovery from wastewater streams by microalgae: status and prospects. Renew Sust Energ Rev 19:360–369. https://doi.org/10.1016/j.rser.2012.11.030

Caldwell DH (1946) Sewage oxidation ponds: performance, operation and design. Sewage Work J 18(3):433–458 https://www.jstor.org/stable/25030250

Cheah WY, Er AC, Aiyub K, Mohd Yasin NH, Ngan SL, Chew KW, Khoo KS, Ling TC, Juan JC, Ma Z, Show PL (2023) Current status and perspectives of algae-based bioplastics: a reviewed potential for sustainability. Algal Res 71:103078. https://doi.org/10.1016/j.algal.2023.103078

Cheng DL, Ngo HH, Guo WS, Chang SW, Nguyen DD, Kumar SM (2019) Microalgae biomass from swine wastewater and its conversion to bioenergy. Bioresource Technol 275:109–122. https://doi.org/10.1016/j.biortech.2018.12.019

Chew KW, Chia SR, Show PL, Yap YJ, Ling TC, Chang JS (2018) Effects of water culture medium, cultivation systems and growth modes for microalgae cultivation: a review. J Taiwan Inst Chem E 91:332–344. https://doi.org/10.1016/j.jtice.2018.05.039

Chinnasamy S, Bhatnagar A, Hunt RW, Das KC (2010) Microalgae cultivation in a wastewater dominated by carpet mill effluents for biofuel applications. Bioresour Technol 101:3097–3105. https://doi.org/10.1016/j.biortech.2009.12.026

Chist Y (2016) Large-scale production of algal biomass: raceway ponds. In: Bux F, Chisti Y (eds) Algal Biotechnology. Springer International Publishing, Stwizerland, pp 21–40

Chisti Y (2007) Biodiesel from microalgae. In Biotechnology Advances 25(3):294–306. https://doi.org/10.1016/j.biotechadv.2007.02.001

Chuka-ogwude D, Ogbonna J, Borowitzka MA, Moheimani NR (2020) Screening, acclimation and ammonia tolerance of microalgae grown in food waste digestate. J Appl Phycol 32:3775–3785. https://doi.org/10.1007/s10811-020-02276-0

D’Alessandro EB, Filho NRA (2016) Concepts and studies on lipid and pigments of microalgae: a review. Renew Sust Energ Rev 58:832–841. https://doi.org/10.1016/j.rser.2015.12.162

Das P, Quadir MA, Thaher MI, Alghasal GSHS, Aljabri HMSJ (2019) Microalgal nutrients recycling from the primary effluent of municipal wastewater and use of the produced biomass as bio-fertilizer. Int J Environ Sci Te (Tehran) 16:3355–3364. https://doi.org/10.1007/s13762-018-1867-8

De Assis LR, Calijuri ML, Assemany PP, Silva TA, Teixeira JS (2020) Innovative hybrid system for wastewater treatment: high-rate algal ponds for effluent treatment and biofilm reactor for biomass production and harvesting. J Environ Manage 274:111183. https://doi.org/10.1016/j.jenvman.2020.111183

De Godos I, Blanco S, García-Encina AP, Becares E, Muñoz R (2009) Long-term operation of high-rate algal ponds for the bioremediation of piggery wastewaters at high loading rates. Bioresource Technol 100:4332–4339. https://doi.org/10.1016/j.biortech.2009.04.016

Dębowski M, Zieliński M, Kisielewska M, Kazimierowicz J, Dudek M, Świca I, Rudnicka A (2020) The cultivation of lipid-rich microalgae biomass as anaerobic digestate valorisation technology-a pilot-scale study. Processes 8:517. https://doi.org/10.3390/pr8050517

Dogaris I, Loya B, Cox J, Philippidis G (2019) Study of landfill leachate as a sustainable source of water and nutrients for algal biofuels and bioproducts using the microalga Picochlorum oculatum in a novel scalable bioreactor. Bioresource Technol 282:18–27. https://doi.org/10.1016/j.biortech.2019.03.003

