Abstract

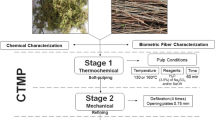

Pines play a significant role in forest biodiversity globally and generate huge forest litter. Dry pine needles due to low ignition temperature and high frictional force with the ground catch fire quickly. Annual forest fires in the northern states of India greatly impact the Indian economy besides causing huge loss to biodiversity, livelihood, and environment. Pine needles are also considered unfit for fodder consumption due to presence of tannins. Although the presence of softwood lignin in pine needles makes it difficult to degrade easily, the presence of holocellulose (68.5%) containing 45–51% cellulose makes this biomass a potential substrate to be used in pulp-making industries for low-grade paper sheets. The good fiber length of pine needles (1.3–1.4 mm) with a diameter of 30–32 μm, maybe considered important property for paper making. The use of pine needles in the pharmaceutical and food industries are due to the presence of secondary metabolites (α-pinene, β-pinene, caryophyllene etc.). The various other potential applications of pine needles are for producing bio-ethanol (yield, 3.98%; purity, 94%), biogas (yield, 23.1 L kg−1), smokeless briquettes (calorific value, 18.77 MJ kg−1), biochar (calorific value, 25.6 MJ kg−1), bio-composites (tensile strength, 21–60 MPa), and bio-pesticides. This paper comprehensively reviews the current applications of pine needles along with its future prospective applications that can have the dual advantage of providing employment opportunities to the people along with environmental protection.

Similar content being viewed by others

References

Abd-Elhamid AI, Emran M, El-Sadek MH, El-Shanshory AA, Soliman H, Akl MA, Rashad M (2020) Enhanced removal of cationic dye by eco-friendly activated biochar derived from rice straw. Appl Water Sci 10(1):1–11

Ahmad R, Khuroo AA, Hamid M, Rashid I, Rather ZA (2021) Disentangling the determinants of litter decomposition among invaded and uninvaded habitats: a field experiment from the Kashmir Himalaya. Acta Oecologica 110:103708

Ahmad M, Lee SS, Rajapaksha AU, Vithanage M, Zhang M, Cho JS ... & Ok YS (2013) Trichloroethylene adsorption by pine needle biochars produced at various pyrolysis temperatures. Bioresource Technol 143:615–622

Ahmed MB, Zhou JL, Ngo HH, Guo W (2016) Insight into biochar properties and its cost analysis. Biomass Bioenerg 84:76–86

Alzebdeh KI, Nassar MM, Arunachalam R (2019) Effect of fabrication parameters on strength of natural fiber polypropylene composites: statistical assessment. Measurement 146:195–207

Anastopoulos I, Katsouromalli A, Pashalidis I (2020) Oxidized biochar obtained from pine needles as a novel adsorbent to remove caffeine from aqueous solutions. J Mol Liq 304:112661

Baishya R, Barik SK (2011) Estimation of tree biomass, carbon pool and net primary production of an old-growth Pinus kesiya Royle ex Gordon forest in north-eastern India. Annal For Sci 68(4):727–736

Bajpai PK, Singh I, Madaan J (2014) Development and characterization of PLA-based green composites: a review. J Thermoplast Compos Mater 27(1):52–81. https://doi.org/10.1177/0892705712439571

Barton-Pudlik JM, Czaja K (2016) Conifer needles as thermoplastic composite fillers: structure and properties. BioResources 11(3):6211–6231

Behera S, Arora R, Nandhagopal N, Kumar S (2014) Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew Sustain Energy Rev 36:91–106

Bhagat M, Bandral A, Bashir M, Bindu K (2018) GC–MS analysis of essential oil of Pinus roxburghii Sarg(Chir pine) needles and evaluation of antibacterial and anti-proliferative properties. Indian J Natural Prod Resour (IJNPR) 9(1):34–38

Bharti V, Awasthi M (2013) Pine needle charcoal briquettes: rural technology option in pine forest Region. Int J Power Syst Oper Energy Manag 2(1):2

Bisht AS, Thakur NS (2020) Pine needles biomass gasification based electricity generation for Indian Himalayan region: drivers and barriers. In Green Buildings and Sustainable Engineering 47–59. Springer, Singapore

Borowski G (2011) Possibilities of utilization of energy briquettes. Electr Eng Res Rep 1(27):48–51

Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, Cansell F, Aymonier C (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenerg 35(1):298–307