Dolganyuk V, Daria B, Olga B, Alexander P, Svetlana I, Dmitry K, Nikolai P, Stanislav S (2020) Microalgae: a promising source of valuable bioproducts. Biomolecules 10:1153. https://doi.org/10.3390/biom10081153

Eland EL, Davenport JR, dos Santos BA, Filho MRC (2019) Molecular evaluation of microalgal communities in full-scale waste stabilisation ponds. Environ Technol 40(15):1969–1976. https://doi.org/10.1080/09593330.2018.1435730

Eze VC, Velasquez-Orta SB, Hernández-García A, Monje-Ramírez I, Orta-Ledesma MT (2018) Kinetic modelling of microalgae cultivation for wastewater treatment and carbon dioxide sequestration. Algal Res 32:131–141. https://doi.org/10.1016/j.algal.2018.03.015

Galès A, Bonnafous A, Carré C, Jauzein V, Lanouguère E, Le Floc'h E, Pinoit J, Poullain C, Roques C, Sialve B, Simier M, Steyer JP, Fouilland E (2019) Importance of ecological interactions during wastewater treatment using high-rate algal ponds under different temperate climates. Algal Res 40:101508. https://doi.org/10.1016/j.algal.2019.101508

García D, Posadas E, Grajeda C, Blanco S, Martínez-Páramo S, Acién G, García-Encina P, Bolado S, Muñoz R (2017) Comparative evaluation of piggery wastewater treatment in algal-bacterial photobioreactors under indoor and outdoor conditions. Bioresource Technol 245:483–490. https://doi.org/10.1016/j.biortech.2017.08.135

García-Galán MJ, Gutiérrez R, Uggetti E, Matamoros V, García J, Ferrer I (2018) Use of full-scale hybrid horizontal tubular photobioreactors to process agricultural runoff. Biosyst Eng 166:138–149. https://doi.org/10.1016/j.biosystemseng.2017.11.016

Gentili FG, Fick J (2017) Algal cultivation in urban wastewater: an efficient way to reduce pharmaceutical pollutants. J Appl Phycol 29:255–262. https://doi.org/10.1007/s10811-016-0950-0

Gerardo ML, Oatley-Radcliffe DL, Lovitt RB (2014) Integration of membrane technology in microalgae biorefineries. J Membrane Sci 464:86–99. https://doi.org/10.1016/j.memsci.2014.04.010

Gonçalves AL, Pires JC, Simões M (2017) A review on the use of microalgal consortia for wastewater treatment. Algal Res 24:403–415. https://doi.org/10.1016/j.algal.2016.11.008

Gong M, Bassi A (2016) Carotenoids from microalgae: a review of recent developments. Biotechnol Adv 34(8):1396–1412. https://doi.org/10.1016/j.biotechadv.2016.10.005

González-Balderas RM, Velásquez-Orta SB, Valdez-Vazquez I, Orta Ledesma MT (2020a) Sequential pretreatment to recover carbohydrates and phosphorus from Desmodesmus sp. cultivated in municipal Wastewater. Water Sci Tech 82(6):1237–1246. https://doi.org/10.2166/wst.2020.404

González-Balderas RM, Felix M, Bengoechea C, Guerrero A, Orta Ledesma MT (2020b) Influence of mold temperature on the properties of wastewater-grown microalgae-based plastics processed by injection molding. Algal Res 51:102055. https://doi.org/10.1016/j.algal.2020.102055

González-Balderas RM, Velásquez-Orta SB, Orta Ledesma MT (2020c) Biorefinery process intensification by ultrasound and ozone for phosphorus and biocompounds recovery from microalgae. Chem Eng Process: Process Intensification 153:107951. https://doi.org/10.1016/j.cep.2020.107951

González-Balderas RM, Felix M, Bengoechea C, Orta Ledesma MT, Guerrero A, Velásquez-Orta SB (2021) Development of composites based on residual microalgae biomass cultivated in wastewater. Eur Polym J 160:110766. https://doi.org/10.1016/j.eurpolymj.2021.110766

González-Camejo J, Ferrer J, Seco A, Barat R (2021) Outdoor microalgae-based urban wastewater treatment: recent advances, applications, and future perspectives. Wiley Interdisciplinary Reviews: Water 8(3):e1518. https://doi.org/10.1002/wat2.1518

Gonzalez-Galvez OD, Nava Bravo I, Cuevas-García R, Velásquez-Orta SB, Harvey AP, Cedeño Caero L, Orta Ledesma MT (2021) Bio-oil production by catalytic solvent liquefaction from a wild microalgae consortium. Biomass Convers Biorefinery 11:2627–2639. https://doi.org/10.1007/s13399-020-00716-y

Gupta S, Pawar SB, Pandey RA (2019) Current practices and challenges in using microalgae for treatment of nutrient rich wastewater from agro-based industries. Sci Total Environ 687:1107–1126. https://doi.org/10.1016/j.scitotenv.2019.06.115

Gutierrez R, Ferrer I, González-Molina A, Garcia J, Uggetti E (2016) Microalgae recycling improves biomass recovery from wastewater treatment high-rate algal ponds. Water Res 106:539–549. https://doi.org/10.1016/j.watres.2016.10.039

Hernández-García A, Velásquez-Orta SB, Novelo M, Yáñez-Noguez I, Monje-Ramírez I, Orta Ledesma MT (2019) Wastewater-leachate treatment by microalgae: biomass, carbohydrate and lipid production. Ecotox Environ Safe 174:435–444. https://doi.org/10.1016/j.ecoenv.2019.02.052

Hong Y, Yang L, You X et al (2023) Effects of light quality on microalgae cultivation: bibliometric analysis, mini-review, and regulation approaches. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-023-31192-2

Iasimone F, Zuccaro G, D’Oriano V, Franci G, Galdiero M, Pirozzi D, De Felice V, Pirozzi F (2018) Combined yeast and microalgal cultivation in a pilot-scale raceway pond for urban wastewater treatment and potential biodiesel production. Water Sci Technol 77(4):062–1070. https://doi.org/10.2166/wst.2017.620

Jebali AF, Acién FG, Barradas RE, Olguín EJ, Sayadi S, Grima ME (2018) Pilot-scale outdoor production of Scenedesmus sp. in raceways using flue gases and centrate from anaerobic digestion as the sole culture medium. Bioresource Technol 262:1–8. https://doi.org/10.1016/j.biortech.2018.04.057

Kang Z, Kim BK, Ramanan R, Choi JE, Yang JW, Oh HM, Kim HS (2015) A cost analysis of microalgal biomass and biodiesel production in open raceways treating municipal wastewater and under optimum light wavelength. J Microbiol Biotechn 25(1):109–118. https://doi.org/10.4014/jmb.1409.09019

Kim D, Kim EK, Koh HG, Kim K, Han JI, Chang YK (2017) Selective removal of rotifers in microalgae cultivation using hydrodynamic cavitation. Algal Res 28:24–29. https://doi.org/10.1016/j.algal.2017.09.026

Komolafe O, Velasquez-Orta SB, Monje-Ramirez I, Yáñez-Noguez I, Harvey AP, Orta Ledesma MT (2014) Biodiesel production from indigenous microalgae grown in wastewater. Bioresource Technol 154:297–304. https://doi.org/10.1016/j.biortech.2013.12.048

Kumar K, Mishra SK, Shrivastav A, Park MS, Yang JW (2015) Recent trends in the mass cultivation of algae in raceway ponds. Renew Sust Energ Rev 51:875–885. https://doi.org/10.1016/j.rser.2015.06.033