Chauhan M, Gupta M, Singh B, Singh AK, Gupta VK (2012) Pine needle/isocyanate composites: dimensional stability, biological resistance, flammability, and thermoacoustic characteristics. Polym Compos 33(3):324–335

Chen Y, Yang G, Sweeney S, Feng Y (2010) Household biogas use in rural China: a study of opportunities and constraints. Renew Sustain Energy Rev 14(1):545–549

Choudhary V, Patel M, Pittman CU Jr, Mohan D (2020) Batch and continuous fixed-bed lead removal using himalayan pine needle biochar: isotherm and kinetic studies. ACS Omega 5(27):16366–16378

Choudhary A, Kumar A, Kumar S, Govil T, Sani RK (2023) Enhanced biogas production from pine litter codigestion with food waste, microbial community, kinetics, and technoeconomic feasibility. J Environ Eng 149(1):04022089

Dar BA, Wani A, Rather SA, Singh B (2013) Isothermal studies of sorption of acetic acid from waste water using shed needles from pine trees. Arab J Sci Eng 38(10):2595–2599

Daystar J, Reeb C, Venditti R, Gonzalez R, Puettmann ME (2012) Life-cycle assessment of bioethanol from pine residues via indirect biomass gasification to mixed alcohols. For Prod J 62(4):314–325

Dobriyal MJR, Bijalwan A, Dobriyal MJ (2017) ‘Forest fire in western Himalayas of India: a review’, New York Sci J 10(6) https://doi.org/10.7537/marsnys100617.06.Keywords

Dwivedi RK, Singh RP, Bhattacharya TK (2016) Studies on bio-pretreatment of pine needles for sustainable energy thereby preventing wild forest fires. Curr Sci 388–394

Feng S, Zeng W, Luo F, Zhao J, Yang Z, Sun Q (2010) Antibacterial activity of organic acids in aqueous extracts from pine needles (Pinus massoniana Lamb). Food Sci Biotechnol 19(1):35–41

Foti V, Araniti F, Manti F, Alicandri E, Giuffrè AM, Bonsignore CP ... & Badiani M (2020) Profiling volatile terpenoids from calabrian pine stands infested by the pine processionary moth. Plants 9(10):1362

Gairola S, Gairola S, Sharma H, Rakesh PK (2019) Impact behavior of pine needle fiber/pistachio shell filler based epoxy composite. In Journal of Physics: Conference Series 1240, 1 012096. IOP Publishing

Galdina T, Khazova E (2019) Adaptability of Pinus sylvestris L. to various environmental conditions. In IOP Conference Series: Earth and Environmental Science (Vol. 316, No. 1, p. 012002). IOP Publishing.

Gartner FR, Johnson FD, Morgan P (2019) Cattle abortion from ponderosa pine needles: ecological and range management considerations. In The Ecology and Economic Impact of Poisonous Plants on Livestock Production (pp. 71–93). CRC Press.

Grierson AJC, Long DG, Page CN (1980) Notes relating to the flora of Bhutan:(III). Pinus bhutanica: a new 5-needle pine from Bhutan and India. Notes Royal Botanic Garden Edinburgh 38(2):297–310

Gullilat, H., k Saini, A., Kumari, R., Chandan, G., & Saini, R. V. (2021). Pinus roxburghii constituents augment human lymphocytes mediated cytotoxicity towards cancer cells. Pharmaceutical Sciences, 27(4), 543–551.

Hjouji K, Atemni I, Mehdaoui I, Ainane A, Berrada S, Rais Z, ... & Ainane T (2021) Essential oil of aleppo pine needles: antioxidant and antibacterial activities

Ioannou E et al (2014) The genus Pinus: a comparative study on the needle essential oil composition of 46 pine species. Phytochem Rev 13(4):741–768. https://doi.org/10.1007/s11101-014-9338-4

Irfan M, Nadeem M, Syed Q, Qazi JI (2016) Statistical optimization of dilute acid pretreatment of pinus needles to be used as substrate for biofuel production. Energy Sources Part a: Recover Utilization Environ Eff 38(14):1983–1992

Jeon C, Solis KL, An HR, Hong Y, Igalavithana AD, Ok YS (2020) Sustainable removal of Hg (II) by sulfur-modified pine-needle biochar. J Hazard Mater 388:122048

Joshi K, Sharma V, Mittal S (2015) Social entrepreneurship through forest bioresidue briquetting: an approach to mitigate forest fires in Pine areas of Western Himalaya, India. Renew Sustain Energy Rev 51:1338–1344

Kadam AA, Singh S, Gaikwad KK (2021) Chitosan based antioxidant films incorporated with pine needles (Cedrus deodara) extract for active food packaging applications. Food Control 124:107877

Kala LD, Subbarao PMV (2018) Estimation of pine needle availability in the Central Himalayan state of Uttarakhand, India for use as energy feedstock. Renew Energy 128:9–19

Karlsson H (2010) Strength properties of paper produced from softwood kraft pulp – pulp mixture, reinforcement and sheet stratification, Karlstad University Faculty of Technology and Science Chemical Engineering.

Kaur K, Phutela UG (2016) Enhancement of paddy straw digestibility and biogas production by sodium hydroxide-microwave pretreatment. Renew Energy 92:178–184

Khan A, Rashid A, Younas R (2015) Adsorption of reactive black-5 by pine needles biochar produced via catalytic and non-catalytic pyrolysis. Arab J Sci Eng 40(5):1269–1278

Khan IU, Shah AA, Sahibzada FA, Hayyat A, Nazar M, Mobashar M, ... & Sultana N (2019) Carcass characteristics and serum biochemical profile of Japanese quail by the supplementation of pine needles and vitamin E powder. Biologia 74(8):993–1000

Koutsaviti A, Toutoungy S, Saliba R, Loupassaki S, Tzakou O, Roussis V, Ioannou E (2021) Antioxidant potential of pine needles: a systematic study on the essential oils and extracts of 46 species of the genus Pinus. Foods 10(1):142

Kulshrestha S, Khan SH (2019) Identification and characterization of secondary metabolites isolated from the leaves of Pinus roxburghii (Sarg.). J Pharmacogn Phytochem 8(1):2028–2034

Kumar V, Nanda M, Verma M, Singh A (2018) An integrated approach for extracting fuel, chemicals, and residual carbon using pine needles. Biomass Convers Biorefinery 8(2):447–454

Kumar A, Gupta V, Singh S, Saini S, Gaikwad KK (2021) Pine needles lignocellulosic ethylene scavenging paper impregnated with nanozeolite for active packaging applications. Ind Crops Prod 170:113752

Kumari P, Mohanty B (2020) Hydrogen-rich gas production with CO2 capture from steam gasification of pine needle using calcium oxide: experimental and modeling study. Int J Energy Res 44(8):6927–6938

Kumari N, Chhabra T, Kumar S, Krishnan V (2022) Nanoarchitectonics of sulfonated biochar from pine needles as catalyst for conversion of biomass derived chemicals to value added products. Catal Commun 168:106467

Lal PS, Sharma A, Bist V (2013) Pine needle - an evaluation of pulp and paper. J For Prod Ind 2(3):42–47

Lee, H. J., Park, M., Choi, H., Nowakowska, A., Moon, C., Kwak, J. H., & Kim, Y. B. (2021). Pine needle extract applicable to topical treatment for the prevention of human papillomavirus infection.

Li B, Dong R, Gao L, Yang J, Shi QF, Guo WH (2011) Toughening and crystallization behavior of poly (lactic acid)/wood flour composite. Polym Mater Sci Eng 27:33–36

Li W, Zhang Z, Du C, Wang G (2020) Study on adsorption performance of pine needle biochar on rhodamine B. In IOP Conference Series: Materials Science and Engineering (Vol. 729, No. 1, p. 012076). IOP Publishing

Liu, H. N., Hsu, T. W., Wu, Y. H., & Huang, C. L. (2021). Unraveling microbiomes associated with decomposition of needles of two Pinus species with contrasting fire-adaptive strategies. Biology and Fertility of Soils, 57(5), 715-729.