Labbé J, Ramos-Suárez JL, Hernández-Pérez A, Baeza A, Hansen F (2017) Microalgae growth in polluted effluents from the dairy industry for biomass production and phytoremediation. J Environ Chem Eng 5(1):635–643. https://doi.org/10.1016/j.jece.2016.12.040

Li Z, Zhu L (2021) The scientometric analysis of the research on microalgae-based wastewater treatment. Environ Sci Pollut Res 28:25339–25348. https://doi.org/10.1007/s11356-021-12348-4

Li T, Kirchhoff H, Gargouri M, Feng J, Cousins AB, Pienkos PT, Gang DR, Chen S (2016) Assessment of photosynthesis regulation in mixotrophically cultured microalga Chlorella sorokiniana. Algal Res 19:30–38. https://doi.org/10.1016/j.algal.2016.07.012

Li K, Liu Q, Fang F, Luo R, Lu Q, Zhou W, Huo S, Cheng P, Liu J, Addy M, Chen P, Chen D, Ruan R (2019) Microalgae-based wastewater treatment for nutrients recovery: a review. Bioresource Technol. https://doi.org/10.1016/j.biortech.2019.121934

López-Rocha CJ, Alvarez-Castillo E, Estrada-Yañez MR, Bengoechea C, Guerrero A, Orta-Ledesma MT (2020) Development of bioplastics from a microalgae consortium from wastewater. J Environ Manage 263:110353. https://doi.org/10.1016/j.jenvman.2020.110353

Lu W, Alam AM, Liu S, Xu J, Parra SR (2020) Critical processes and variables in microalgae biomass production coupled with bioremediation of nutrients and CO2 from livestock farms: a review. Sci Total Environ 716:135247. https://doi.org/10.1016/j.scitotenv.2019.135247

Ma X, Gao M, Gao Z et al (2018) Past, current, and future research on microalga-derived biodiesel: a critical review and bibliometric analysis. Environ Sci Pollut Res 25:10596–10610. https://doi.org/10.1007/s11356-018-1453-0

Mantovani M, Marazzi F, Fornaroli R, Bellucci M, Ficara E, Mezzanotte V (2020) Outdoor pilot-scale raceway as a microalgae-bacteria sidestream treatment in a WWTP. Sci Total Environ 710:135583. https://doi.org/10.1016/j.scitotenv.2019.135583

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sust Energ Rev 14:217–232. https://doi.org/10.1016/j.rser.2009.07.020

Matamoros V, Gutiérrez R, Ferrer I, García J, Bayona JM (2015) Capability of microalgae-based wastewater treatment systems to remove emerging organic contaminants: a pilot-scale study. J Hazard Mater 288:34–42. https://doi.org/10.1016/j.jhazmat.2015.02.002

Min M, Wang L, Li Y, Mohr MJ, Hu B, Zhou W, Chen P, Ruan R (2011) Cultivating Chlorella sp. in a pilotscale photobioreactor using centrate wastewater for microalgae biomass production and wastewater nutrient removal. Appl Biochem Biotech 165:123–137. https://doi.org/10.1007/s12010-011-9238-7

Mohsenpour SF, Hennige S, Willoughby N, Adeloye AJ, Gutierrez T (2021) Integrating micro-algae into wastewater treatment: a review. Sci Total Environ 752:142168. https://doi.org/10.1016/j.scitotenv.2020.142168

Molazadeh M, Ahmadzadeh H, Pourianfar RH, Stephen Lyon S, Rampelotto HP (2019) The use of microalgae for coupling wastewater treatment with CO2 biofixation. Front Bioeng Biotechnol 7:42. https://doi.org/10.3389/fbioe.2019.00042

Montaño San Agustin D, Orta-Ledesma MT, Monje-Ramírez I, Yáñez-Noguez I, Luna-Pabello VM, Velasquez-Orta SB (2022) A non-sterile heterotrophic microalgal process for dual biomass production and carbon removal from swine wastewater. Renew Energ 181:592–603. https://doi.org/10.1016/j.renene.2021.09.028