Long W, Wang Y (2021) Effect of pine needle fibre reinforcement on the mechanical properties of concrete. Constr Build Mater 278:122333

López R, Climent J, Gil L (2008) From desert to cloud forest: the non-trivial phenotypic variation of Canary Island pine needles. Trees 22(6):843–849

Mahajan D, Bhat ZF, Kumar S (2016) Pine needles (Cedrus deodara (Roxb.) Loud.) extract as a novel preservative in cheese. Food Packag Shelf Life 7:20–25

Mahajan R, Nikitina A, Litti Y, Kallistova A, Nozhevnikova A, Goel G (2019) Evaluating anaerobic and aerobic digestion strategies for degradation of pretreated pine needle litter. Int J Environ Sci Technol 16(1):191–200

Mandal S, Bhattacharya TK, Verma AK, Haydary J (2018) Optimization of process parameters for bio-oil synthesis from pine needles (Pinus roxburghii) using response surface methodology. Chem Pap 72(3):603–616

Mandal S, Haydary J, Gangil S, Husar J, Jena PC, Bhattacharya TK (2020) Inferences from thermogravimetric analysis of pine needles and its chars from a pilot-scale screw reactor. Chem Pap 74(2):689–698

Mani S, Tabil LG, Sokhansanj S (2006) Specific energy requirement for compacting corn stover. Biores Technol 97(12):1420–1426

Mankar AR, Pandey A, Modak A, Pant KK (2021) Pretreatment of lignocellulosic biomass: a review on recent advances. Biores Technol 334:125235

Meenakshisundaram S, Fayeulle A, Leonard E, Ceballos C, Pauss A (2021) Fiber degradation and carbohydrate production by combined biological and chemical/physicochemical pretreatment methods of lignocellulosic biomass–a review. Biores Technol 331:125053

Mengual A, Juárez D, Balart R, Ferrándiz S (2017) Mechanical characterization of composite materials based on pine needle residues processed by thermocompression. Procedia Manufacturing 13:315–320

Mohan C, Annachhatre A (2023) Role of pine needle biochar in operation and stability of anaerobic processes. Biodegradation 34(1):53–71

Negi S (2017) Pretreatment strategies of lignocellulosic biomass towards ethanol yield: case study of pine needles. In Biofuels (pp. 85–102). Springer, Singapore

Neis FA et al (2018) ‘Multiple industrial uses of non-wood pine products.’ Ind Crops Prod 130:248–258. https://doi.org/10.1016/j.indcrop.2018.12.088

Nicolaou E, Philippou K, Anastopoulos I, Pashalidis I (2019) Copper adsorption by magnetized pine-needle biochar. Processes 7(12):903

Nurek T, Gendek A, Roman K, Dąbrowska M (2019) The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass Bioenerg 130:105368

Pandey S, Dhakal RP (2013) Pine needle briquettes: a renewable source of energy. Int J Energy Sci 3(3):254–260

Pandey AK, Negi S (2015) Impact of surfactant assisted acid and alkali pretreatment on lignocellulosic structure of pine foliage and optimization of its saccharification parameters using response surface methodology. Biores Technol 192:115–125

Park YS, Jeon MH, Hwang HJ, Park MR, Lee SH, Kim SG, Kim M (2011) Antioxidant activity and analysis of proanthocyanidins from pine (Pinus densiflora) needles. Nurs Res Pract 5(4):281–287

Philippou K, Anastopoulos I, Dosche C, Pashalidis I (2019) Synthesis and characterization of a novel Fe3O4-loaded oxidized biochar from pine needles and its application for uranium removal. Kinetic, thermodynamic, and mechanistic analysis. J Environ Manag 252:109677

Pokharel P, Kwak JH, Chang SX (2017) Growth and nitrogen uptake of jack pine seedlings in response to exponential fertilization and weed control in reclaimed soil. Biol Fertil Soils 53(6):701–713

Proboningrat A, Fadholly A, Sudjarwo SA, Rantam FA, Achmad AB (2021) The cytotoxic activity of pine needles ethanolic extract of Pinus merkusii on HeLa cell lines. In BIO Web of Conferences (Vol. 33, p. 03001). EDP Sciences

Reddy Marella JB, Madireddy S and Maripi AN (2014) ‘Production of pulp from banana pseudo stem for grease proof paper’, Int J Eng Res Gen Sci 2(1):61–77. Available at: https://www.ijergs.org

Sable I et al (2012) Comparison of the properties of wood and pulp fibers from lodgepole pine (Pinus contorta) and scots pine (Pinus sylvestris). BioResources 7(2):1771–1783. https://doi.org/10.15376/biores.7.2.1771-1783

Sahin H, Yalcin O (2017) Chemical composition and utilization of conifer needles-a review. J Appl Life Sci Int 14(3):1–11. https://doi.org/10.9734/jalsi/2017/37076

Sahu TK, Sahu VK, Mondal A, Shukla PC, Gupta S, Sarkar S (2022) Investigation of sugar extraction capability from rice paddy straw for potential use of bioethanol production towards energy security. Energy Sources Part a: Recover Utilization Environ Eff 44(1):272–286

Salehian P, Karimi K, Zilouei H, Jeihanipour A (2013) Improvement of biogas production from pine wood by alkali pretreatment. Fuel 106:484–489

Salem MZM, Ali HM, Basalah MO (2014) Essential oils from wood, bark, and needles of Pinus roxburghii Sarg. from Alexandria, Egypt: antibacterial and antioxidant activities. BioResources 9(4):7454–7466. https://doi.org/10.15376/biores.9.4.7454-7466

Sengar A, Sharma V, Agrawal R, Dwivedi A, Dwivedi P, Joshi K, ... & Barthwal M (2020) Prioritization of barriers to energy generation using pine needles to mitigate climate change: evidence from India. J Clean Prod 275:123840

Shadkami F, Helleur RJ, Cox RM (2007) Profiling secondary metabolites of needles of ozone-fumigated white pine (Pinus strobus) clones by thermally assisted hydrolysis/methylation GC/MS. J Chem Ecol 33(7):1467–1476

Sharma, Nivedita, Mahajan, S. and Sharma, Nisha., 2012 ‘Evaluation of different forest wastes of Northern Himalayas as a potential substrate for cellulase production by Aspergillus niger F7 and its partial purification’, 18(4), pp. 324–335. Available at: http://.

Sharma, A., Sharma, L., & Goyal, R. (2018). A review on himalayan pine species: Ethnopharmacological, phytochemical and pharmacological aspects. Pharmacognosy Journal, 10(4).

Silori, G. K., Kushwaha, N., & Kumar, V. (2019). Essential oils from pines: Chemistry and applications. Essential oil research: Trends in biosynthesis, analytics, industrial applications and biotechnological production, 275–297.https://doi.org/10.1007/978-3-030-16546-8_10

Singh G, Giri A, Paul S (2017) Pinus roxburghii Sarg.(Chir Pine): a valuable forest resource of Uttarakhand. Indian For 143(7):700–709

Singh S, Adak A, Saritha M, Sharma S, Tiwari R, Rana S, ... & Nain L (2017a) Bioethanol production scenario in India: potential and policy perspective. In Sustainable Biofuels Development in India (pp. 21–37). Springer, Cham

Singh P, Sharma NK (2021) Utilization of sludge co-digested with pine needles for the generation of biogas. Int J Adv Res Eng Technol (IJARET) 12(4):159–170

Sinha P, Mathur S, Sharma P, Kumar V (2018) Potential of pine needles for PLA-based composites. Polym Compos 39(4):1339–1349

Slathia PS et al (2020) Dilute acid pretreatment of pine needles of Pinus roxburghii by response surface methodology for bioethanol production by separate hydrolysis and fermentation. Biomass Convers Biorefinery 10(1):95–106. https://doi.org/10.1007/s13399-019-00433-1

Stolter C, Niemelä P, Ball JP, Julkunen-Tiitto R, Vanhatalo A, Danell K, ... & Ganzhorn JU (2009) Comparison of plant secondary metabolites and digestibility of three different boreal coniferous trees. Basic Appl Ecol 10(1):19–26

Sukarno, A., Zairina, A., Quarta, Y., Kurniasari, R., Sumardi, S., & Leksono, A. S. (2020). Yield and components of Pine (Pinus merkusii) Turpentine among age class differences tapping by borehole method. Indonesian Journal of Environment and Sustainable Development, 11(1).

Suri, P., Dwivedi, D., Rathour, R. K., Rana, N., Sharma, V., Bhatia, R. K., & Bhatt, A. K. (2021). Enhanced C-5 sugar production from pine needle waste biomass using Bacillus sp. XPB-11 mutant and its biotransformation to bioethanol. Biomass Conversion and Biorefinery, 1–10.