Morales-Amaral MM, Gómez-Serrano C, Acién FG, Fernández-Sevilla JM, Molina-Grima E (2015) Outdoor production of Scenedesmus sp. in thin-layer and raceway reactors using centrate from anaerobic digestion as the sole nutrient source. Algal Res 12:99–108. https://doi.org/10.1016/j.algal.2015.08.020

Morillas-España A, Lafarga T, Sánchez-Zurano A, Acién-Fernández FG, Rodríguez-Miranda E, Gómez-Serrano C, González-López CV (2021) Year-long evaluation of microalgae production in wastewater using pilot-scale raceway photobioreactors: assessment of biomass productivity and nutrient recovery capacity. Algal Res 60:102500. https://doi.org/10.1016/j.algal.2021.102500

Nancucheo I, Johnson DB (2012) Acidophilic algae isolated from mine-impacted environments and their roles in sustaining hterotrophic acidophiles. Front Microbiol 3(325):1–8. https://doi.org/10.3389/fmicb.2012.00325

Nava-Bravo I, Velasquez-Orta SB, Monje-Ramírez I, Güereca P, Harvey A, Cuevas-García R, Yáñez-Noguez I, Orta-Ledesma MT (2021) Catalytic hydrothermal liquefaction of microalgae cultivated in wastewater: influence of ozone-air flotation on products, energy balance and carbon footprint. Energ Convers Manage 249:114806. https://doi.org/10.1016/j.enconman.2021.114806

Newby DT, Mathews TJ, Pate RC, Huesemann MH, Lane TW, Wahlen BW, Mandal S, Engler RK, Feris KP, Shurin JB (2016) Assessing the potential of polyculture to accelerate algal biofuel production. Algal Res 19:264–277. https://doi.org/10.1016/j.algal.2016.09.004

Nordio R, Delgado FJ, Sánchez-Zurano A, Hernandez JG, Rodríguez-Miranda E, Guzmán JL, Lafarga T, Acién FG (2023) Long-term assessment of the nutrient recovery capacity and biomass productivity of Scenedesmus almeriensis in raceway reactors using unprocessed urban wastewater. Bioresour Tech 369:128374. https://doi.org/10.1016/j.biortech.2022.128374

Novoveská L, Zapata AKM, Zabolotney JB, Atwood MC, Sundstrom ER (2016) Optimizing microalgae cultivation and wastewater treatment in large-scale offshore photobioreactors. Algal Res 18:86–94. https://doi.org/10.1016/j.algal.2016.05.033

Oswald WJ, Gotaas HB (1957) Photosynthesis in sewage treatment. Trans Am Soc Civ Eng 122:73–105

Park JBK, Craggs RJ (2010) Wastewater treatment and algal production in high-rate algal ponds with carbon dioxide addition. Water Sci Technol 1(3):633–639. https://doi.org/10.2166/wst.2010.951

Park JBK, Craggs RJ, Shilton AN (2011) Recycling algae to improve species control and harvest efficiency from a high-rate algal pond. Water Res 45(20):6637–6649. https://doi.org/10.1016/j.watres.2011.09.042

Perera IA, Abinandan S, Subashchandrabose SR, Venkateswarlu K, Naidu R, Megharaj M (2019) Advances in the technologies for studying consortia of bacteria and cyanobacteria/microalgae in wastewaters. Crit Rev Biotechnol 39(5):709–731. https://doi.org/10.1080/07388551.2019.1597828

Podevin M, Fotidis IA, De Francisci D, Møller P, Angelidaki I (2017) Detailing the start-up and microalgal growth performance of a full-scale photobioreactor operated with bioindustrial wastewater. Algal Res 25:101–108. https://doi.org/10.1016/j.algal.2017.04.030

Posadas E, Morales MM, Gomez C, Acién FG, Muñoz R (2015) Influence of pH and CO2 source on the performance of microalgae-based secondary domestic wastewater treatment in outdoors pilot raceways. Chem Eng 265:239–248. https://doi.org/10.1016/j.cej.2014.12.059

Razzak SA, Ali SAM, Hossain MM, deLassa H (2017) Biological CO2 fixation with production of microalgae in wastewater- a review. Renew Sust Energ Rev 76:379–390. https://doi.org/10.1016/j.rser.2017.02.038

Rincon SM, Urrego NF, Avila KJ, Romero HM, Beyenal H (2019) Photosynthetic activity assessment in mixotrophically cultured Chlorella vulgaris biofilms at various developmental stages. Algal Res 38:101408. https://doi.org/10.1016/j.algal.2019.101408

Robles A, Capson-Tojo G, Galès A, Ruano VM, Sialve B, Ferrer J, Steyer JP (2020) Microalgae-bacteria consortia in high-rate ponds for treating urban wastewater: elucidating the key state indicators under dynamic conditions. J Environ Manage 261:110244. https://doi.org/10.1016/j.jenvman.2020.110244

Romero VGI, Fiamengo M, Acién FFG, Molina GE (2017) Outdoor production of microalgae biomass at pilot-scale in seawater using centrate as the nutrient source. Algal Res 25:538–548. https://doi.org/10.1016/j.algal.2017.06.016

Romero VGI, Fiamengo M, Acién FFG, Molina GE (2018) Utilization of centrate for the outdoor production of marine microalgae at the pilot-scale in raceway photobioreactors. J Environ Manage 228:506–516. https://doi.org/10.1016/j.jenvman.2018.08.020

Romero-Frasca E, Velasquez-Orta SB, Escobar-Sánchez V, Tinoco-Valencia R, Orta Ledesma MT (2021) Bioprospecting of wild type ethanologenic yeast for ethanol fuel production from wastewater-grown microalgae. Biotechnol Biofuels 14:93. https://doi.org/10.1186/s13068-021-01925-x

Sager JC, McFarlane JC (1997) Radiation - Chapter 1. In: Langhans RW, Tibbitts TW (eds) Plant growth chamber handbook. Iowa State University of Science and Technology, Ames, pp 1–30. https://doi.org/10.1023/A:1006995714717

Salama ES, Kurade MB, Abou-Shanab RAI, El-Dalatony MM, Yanga IS, Min B, Jeon BH (2017) Recent progress in microalgal biomass production coupled with wastewater treatment for biofuel generation. Renew Sust Energ Rev 79:1189–1211. https://doi.org/10.1016/j.rser.2017.05.091

Sánchez A, Garrido JA, Gómez C, Morales M, Acién-Fernández FG, Fernández JM, Molina E (2020) Year-long assessment of a pilot-scale thin-layer reactor for microalgae wastewater treatment. Variation in the microalgae-bacteria consortium and the impact of environmental conditions. Algal Res 50:101983. https://doi.org/10.1016/j.algal.2020.101983

Santos FM, Gonçalves AL, Pires JC (2019) Negative emission technologies. In: Bioenergy with carbon capture and storage. Academic Press, p 1e13

Schade S, Meier T (2019) A comparative analysis of the environmental impacts of cultivating microalgae in different production systems and climatic zones: a systematic review and meta-analysis. Algal Res 40:101485. https://doi.org/10.1016/j.algal.2019.101485

Silkina A, Ginnever EN, Fernandes F, Fuentes-Grünewald C (2019) Large-scale waste bio-remediation using microalgae cultivation as a platform. Energies 12:2772. https://doi.org/10.3390/en12142772

Sudhakar MP, Kumar BR, Mathimani T, Arunkumar K (2019) A review on bioenergy and bioactive compounds from microalgae and macroalgae-sustainable energy perspective. J Clean Prod 228:1320–1333. https://doi.org/10.1016/j.jclepro.2019.04.287