Thakur VK, Thakur MK, Gupta RK (2014) Review: raw natural fiber-based polymer composites. Int J Polym Anal Charact 19(3):256–271. https://doi.org/10.1080/1023666X.2014.880016

Tiwari SP et al (2013) Comparative morphological, epidermal, and anatomical studies of Pinus roxburghii needles at different altitudes in the North-West Indian Himalayas. Turk J Bot 37(1):65–73. https://doi.org/10.3906/bot-1110-1

Tumuluru JS, Tabil LG, Song Y, Iroba KL, Meda V (2015) Impact of process conditions on the density and durability of wheat, oat, canola, and barley straw briquettes. Bioenergy Res 8(1):388–401

Turner GW, Parrish AN, Zager JJ, Fischedick JT, Lange BM (2019) Assessment of flux through oleoresin biosynthesis in epithelial cells of loblolly pine resin ducts. J Exp Bot 70(1):217–230

Tyukavina ON, Neverov NA, Klevtsov DN (2019) Influence of growing conditions on morphological and anatomical characteristics of pine needles in the northern taiga. J for Sci 65(1):33–39

Vaid S, Nargotra P, Bajaj BK (2018) Consolidated bioprocessing for biofuel-ethanol production from pine needle biomass. Environ Prog Sustain Energy 37(1):546–552

Varma AK, Mondal P (2018) Pyrolysis of pine needles: effects of process parameters on products yield and analysis of products. J Therm Anal Calorim 131(3):2057–2072

Verma B, Reddy MS (2020) Biochar augmentation improves ectomycorrhizal colonisation, plant growth and soil fertility. Soil Res 58(7):673–682

Wang Q, Han K, Gao J, Li H, Lu C (2017) The pyrolysis of biomass briquettes: effect of pyrolysis temperature and phosphorus additives on the quality and combustion of bio-char briquettes. Fuel 199:488–496

Wu Y, Bai J, Zhong K, Huang Y, Gao H (2017) A dual antibacterial mechanism involved in membrane disruption and DNA binding of 2R, 3R-dihydromyricetin from pine needles of Cedrus deodara against Staphylococcus aureus. Food Chem 218:463–470

Yaacab ND, Ismail H, Ting SS (2016) Potential use of paddy straw as filler in poly lactic acid/paddy straw powder biocomposite: thermal and thermal properties. Procedia Chem 19:757–762

Yadav, M., Siddique, J. A., Khan, A. A. P., Khan, A., & Asiri, A. M. (2021). Biofibers and Biopolymers for Biocomposites–in the Eyes of Spectroscopy. Biobased Composites: Processing, Characterization, Properties, and Applications.

Yan S, Chen H, Zhu H, Lin Z, Wu G, Gao W, ... & Wu Y (2023) Enhanced adsorption of bio-oil on activated biochar in slurry fuels and the adsorption selectivity. Fuel, 338:127224

Yi M, Jia T, Dong L, Zhang L, Leng C, Liu S, Lai M (2021) Resin yield in Pinus elliottii Engelm. is related to the resin flow rate, resin components and resin duct characteristics at three locations in southern China. Ind Crops Prod 160:113141

Zeng WC, He Q, Sun Q, Zhong K, Gao H (2012) Antibacterial activity of water-soluble extract from pine needles of Cedrus deodara. Int J Food Microbiol 153(1–2):78–84

Zheng Y, Zhao J, Xu F, Li Y (2014) Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci 42:35–53

Zulfqar, F., Akhtar, M. F., Saleem, A., Akhtar, B., Sharif, A., & Saleem, U. (2020). Chemical characterization, antioxidant evaluation, and antidiabetic potential of Pinus gerardiana (Pine nuts) extracts. Journal of food biochemistry, 44(6), e13199.

Funding

This work is supported by Indian Institute of Technology (IIT) Delhi and the University Grants Commission (UGC) (JRF of first author).

Author information

Authors and Affiliations

Contributions

Akansha Gupta: conceptualization, writing—original draft preparation; Pooja Ghosh: supervision, reviewing, and editing; Kalpana Arora: supervision, reviewing and editing; Satyawati Sharma: supervision, reviewing and editing, funding acquisition; Sunil Kumar: review editing.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable. Present study did not involve any human participants and human data.

Consent for publication

This study does not involve any human subjects. Authors have not submitted the manuscript to pre-print server before submitting it to Environment Science Pollution and Research.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gupta, A., Ghosh, P., Arora, K. et al. Valorization potential of pine needle waste biomass: recent trends and future perspectives. Environ Sci Pollut Res (2023). https://doi.org/10.1007/s11356-023-27440-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-023-27440-0