SundarRajan PS, Gopinath KP, Greetham D, Antonysamy AJ (2019) A review on cleaner production of biofuel feedstock from integrated CO2 sequestration and wastewater treatment system. J Clean Prod 210:445–458. https://doi.org/10.1016/j.jclepro.2018.11.010

Suparmaniama U, Lama KM, Uemura Y, Lim WJ, Leed TK, Shuit HS (2019) Insights into the microalgae cultivation technology and harvesting process for biofuel production: a review. Renew Sust Energ Rev 115:109361. https://doi.org/10.1016/j.rser.2019.109361

Sutherland DL, Turnbull MH, Craggs RJ (2014) Increased pond depth improves algal productivity and nutrient removal in wastewater treatment high rate algal ponds. Water Res 53:271–281. https://doi.org/10.1016/j.watres.2014.01.025

Sutherland DL, Park J, Heubeck S, Ralph PJ, Craggs RJ (2020a) Size matters – microalgae production and nutrient removal in wastewater treatment high rate algal ponds of three different sizes. Algal Res 45:101734. https://doi.org/10.1016/j.algal.2019.101734

Sutherland DL, Park J, Ralph PJ, Craggs RJ (2020b) Improved microalgal productivity and nutrient removal through operating wastewater high rate algal ponds in series. Algal Res 47:101850. https://doi.org/10.1016/j.algal.2020.101850

Takabe Y, Hidaka T, Tsumori J, Minamiyama M (2016) Effects of hydraulic retention time on cultivation of indigenous microalgae as a renewable energy source using secondary effluent. Bioresource Technol 207:399–408. https://doi.org/10.1016/j.biortech.2016.01.132

Toro-Huertas EI, Franco-Morgado M, de los Cobos Vasconcelos D, González-Sánchez A (2019) Photorespiration in an outdoor alkaline open-photobioreactor used for biogas upgrading. Sci Total Environ 667:613–621. https://doi.org/10.1016/j.scitotenv.2019.02.374

Udaiyappan AFM, Hasan HA, Takriff MS, Abdullah SRS (2017) A review of the potentials, challenges and current status of microalgae biomass applications in industrial wastewater treatment. J Water Process Eng 20:8–21. https://doi.org/10.1016/j.jwpe.2017.09.006

Valeriano González MT, Orta Ledesma MT, Velásquez Orta SB, Monje Ramírez I (2020) Harvesting of microalgae using ozone-air flotation for recovery of biomass, lipids, carbohydrates, and proteins. Env Tech 42(21):3267–3277. https://doi.org/10.1080/09593330.2020.1725144

Van Den Hende S, Beelen V, Julien L, Lefoulon A, Vanhoucke T, Coolsaet C, Sonnenholzner S, Vervaeren H, Rousseau DPL (2016) Technical potential of microalgal bacterial floc raceway ponds treating food-industry effluents while producing microalgal bacterial biomass: an outdoor pilot-scale study. Bioresource Technol 218:969–979. https://doi.org/10.1016/j.biortech.2016.07.065

Vassilev SV, Vassileva CG (2016) Composition, properties and challenges of algae biomass for biofuel application: an overview. Fuel 181:1–33. https://doi.org/10.1016/j.fuel.2016.04.106

Vielma Hernández E, Monje-Ramírez I, Velásquez-Orta SB, Gracia-Fadrique J, Orta Ledesma MT (2022) Surface activity of biomolecules released from microalgae harvested by ozone-flotation. Environ Technol Innov 26:102354. https://doi.org/10.1016/j.eti.2022.102354

Walls L, Velasquez S, Romero E, Leary P, Yañez I, Orta M (2019) Non-sterile heterotrophic cultivation of native wastewater yeast and microalgae for integrated municipal wastewater treatment and bioethanol production. Biochem Eng J 151:107319. https://doi.org/10.1016/j.bej.2019.107319

Wang L et al (2010) Cultivation of green algae Chlorella sp. in different wastewaters from municipal wastewater treatment plant. Appl Biochem Biotechnol 162:1174–1186. https://doi.org/10.1007/s12010-009-8866-7

Wen X, Du K, Wang Z, Peng X, Luo L, Tao H, Xu Y, Zhang D, Geng Y, Li Y (2016) Effective cultivation of microalgae for biofuel production: a pilot-scale evaluation of a novel oleaginous microalgae Graesiella sp. WBG-1. Biotechnol Biofuels 9:123. https://doi.org/10.1186/s13068-016-0541-y

Wrede D, Hussainy SU, Rajendram W, Gray S (2018) Investigation and modelling of high rate algal ponds utilising secondary effluent at Western water, Bacchus Marsh recycled water plant. Water Sci Technol 8(1):0-30 https://doi.org/10.2166/wst.2018.202

Xu X, Gub X, Wang Z, Shatner W, Wang Z (2019) Progress, challenges and solutions of research on photosynthetic carbon sequestration efficiency of microalgae. Renew Sust Energ Rev 110:65–82. https://doi.org/10.1016/j.rser.2019.04.050

Zhang TY, Hu HY, Wu YH, Zhuang LL, Xu XQ, Wang XX, Dao GH (2016) Promising solutions to solve the bottlenecks in the large-scale cultivation of microalgae for biomass/bioenergy production. Renew Sust Energ Rev 60:1602–1614. https://doi.org/10.1016/j.rser.2016.02.008

Zhou W, Wang J, Chen P, Ji C, Kang Q, Lu B, Li K, Liu J, Ruan R (2017) Bio-mitigation of carbon dioxide using microalgal systems: advances and perspectives. Renew Sust Energ Rev 76:1163–1175. https://doi.org/10.1016/j.rser.2017.03.065

Acknowledgements

The authors gratefully acknowledge E. J. Vargas Yáñez for his support in the design and elaboration of the figures of this paper.

Funding

This work was supported by Instituto de Ingeniería of the Universidad Nacional Autónoma de México, Project 3307: “Intensification of processes for obtaining biocomposites from wastewater”. Call 2023- Interdisciplinary Research Groups (GII-IIUNAM).

Author information

Authors and Affiliations

Contributions

S.B.V.O.: conception, data collection and analysis, manuscript writing, responsible for ensuring manuscript descriptions are accurate, and corresponding author. I.Y.N.: writing—review and editing, provided critical revision of the article, preparation, creation, and presentation of the published work. I.M.R.: provided critical revision of the article. All the authors approved the final version of the manuscript, and all have agreed to this submission. M.T.O.L.: developed the concept of this research, supervised the progress and design of this research, and revised manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval and consent to participate

No human participants or animals were involved. As such, no consent to publish is required.

Additional information

Responsible Editor: Guilherme Luiz Dotto

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Dedicatory

This article is dedicated to Mrs. Andrea Hernández García who initially contributed to the retrieval of literature and passed away in 2022, in the middle of her youth. She was an excellent enthusiastic and committed doctorate candidate. Her science contributions will not ever be forgotten.

Highlights

1) A multivariate analysis of pilot-scale HRAP using microalgae is presented.

2) Solar radiation and NH4+ loads explain 80% of the final biomass productivity in HRAP.

3) Specific growth rates decrease by half from laboratory to pilot-scale cultivations.

4) HRAP can effectively remove 90% of NH4, 70% of COD, and 50% of PO43− from wastewater.

5) High NH4+ concentrations increase microalgae yield but not necessarily productivity.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Velásquez-Orta, S.B., Yáñez-Noguez, I., Ramírez, I.M. et al. Pilot-scale microalgae cultivation and wastewater treatment using high-rate ponds: a meta-analysis. Environ Sci Pollut Res 31, 46994–47021 (2024). https://doi.org/10.1007/s11356-024-34000-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-34000-7